Heavy duty stacker for containers

A stacker and container technology, applied in the field of stackers, can solve the problems of affecting the efficiency of container access, damage to the transportation time of goods, affecting the efficiency of goods, etc., and achieve flexible and convenient use, avoid vibration and tilt, and the overall structure is stable. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

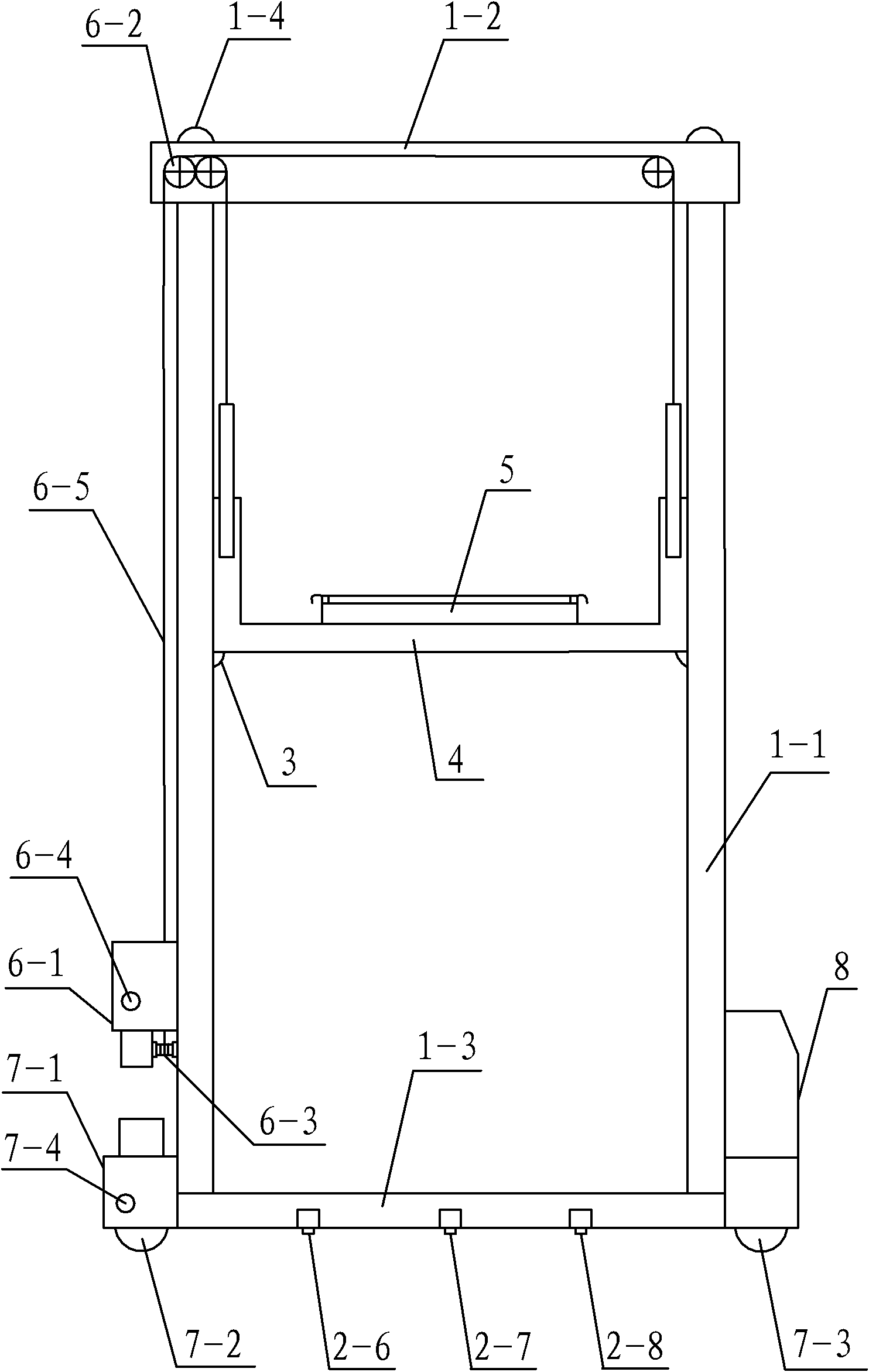

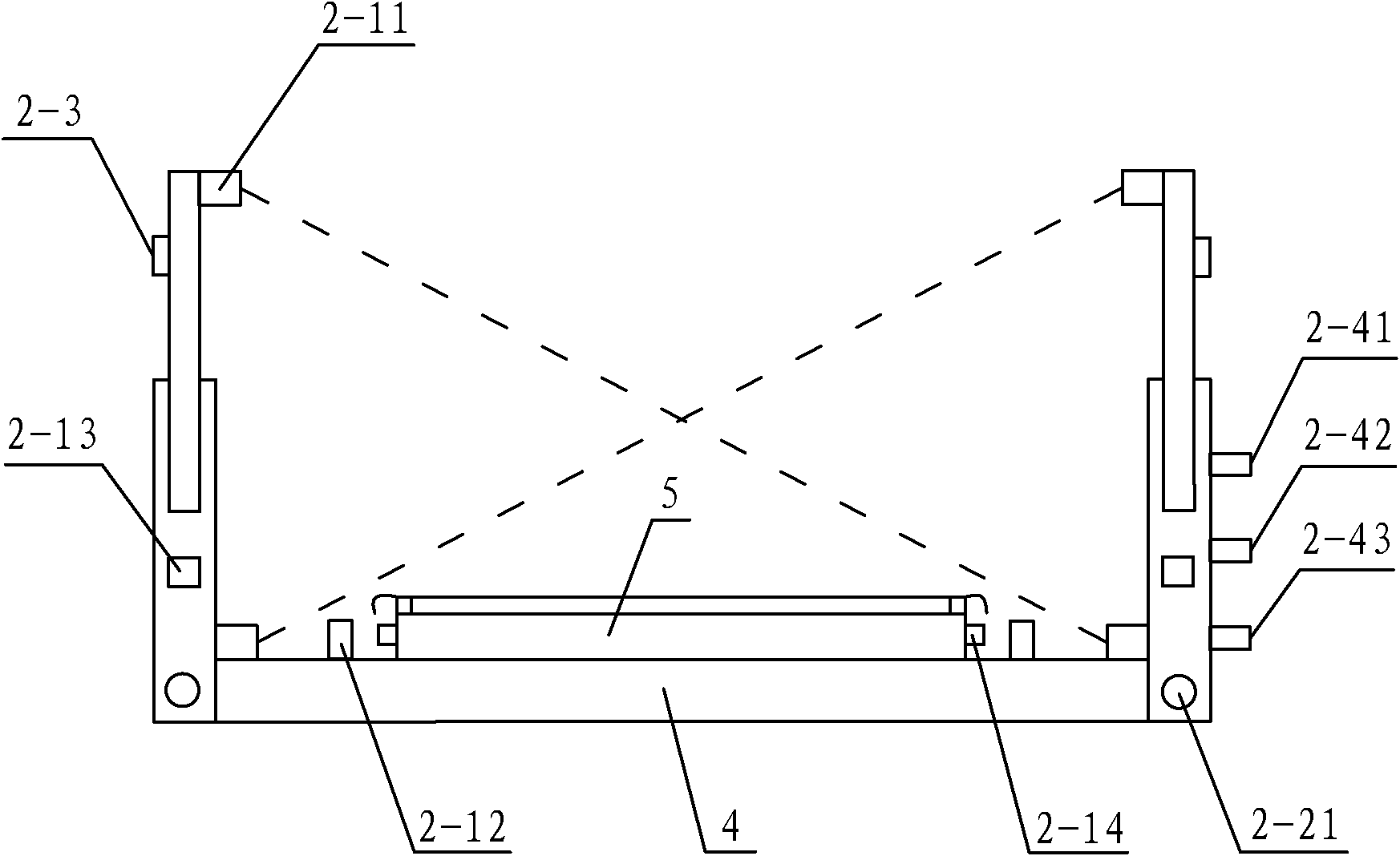

