Holding strip structure of plastic folder

A file folder and clamping strip technology, which is applied in folders, printing, binding, etc., can solve the problems that the folder pages cannot be clamped together, the clip strips are sharp and right-angled, and the plastic folder pages are difficult to achieve. Wide range of applications, great social benefits, and improved binding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

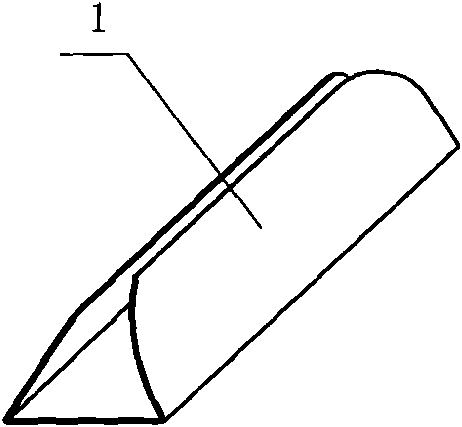

[0025] A clip structure for a plastic file folder, which consists of a triangular long plastic clip 1 with a cross-section that opens upward and forms a small gap. The two sides of the triangle are viewed from the side, and the two ends along the length The upper part is arc-shaped, and the arc is 90 degrees. The circular arc method is adopted, and the plastic folder page 2 is inserted smoothly and smoothly, and the appearance is beautiful.

Embodiment 2

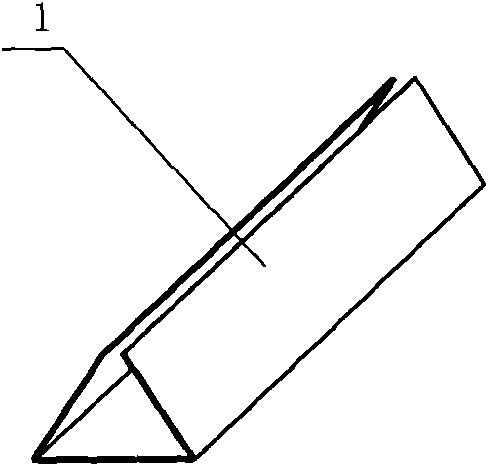

[0027] A clip structure for a plastic file folder, which consists of a triangular long plastic clip 1 with a cross-section that opens upward and forms a small gap. The two sides of the triangle are viewed from the side, and the two ends along the length The top is a hypotenuse, and the included angle of the hypotenuse is 45 degrees. Adopting the hypotenuse structure, the processing is easier.

[0028] The present invention seems to be a simple and minor improvement, but it involves a wide range of applications, and the cumulative social benefits are very large, which greatly improves the binding speed, quality and work efficiency, and speeds up the activities of using such folders. process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com