Silt solidification processor

A treatment machine and sludge technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of low work production efficiency, large floor area, poor mobility, etc., achieve improved work efficiency, small floor space, prevent Effects of clogging and damaging equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

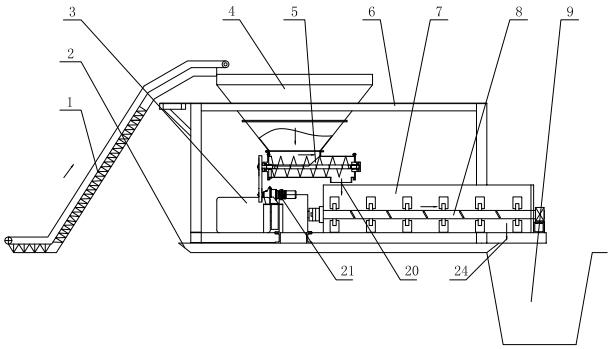

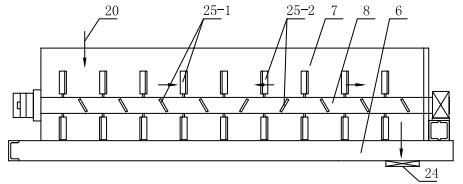

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0020] like figure 1 , figure 2 As shown, the present invention is provided with a stirring chamber 7 at the bottom of the frame 6, and the inside of the stirring chamber 7 is provided with two relatively rotating spiral stirring shafts 8 (see image 3 and Figure 4 ), the stirring shaft 8 is driven to rotate by the main motor 3 through the pulley 10, and there are two feeding ports above the initial section of the mixing chamber 7, one is the sludge feeding port 20, and the other is the curing agent feeding port 22. like figure 1 As shown, the sludge with higher water content is transported to the sludge hopper 4 on the upper part of the frame 6 through the sludge conveyor belt 1, and the bottom of the sludge hopper 4 is provided with a sludge conveying screw shaft 5, which is driven by a motor 21. The end is provided with a sludge f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com