Hand wheel component of temperature control valve

A technology of temperature control valve and handwheel, which is applied in the direction of valve details, valve devices, engine components, etc., can solve the problems of scattered transmission rods, failure of temperature control valves, and separation of adjustment handles, etc., so as to improve safety, use convenience, Humanized effect of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

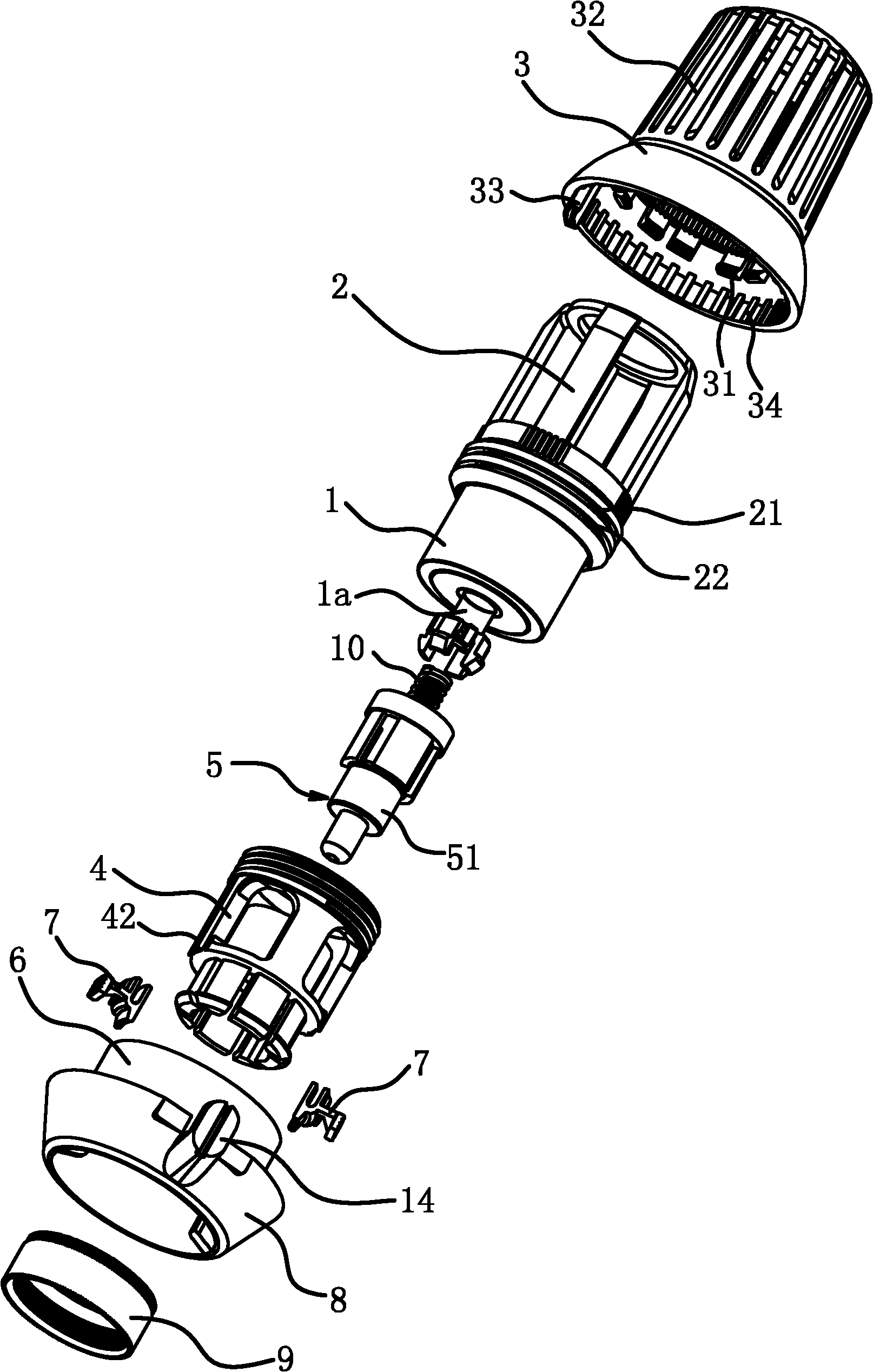

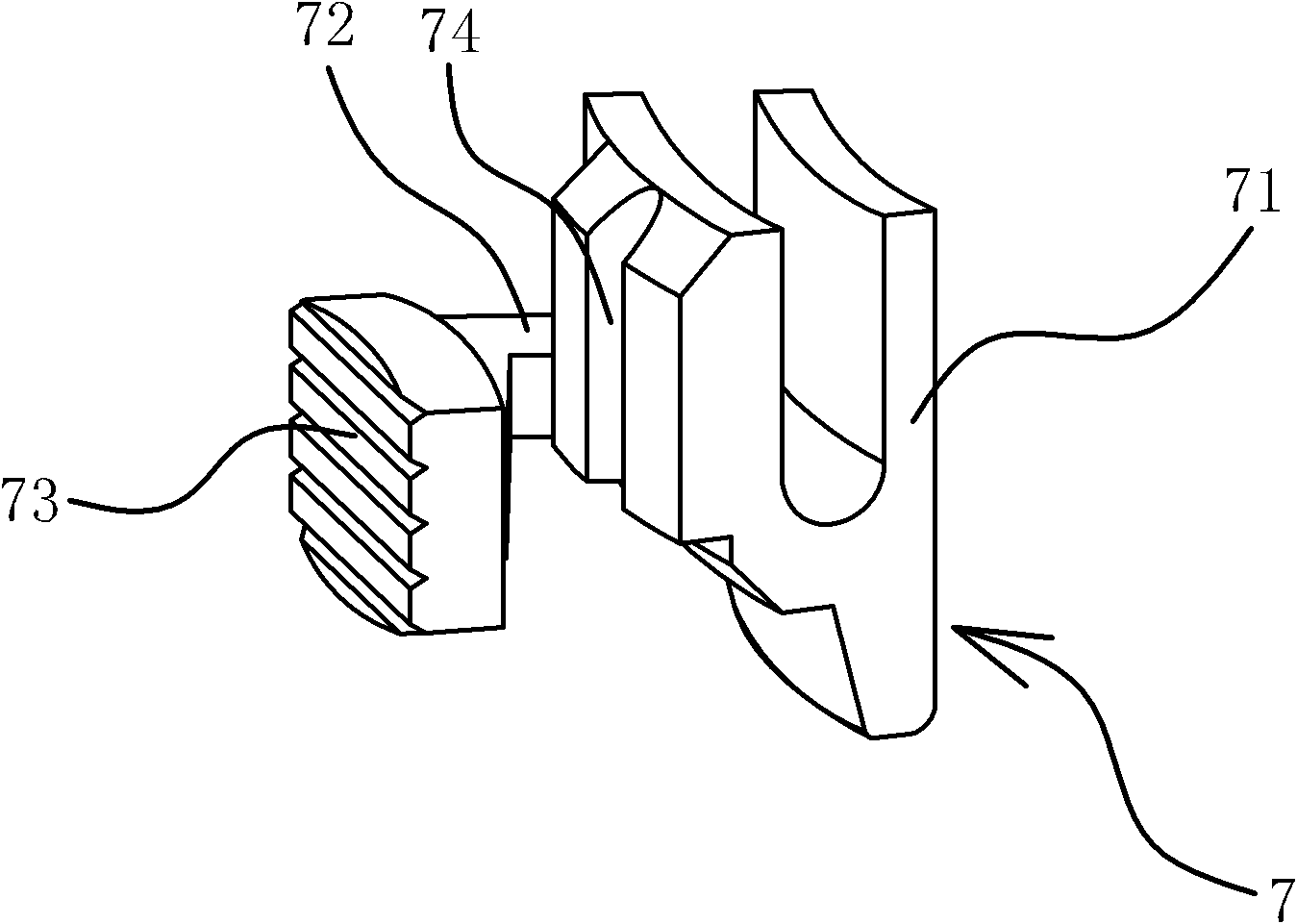

[0038] Such as Figure 1 to Figure 5 As shown, the temperature control valve handwheel assembly includes a temperature bulb 1, a fixing frame 2, a base 4, a housing 3, a limit mechanism and an identification mechanism.

[0039] Specifically, the base 4 is cylindrical, and one end of the base 4 is connected with a nut 9 for connecting the handwheel assembly with the temperature control valve, and the outer wall of one end of the base 4 is threaded.

[0040]The fixed frame 2 is cylindrical, and the temperature bulb 1 is fixed in the fixed frame 2. The opening of the fixed frame 2 and one end of the base 4 are connected by threads, and the free end of the temperature bulb 1 ejector rod 1a can abut against the fixed frame 2. superior. When the fixed frame 2 is rotated, the base 4 moves axially along the inner wall of the fixed frame 2, thereby adjusting the size of the cavity of the temperature bulb 1 for storing the heat-sensitive medium. The outer wall of the fixing frame 2 ha...

Embodiment 2

[0052] Such as Figure 10 to Figure 13 As shown, the structure and principle of this embodiment are basically the same as those of the first embodiment, except that the limiting mechanism includes a stop bar 61 , a stop block 33 and a limit ring 15 . Specifically, the retaining bar 61 is fixed on the outer wall of the base 4, and the stopper 33 is fixed on the inner wall of the bottom of the housing 3, and when the housing 3 is rotated to rotate relative to the base 4, the two sides of the stopper 33 can respectively It abuts against the two side surfaces of the retaining strip 61 in a one-to-one correspondence.

[0053] The limiting ring 15 is sleeved on the base 4 , so the limiting ring 15 can move circumferentially along the outer wall of the base 4 , and can also move axially along the outer wall of the base 4 . The bottom surface of the housing 3 has an annular groove 16, the axis of the annular groove 16 coincides with the axis of the base 4, and one end surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com