Stator assembly for an electric motor

A stator structure and stator slot technology, applied in structural connection, magnetic circuit shape/style/structure, electromechanical devices, etc., can solve the problems of position uncertainty temperature controller and winding, high manufacturing cost, aggravated interference, etc., to achieve reliable Cut off, improve safety, heat detection reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

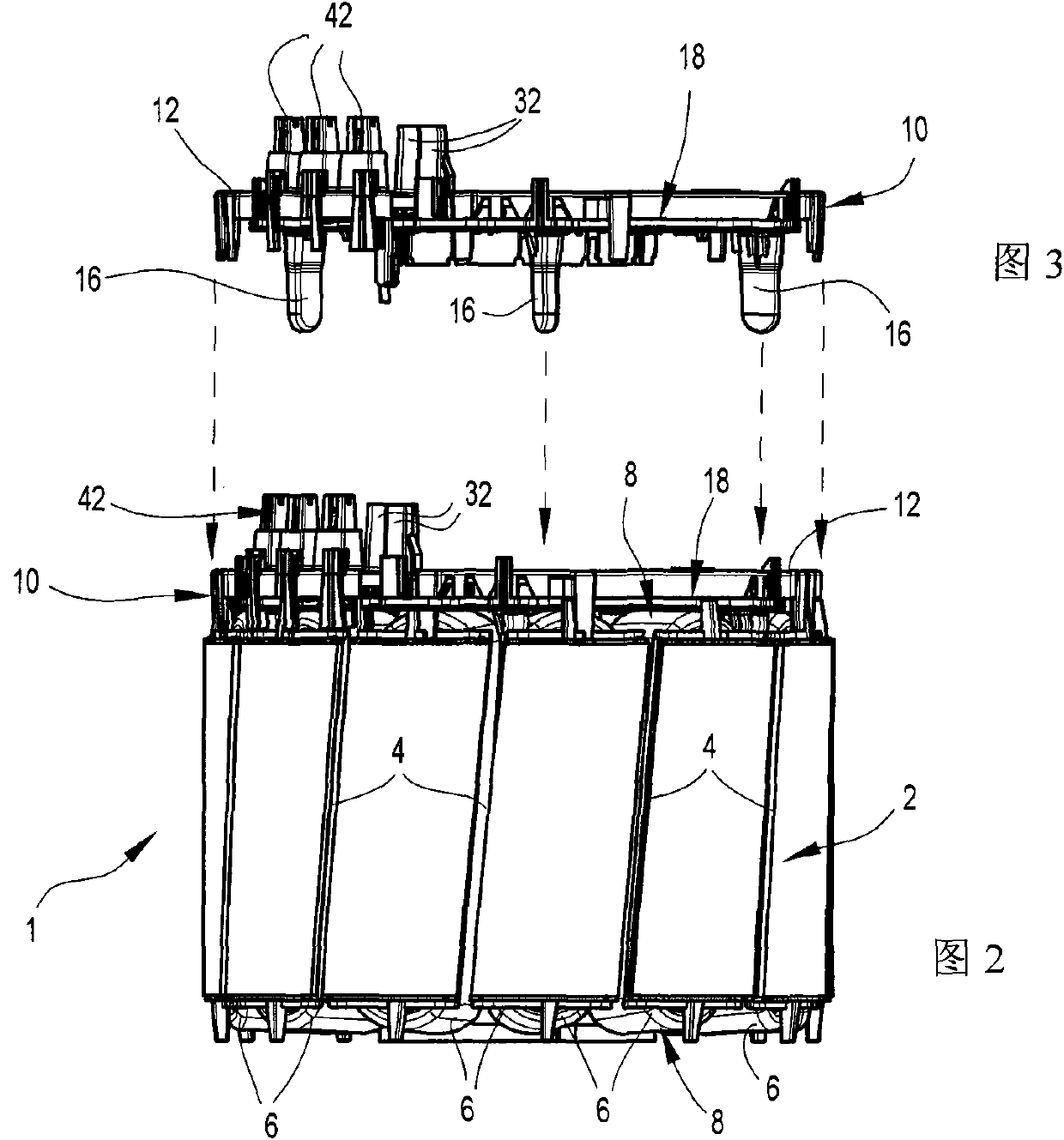

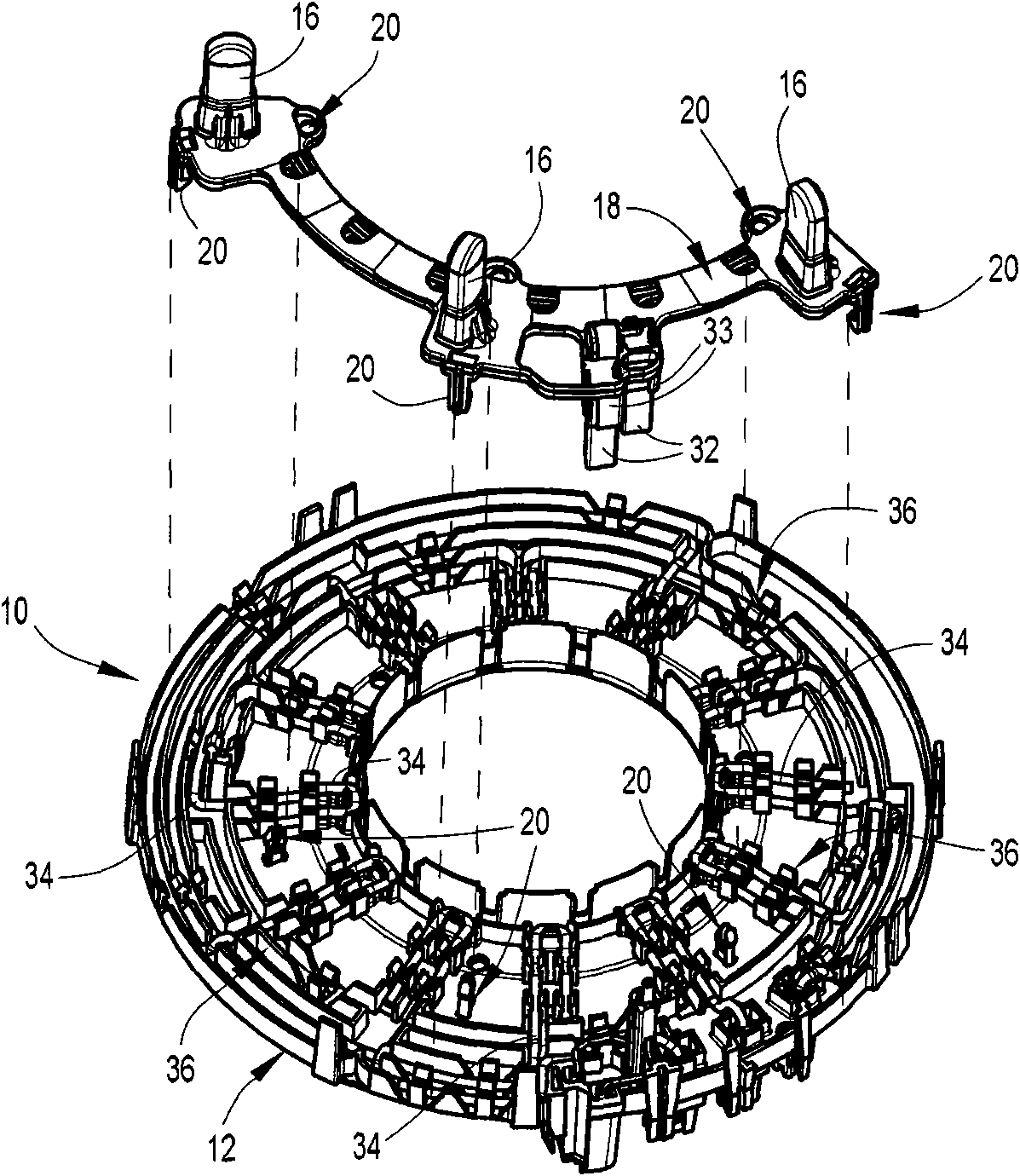

[0022] In the different figures of the drawings, the same parts are always provided with the same reference signs, so that if the components have been described once before, the relevant descriptions also apply similarly to the other figures of the figures, Corresponding parts with corresponding reference numerals are thus likewise recognizable in these figures.

