Back cavity-perforated plate-type casing treatment method

A casing processing and perforated plate technology, applied in mechanical equipment, non-variable displacement pumps, machines/engines, etc., can solve the problems of complicated flow in the wall area of the blade tip, blockage of the air flow at the tip, and leakage of the blade tip, and increase the Stable working range, delayed premonitory stall, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

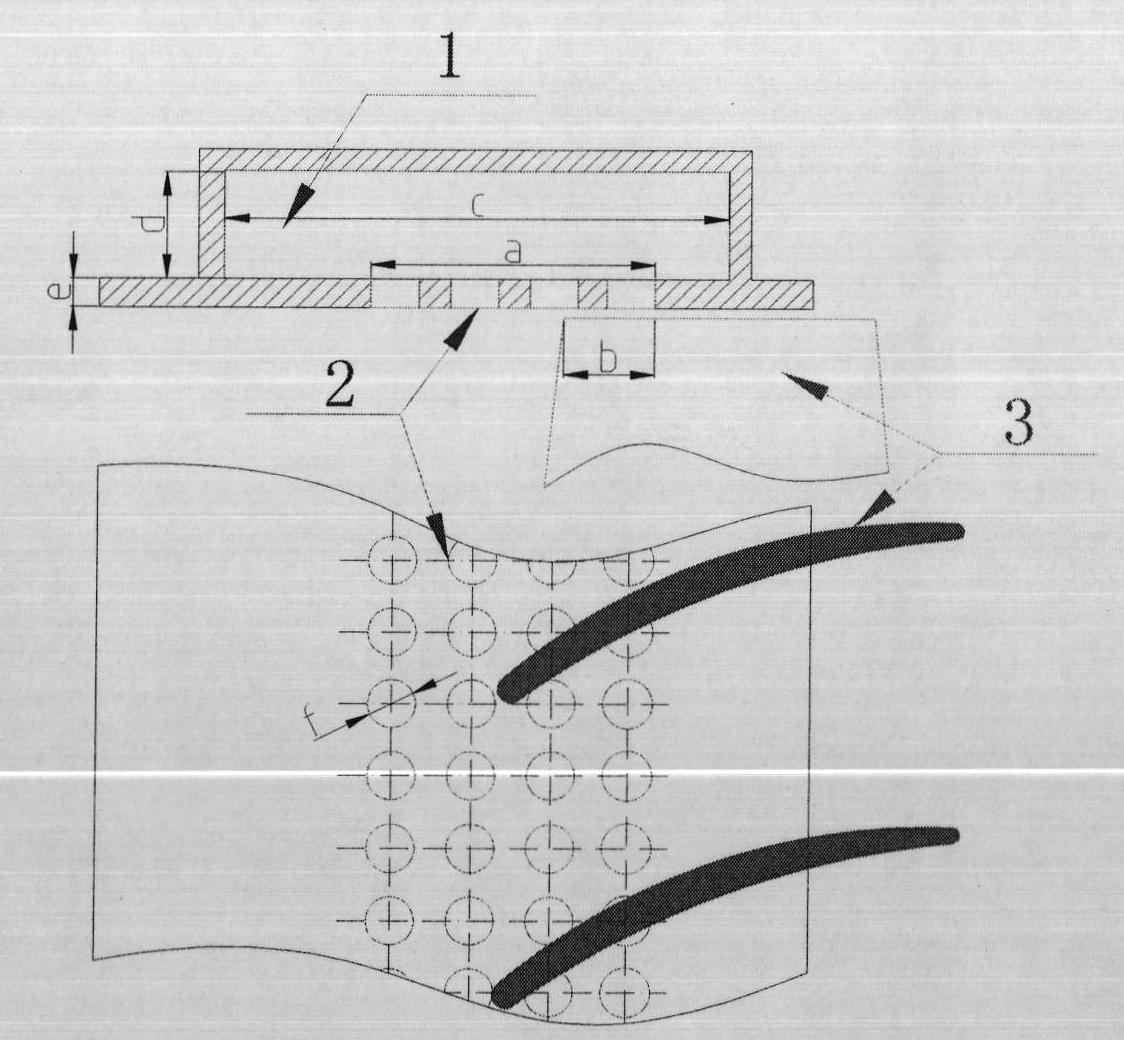

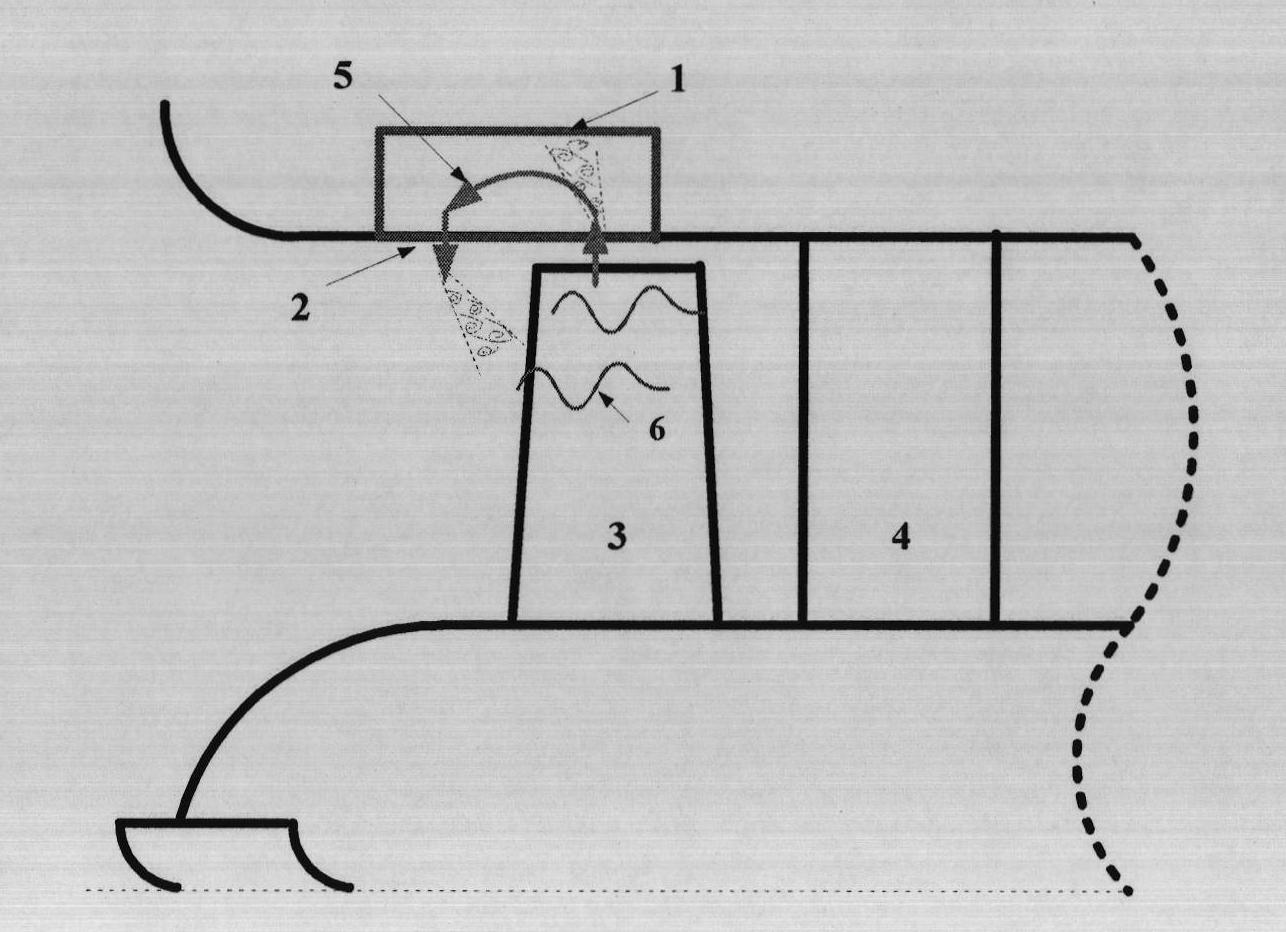

