Microsphere logging instrument sidewall contact device

A logging tool and pusher technology, which is used in surveying, wellbore/well components, and earth-moving drilling and mining, etc., can solve the problems that the microsphere and microsphere cannot be detected at the head, the electrode plate cannot be close to the well wall, and the opening and so on. , to achieve the effect of ensuring full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

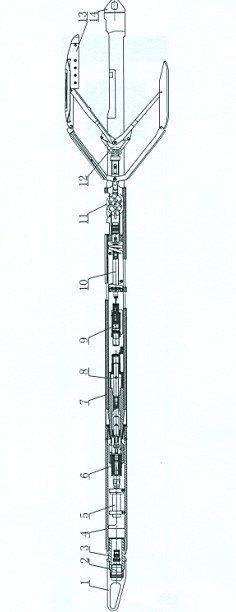

[0021] according to Figure 1-6 The present invention is described in detail. The invention belongs to the main component of the polar plate type current focusing logging instrument, and provides a reliable mechanical pushing guarantee for the microsphere logging instrument that simultaneously measures the resistivity Rx0 and the two curves of the borehole diameter of the underlying flushing zone, and has autonomy. Innovative products.

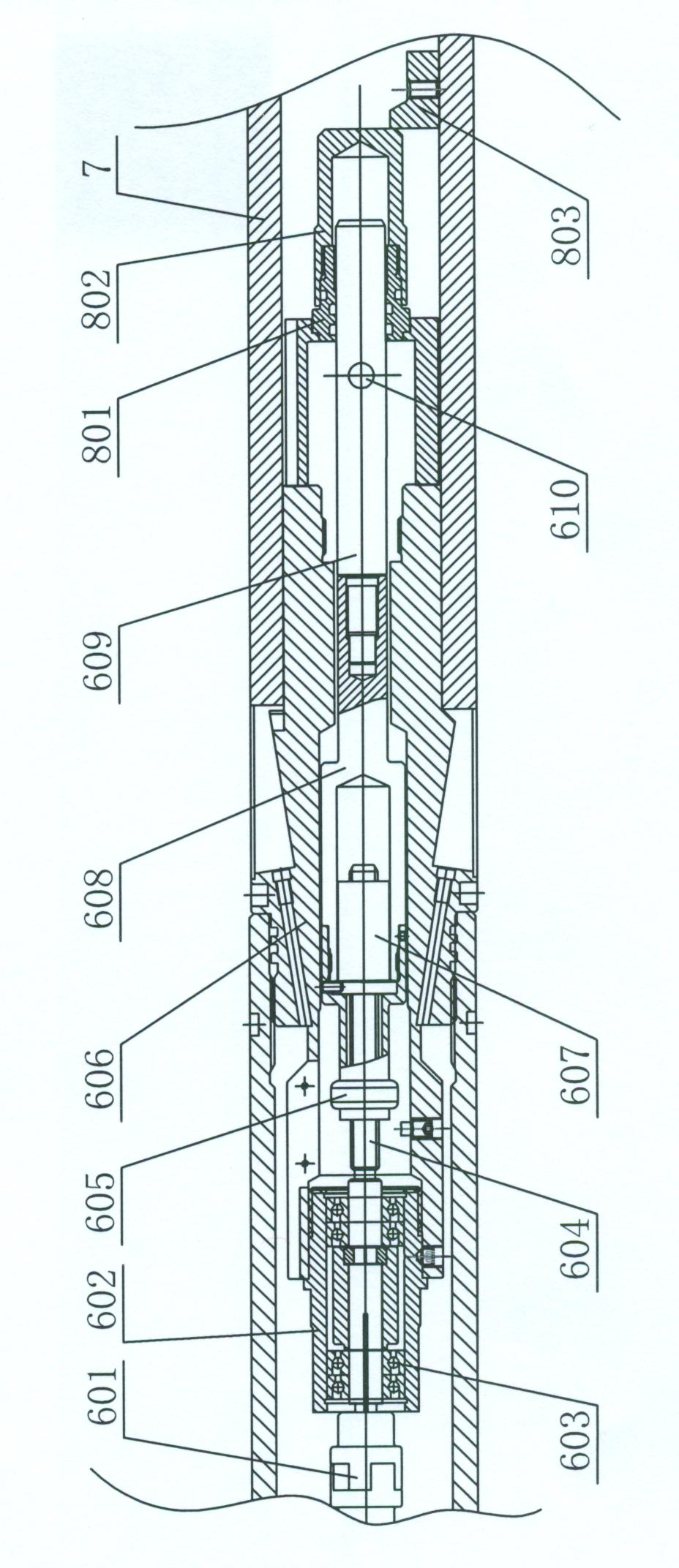

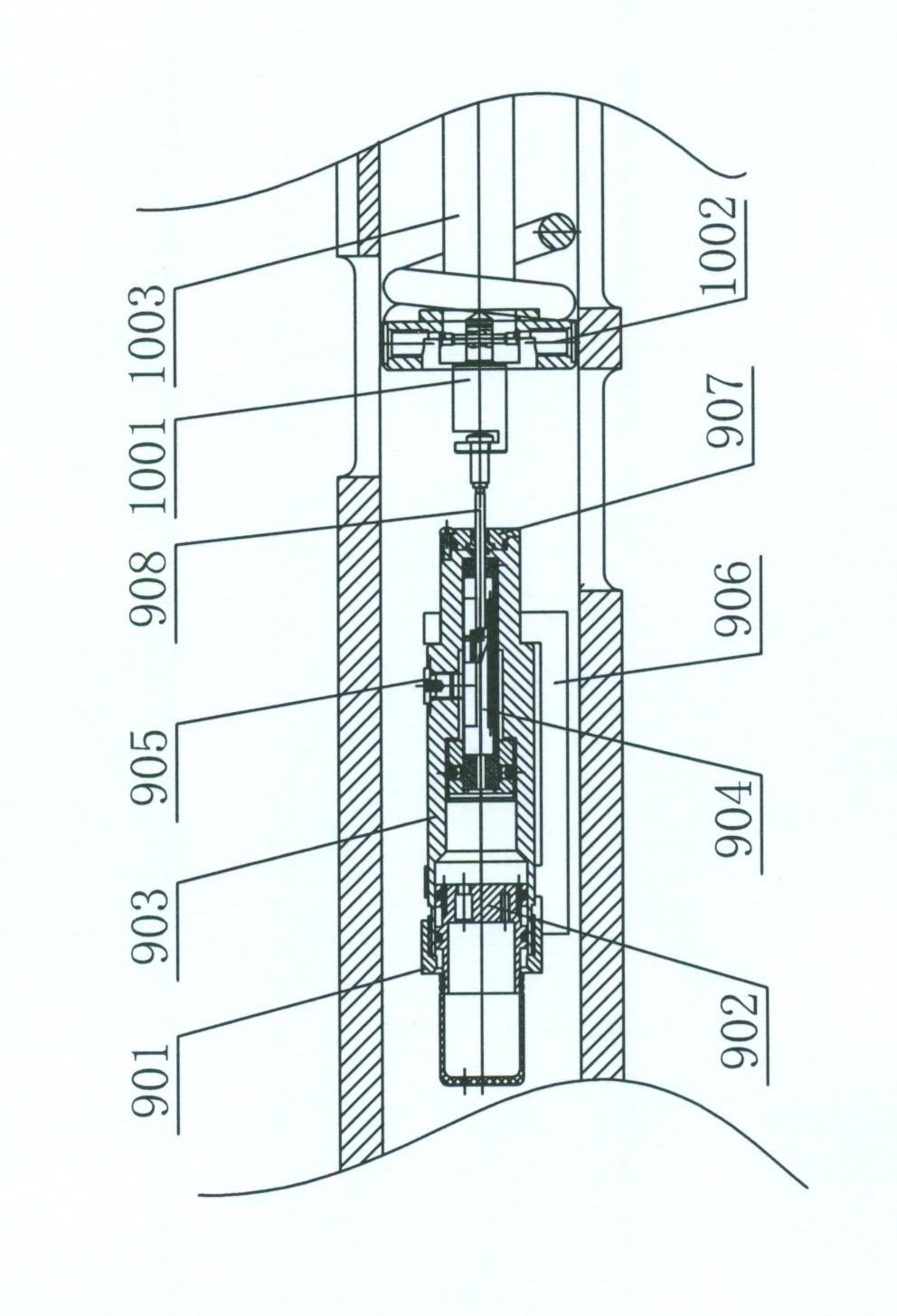

[0022] Such as figure 1 As shown, the present invention is mainly composed of a housing, a motor assembled in the housing in turn, a transmission assembly, a pressure balance assembly, a borehole potentiometer assembly, a spring assembly, a hinge assembly, and a pusher connected to the hinge assembly. Terminals, protective caps at both ends of the shell, lower plugs, etc. Wherein, the shell is an upper shell and a lower shell, and the upper shell and the lower shell are connected by an intermediate joint. An upper joint 3 is connected bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com