Method for processing rectangular round-hole wire copper pipe of dual water internal cooling generator

A double-water internal cooling and processing method technology, applied in the field of copper processing, can solve the problems of shortened service life of the unit, poor cooling effect of the coil, low dimensional accuracy of the finished product, etc., and achieve the advantages of extended life, improved working conditions and reduced volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A specific embodiment of the present invention, the specific embodiment of stretching the tube blank comprises the following steps:

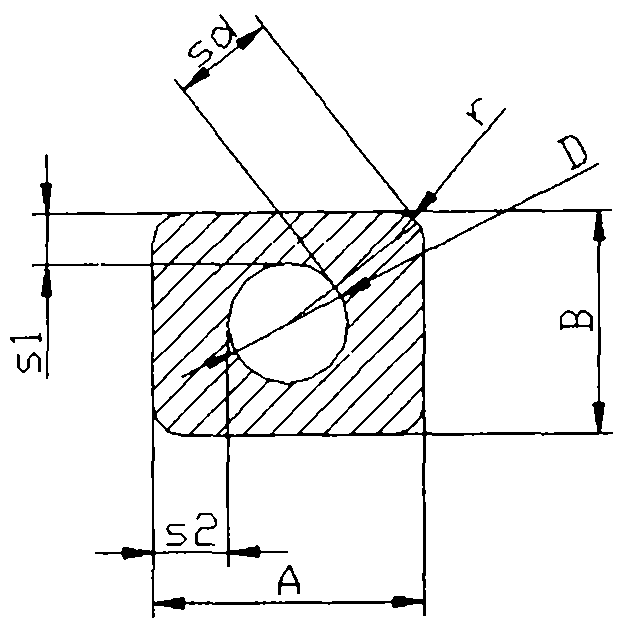

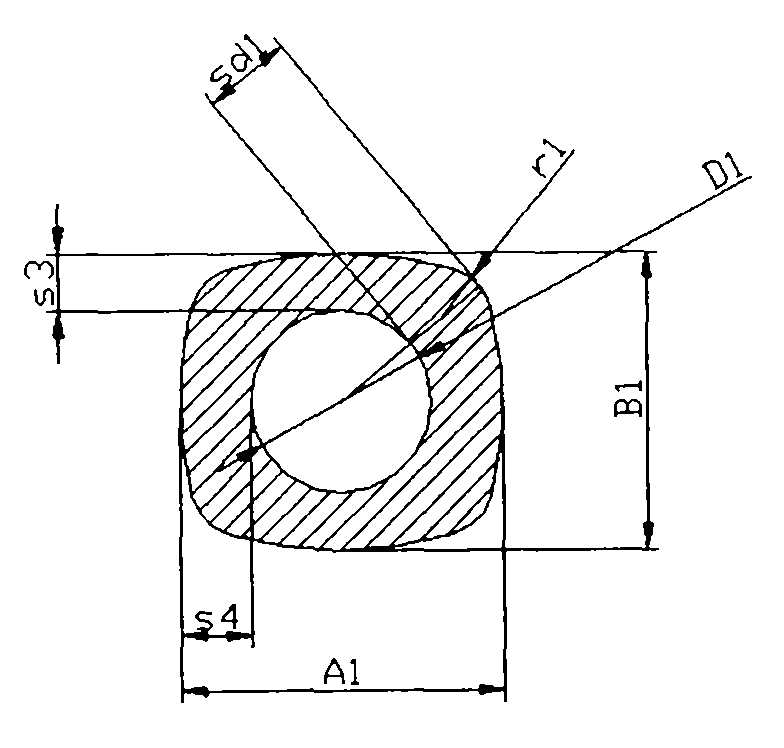

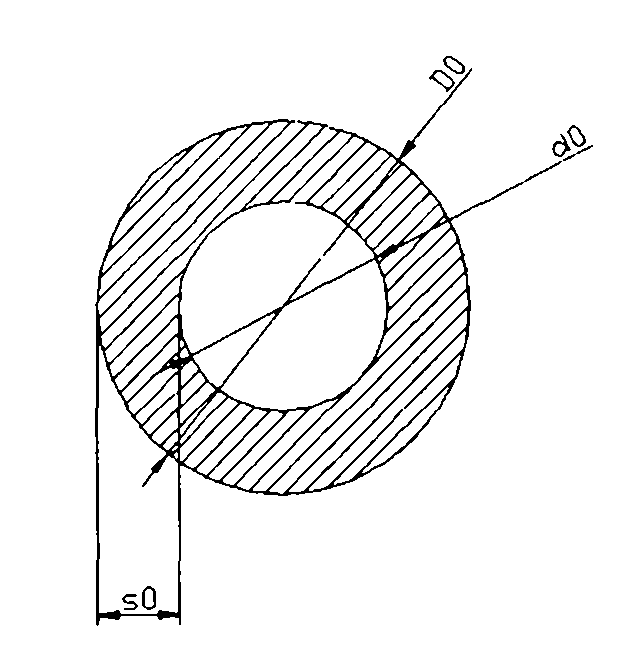

[0037] Step 1, select the tube blank; when selecting the tube blank, first determine the wall thickness dimension of the wire conduit tube blank according to the maximum wall thickness value on the cross-sectional diagonal of the selected tube blank, and the wall thickness dimension of the wire conduit tube blank is 1.05-1.25 times the wall thickness of the corner line; secondly, determine the size parameters of the movable inner mold according to the stretching conditions of the movable mold; thirdly, calculate the round hole size of the intermediate transition product according to the inner hole size of the product; thirdly, according to the determined circle The hole size and the wall thickness on both sides of the length and width of the product are combined with the processing deformation rate to determine the wall thickness of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com