Valve rod sealing structure capable of being maintained with voltage

A technology of sealing structure and valve stem, which is applied in the direction of shaft seal, sliding valve, valve details, etc., can solve the problems of heavy maintenance workload, inability to replace packing, and increased operating torque, so as to quickly eliminate leakage and facilitate the replacement of seals Circle operation, reduce the effect of valve operating torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

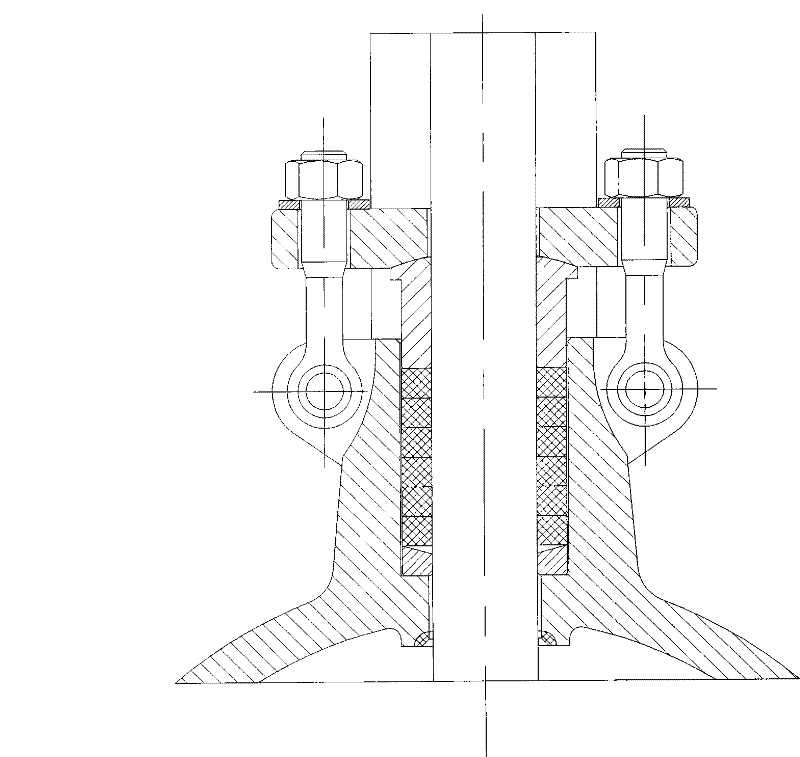

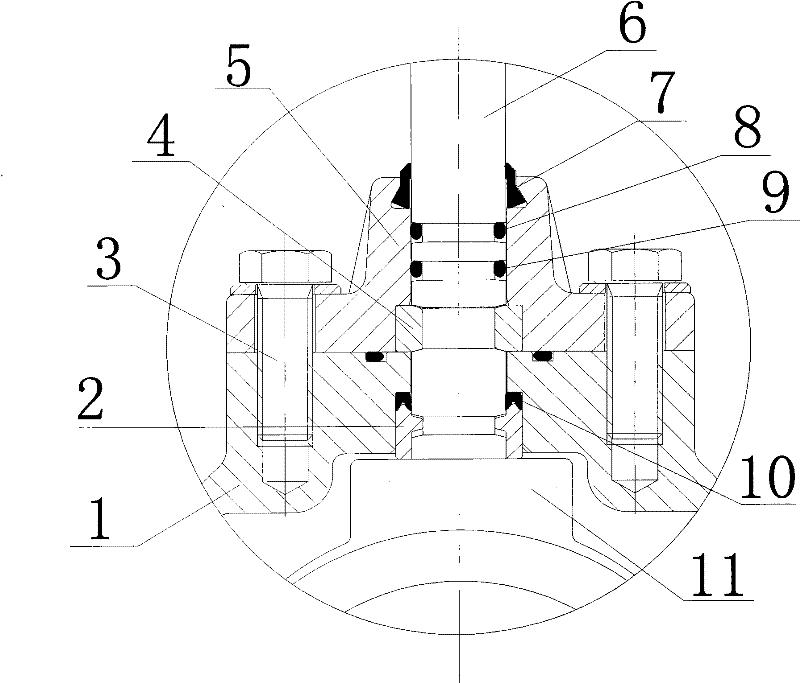

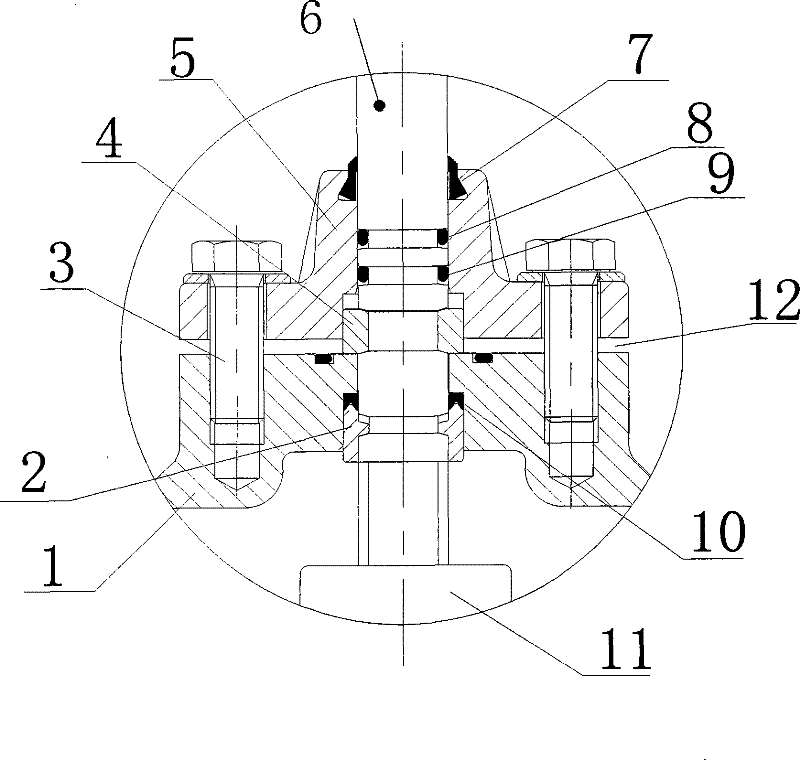

[0019] like figure 2 As shown, a valve stem sealing structure that can be maintained under pressure, the structure includes a valve cover 1, a gland 5, a valve stem 6, a dust retaining ring 7, a first sealing ring 8, a second sealing ring 9, a third sealing ring Circle 10, flashboard 11. The gland 5 holds the dust shield ring 7 , the first sealing ring 8 , the second sealing ring 9 , the snap ring 4 and the valve stem 6 , and is fixed on the valve cover 1 by bolts 3 . The dust retaining ring 7 is arranged on the top between the valve stem 6 and the gland 5 . The first sealing ring 8 and the second sealing ring 9 are O-shaped rubber sealing rings, forming two seals between the valve stem 6 and the gland 5 . The third sealing ring 10 is a V-shaped rubber sealing ring, which forms an upper seal between the valve stem 6 and the valve cover 1 . The push ring 2 and the snap ring 4 are left and right symmetrical rings cut from the middle, and can be stuck on the valve stem 6 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com