High-precision digital indicating gauge and adjusting method of position precision of main gate and auxiliary gate

An adjustment method and high-precision technology, which is applied in the field of high-precision digital display indicators and the adjustment of the position accuracy of the main and auxiliary grids, can solve the problems of low production efficiency, inability to adjust, waste of manpower and material resources, etc., to reduce production consumables, The effect of ensuring assembly accuracy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

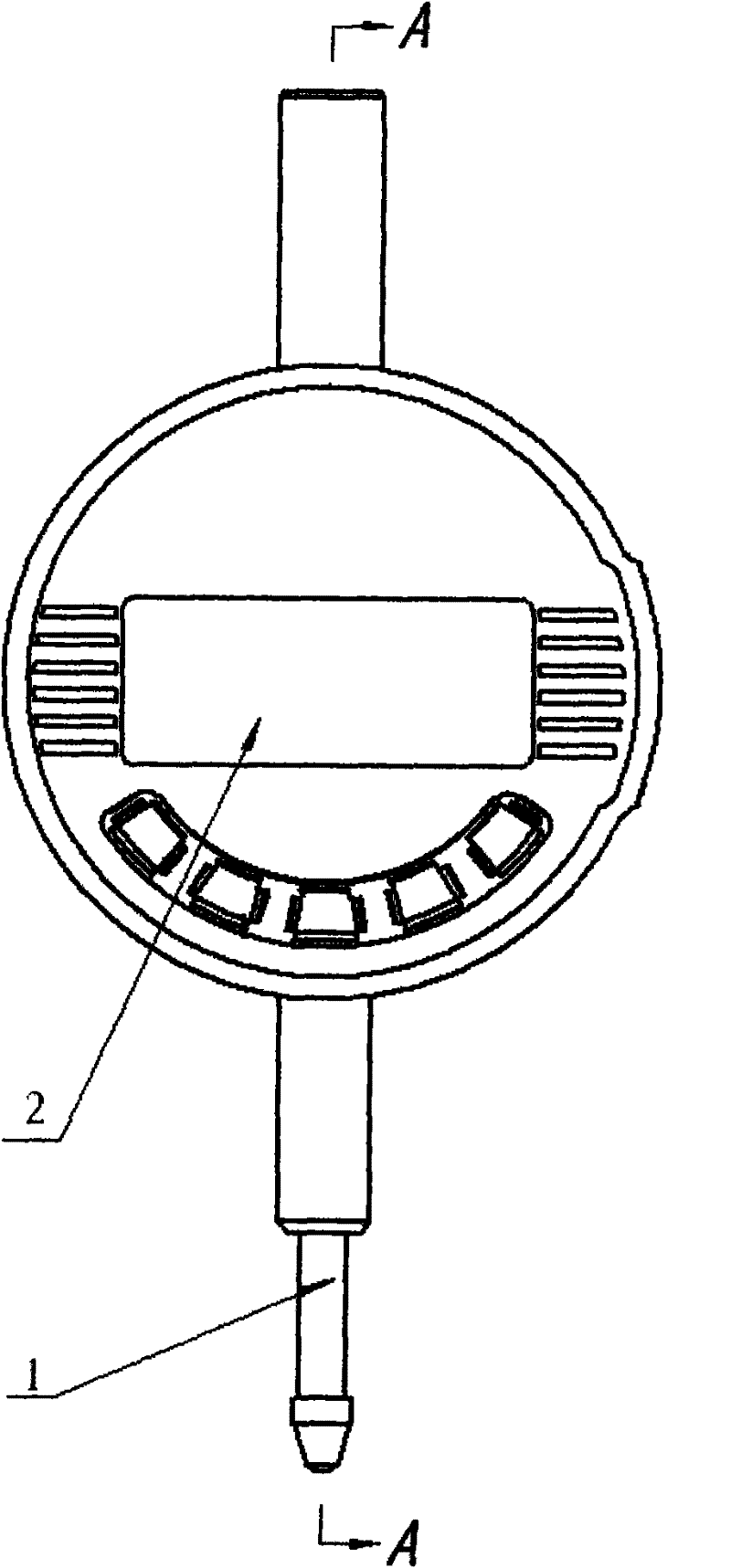

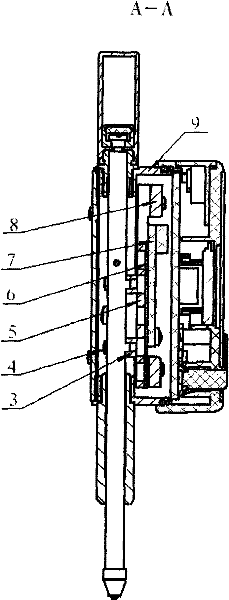

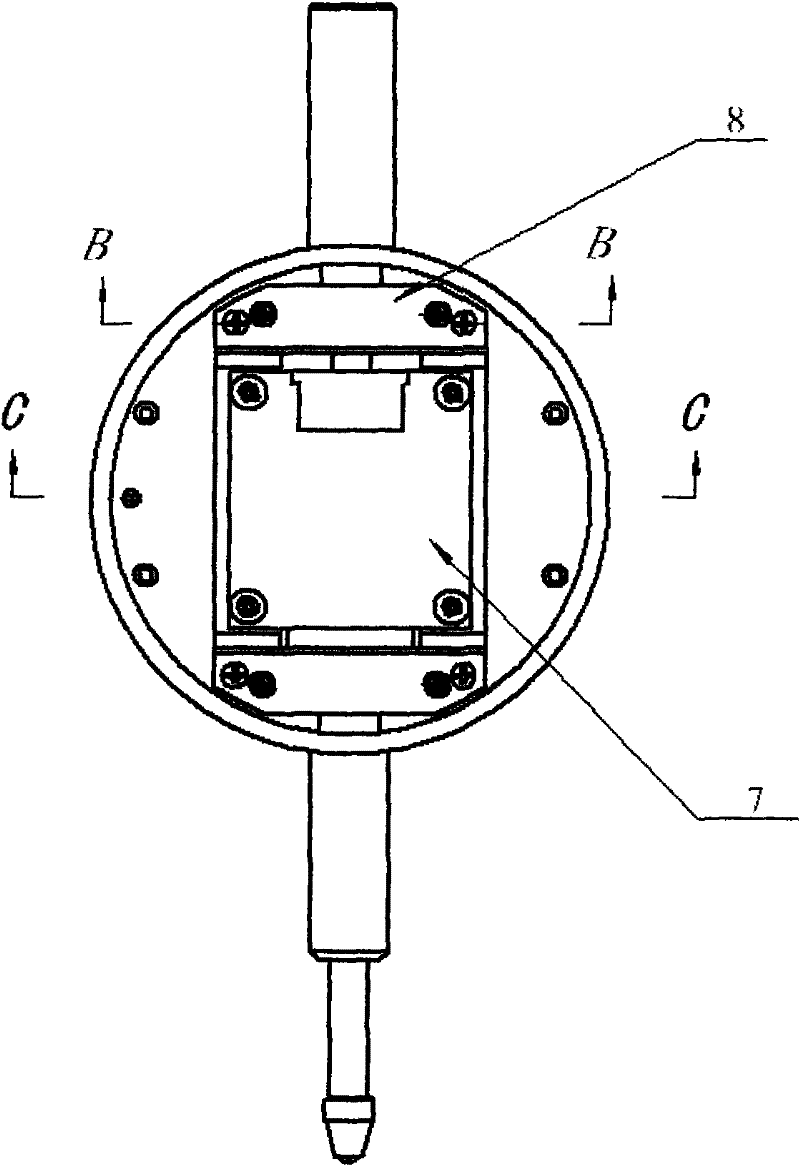

[0013] like figure 1 , figure 2 , Figure 4 , Figure 5 As shown, the measuring rod 1 is slidingly connected with the upper and lower shaft sleeves in the meter body part 9, the display assembly 2 is connected with the upper surface of the meter body in the meter body part 9 with screws, and the lower end of the balance plate 3 is connected to the middle part of the measuring rod 1 Connect with two cross-recessed set screws 4, connect the upper end with the auxiliary grid plate 5 with four connecting screws 12, bond the auxiliary grid 6 with the upper end of the auxiliary grid plate 5, and connect the main grid 7 with the main grid support 8 with screws , the main grid support 8 is connected with the watch body in the watch body part 9 by fastening screws 10 , and the adjustment screw 11 is threadedly connected with the main grid support 8 .

[0014] The adjustment method of the position accuracy of the main and auxiliary grids: the position of the auxiliary grid 6 is unch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com