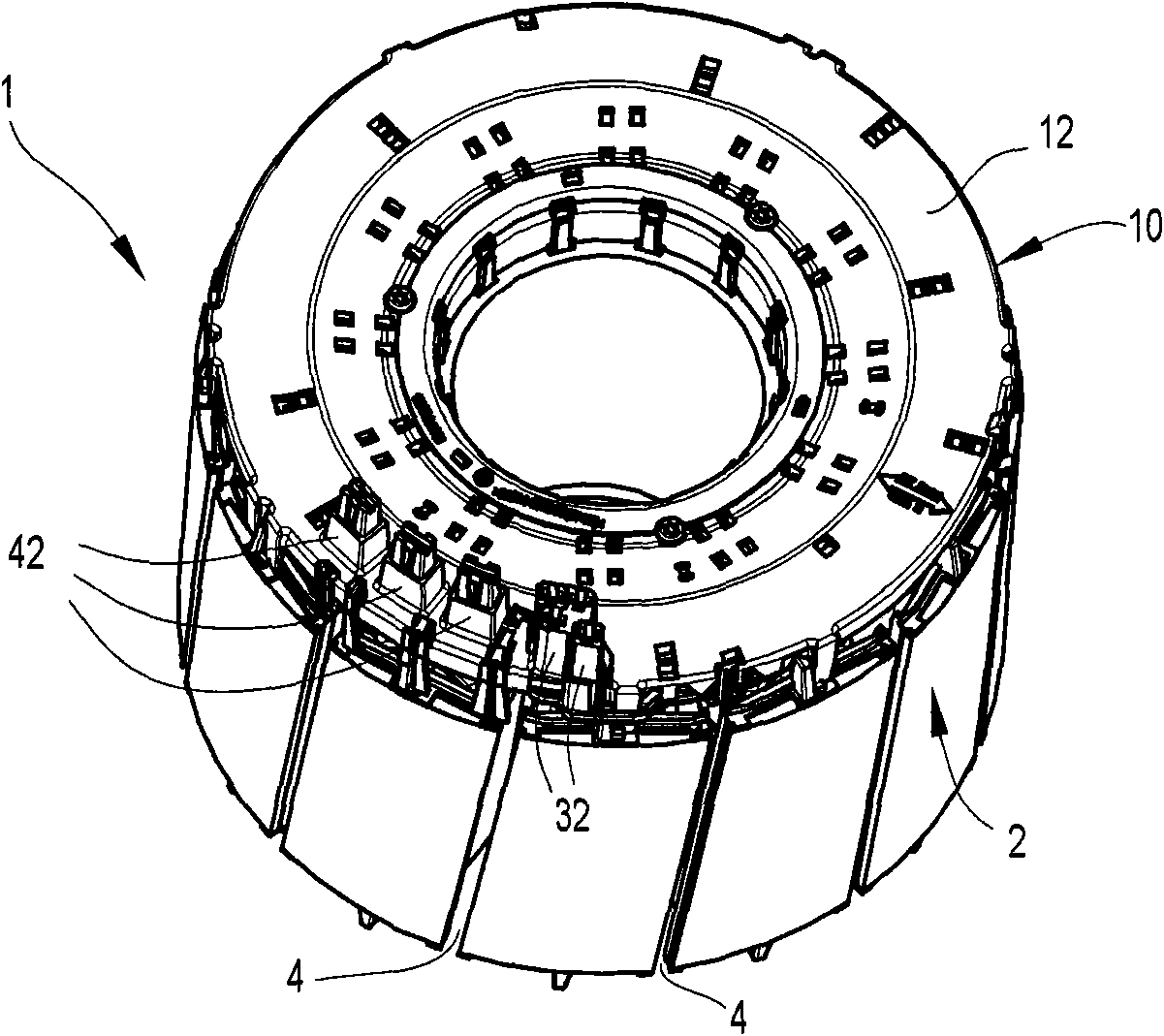

[0023] The stator structure 1 according to the invention essentially comprises a stator lamination 2 with a stator winding 6 extending through a stator slot 4 . Outside the stator slots 4 , the stator windings 6 each extend from slot to slot in the area of the end faces of the stator laminations 2 and form so-called winding ends 8 on each end face. Furthermore, the stator structure 1 has an interconnection device 10 for electrically connecting the stator windings 6 with each other and with supply lines (not shown). The switching device 10 essentially comprises a circular or annular switchboard 12 lying in a plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com