Device for handling powder for a welding appatarus

A technology of welding device and powder conveying device, which is applied in welding equipment, arc welding equipment, and shielding removal devices, etc., can solve the problems of high cost, complex structure, troublesome installation and operation, etc., and achieve the effect of powder treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, preferred embodiments of the present invention will be introduced with reference to the accompanying drawings.

[0022] In the following description of preferred embodiments of the present invention, the same reference numerals will be used for similar components in different drawings.

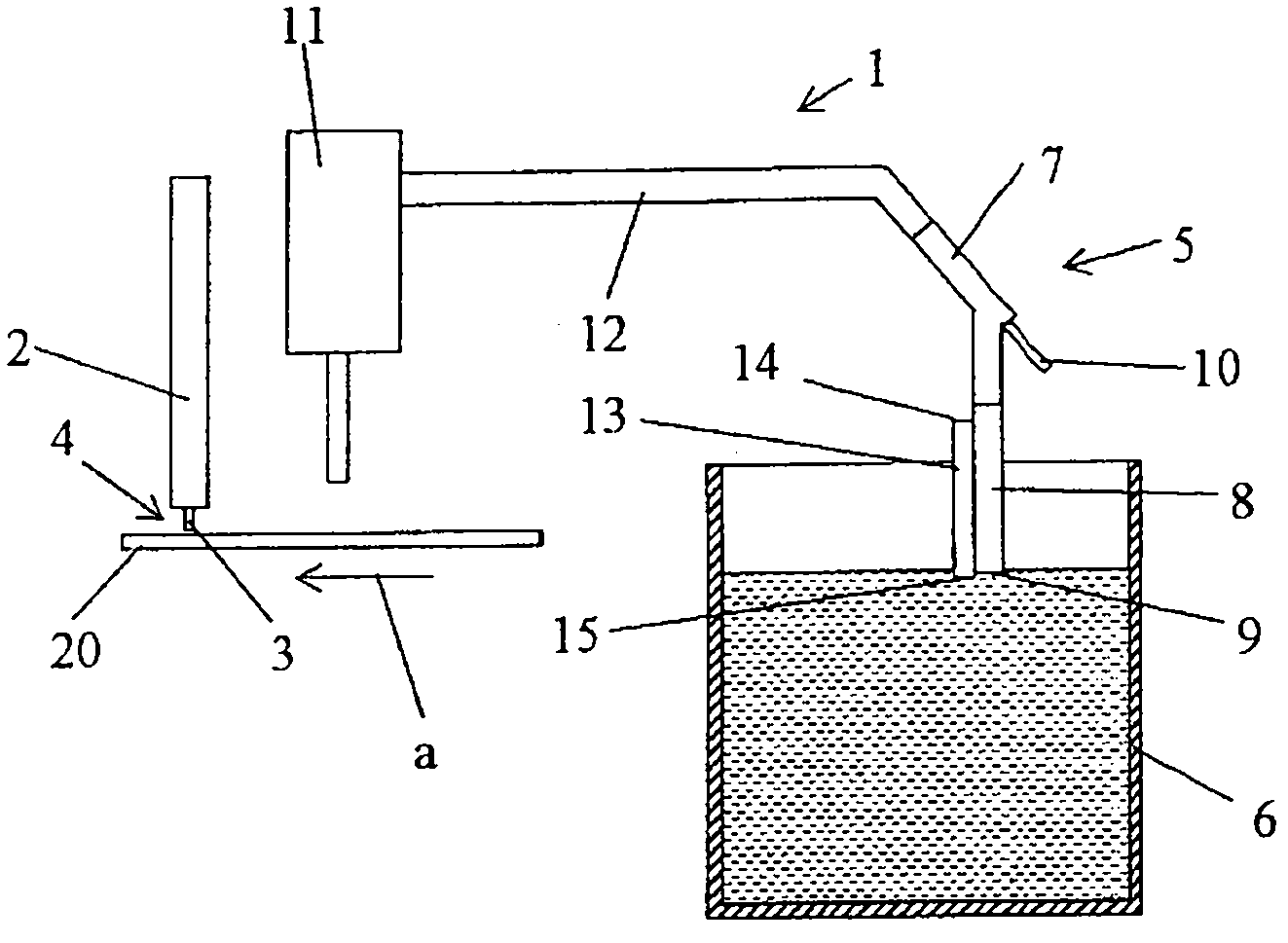

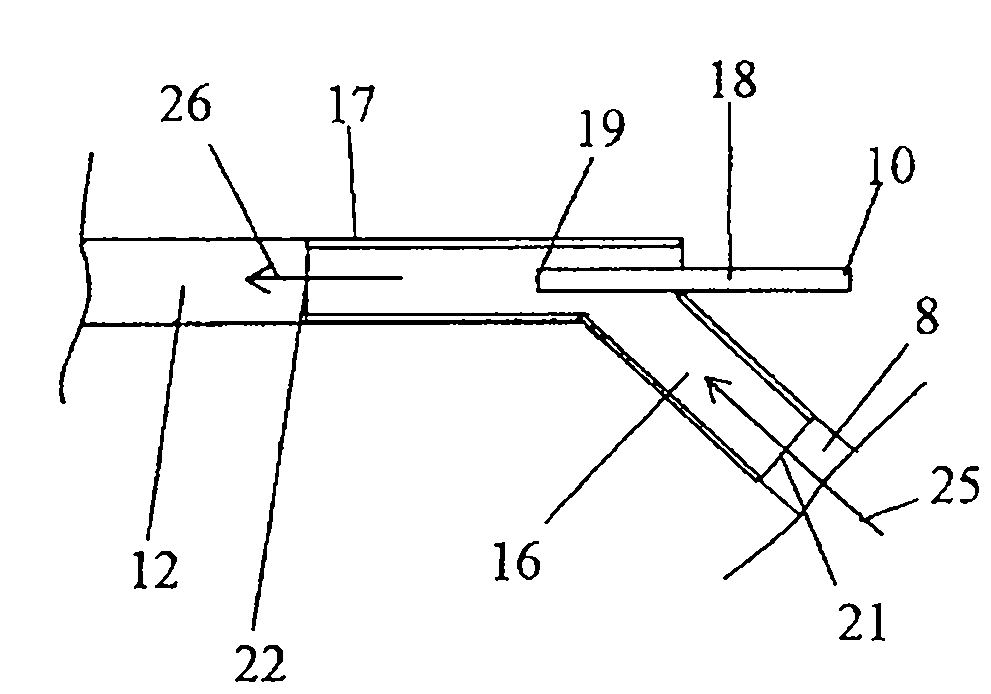