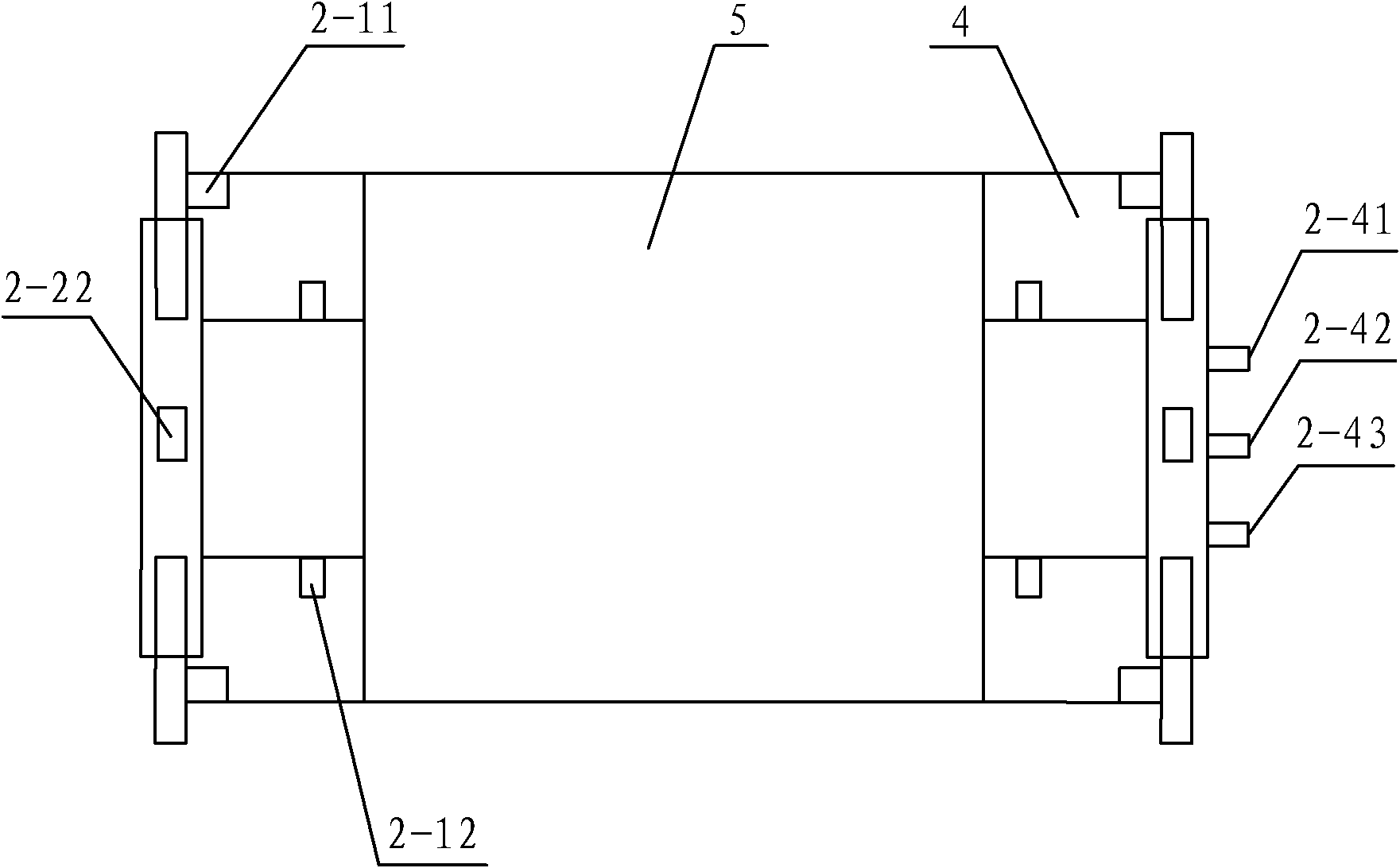

[0044] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a stacker frame and a safety protection device. The inside of the stacker frame is equipped with a cargo platform 4 through a wear-resistant guide rail and a wear-resistant guide wheel 3 matched with the wear-resistant guide rail. The loading platform 4 is provided with a container hooking device 5, and the stacker frame is provided with a lifting device for lifting the loading platform 4, a driving device for driving the operation of the stacker, and a driving device for controlling stacking. The electrical control device 8 for machine work, the electrical control device 8 is respectively connected with the container hooking device 5, the lifting device and the running drive device and controls the work of the container hooking device 5, the lifting device and the running drive device, so The stacker frame is composed of four columns 1-1, an upper beam 1-2 installed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com