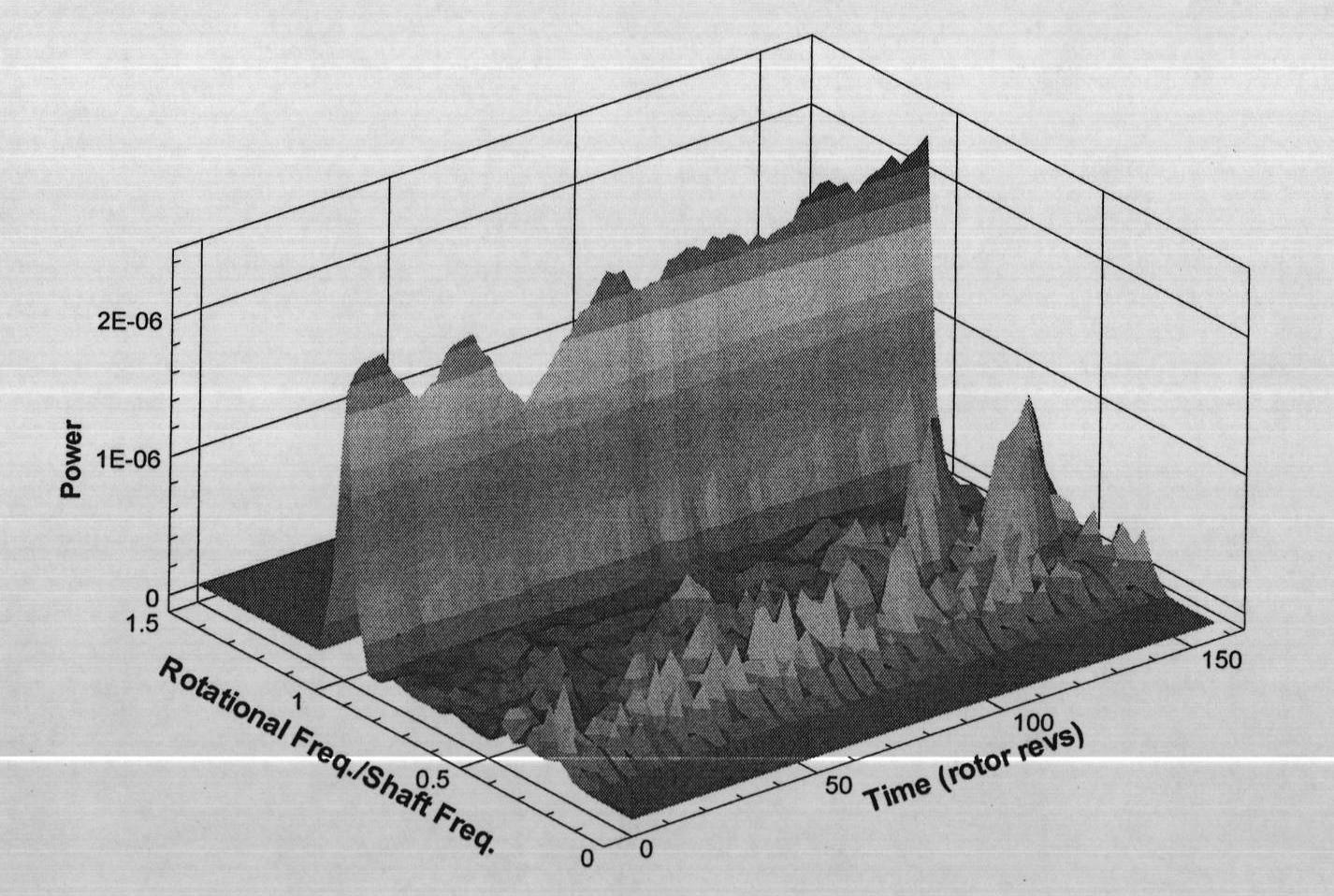

[0020] The cavity-backed perforated plate casing treatment method is to process the cavity-backed perforated plate casing at the leading edge of the compressor rotor to change the boundary conditions of the entire power system to affect its system evolution behavior and achieve the purpose of broadening the stable working range of the compressor. The specific mechanism of action is due to the supercharging effect of the rotor, such as figure 2 As shown, the self-adaptive flow phenomenon 5 that will naturally form in the back cavity 1 is processed in the back cavity perforated plate casing. The inflowing and outflowing airflow will form an unsteady shedding vortex at the edge of the perforated plate 2. When the pressure disturbance wave in the flow field is incident on the unsteady impedance boundary, the wave-vortex interaction mechanism will effectively absorb and dissipate the vortex. Dissipate the energy of the pressure disturbance wave, thereby suppressing the nonlinear a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com