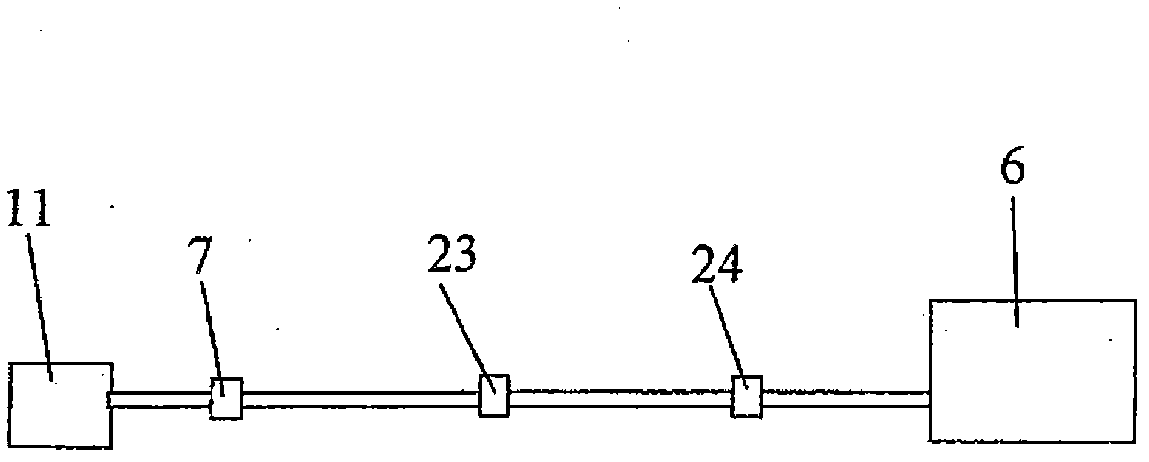

[0023] figure 1 It is a schematic diagram of a welding device 1 for powder welding according to an embodiment of the present invention. The welding device 1 includes a welding head 2 for feeding at least one welding electrode 3 onto a welding area 4 of a workpiece 20 ; The powder delivery device 5 comprises an injector 7 and a first tube 8, the first end of which has an opening 9 which is arranged in the container and is used to deliver powder from the container 6; the second end of the first tube 8 is connected to to injector 7. The powder delivery device also includes a drop container 11 and a second pipe 12 arranged between the injector 7 and the drop container 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com