Locating correction method for improving coaxiality of bonded dual-pedal bearing inner rings

A technology of positioning correction and bearing inner ring, which is applied in the field of bearing processing, can solve the problems of high processing cost, high reject rate, and low production efficiency, and achieve the effects of high positioning quality, convenient operation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The outer diameter of the A-lobe inner ring 1 and the outer diameter of the B-lobe inner ring 2 are either equal or unequal.

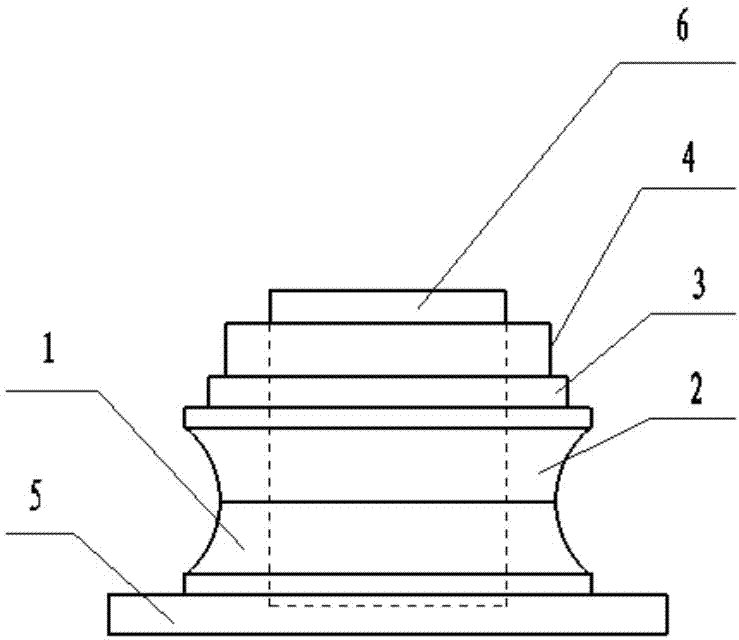

[0016] combine figure 1 , the positioning correction method of the present invention to improve the coaxiality of the inner ring of the two-petal bearing after bonding is to apply glue on the butt joint end faces of the marked A-lobe inner ring 1 and B-lobe inner ring 2 according to the setting direction of the raceway, and then The A-lobe inner ring 1 and the B-lobe inner ring 2 are set on the mandrel 6. If the A-lobe inner ring 1 is in contact with the base 5, a pressure sleeve 3 is placed on the upper surface of the B-lobe inner ring 2, and then fastened by a nut 4. Press the sleeve 3 to bond the inner ring 1 of the A flap and the inner ring 2 of the B flap. After bonding for 2 to 3 seconds, loosen the nut 4 to take off the bonded inner ring of the two petals. At this time, the bonded two petals The outer diameter of the inner ring does not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com