Lubrication system for feeding lubricant in type of air pressure

A lubrication system, pneumatic technology, applied in the direction of engine lubrication, engine components, mechanical equipment, etc., can solve the problems of upright grease tank, difficult spring reset, secondary pollution of grease, etc., to avoid pollution and manufacturing costs. Low, compact design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

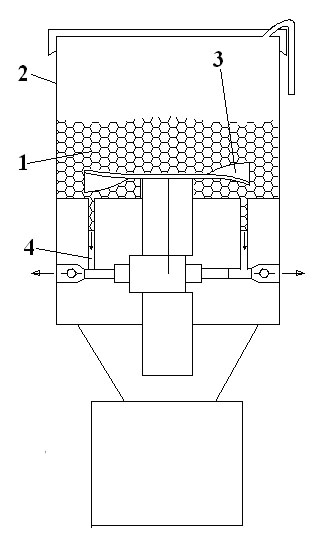

[0027] Embodiment 1, the grease outflow device 4 communicates with the soft grease bag 3, the soft grease bag 3 is located in the grease tank 2, the air compression pump 5 is connected to the grease tank 2, the inner wall of the grease tank 2 is connected to the soft grease bag The air cavity 6 between 3 communicates with the air compression pump 5, which is a closed compressed air cavity 6.

[0028] The grease tank 2 is made of toughened glass, and is detachably mounted on the base 1 by threading, and the grease tank 2 and the base 1 are connected by a sealing member to form a sealed environment.

[0029] Send air to the compressed air cavity 6 through the air compression pump 5, keep the air pressure in the compressed air cavity 6 stable at 3bar, press the soft grease bag 3 through the air pressure, and make the grease in the grease bag flow to the grease outflow device 4. Carry out fat feeding work.

Embodiment 2

[0030] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the grease tank 2 is made of stainless steel and is fixedly connected to the base 1 by bolts.

[0031] Send air to the compressed air cavity 6 through the air compression pump 5, keep the air pressure in the compressed air cavity 6 at 5bar stably, press the soft grease bag 3 through the air pressure, and make the grease in the grease bag flow to the grease outflow device 4. Carry out fat feeding work.

[0032] The above-mentioned lubricating system for pneumatic fat bag feeding has the following advantages compared with the existing system:

[0033] (1) Due to the use of soft grease bags, the problem of grease contamination is avoided;

[0034] (2) Fat feeding can always be performed at a constant pressure;

[0035] (3) When installing the soft grease bag, there is no need to work hard to overcome the elastic force of the spring;

[0036] (4) The system can be installed tilted or even upsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com