Vertical-shaft wind power generation gearbox

A gearbox and vertical shaft technology, which is applied to wind turbine components, wind engines, gear transmissions, etc., can solve difficult problems such as broken teeth, and achieve the effects of weight reduction, high transmission precision, and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

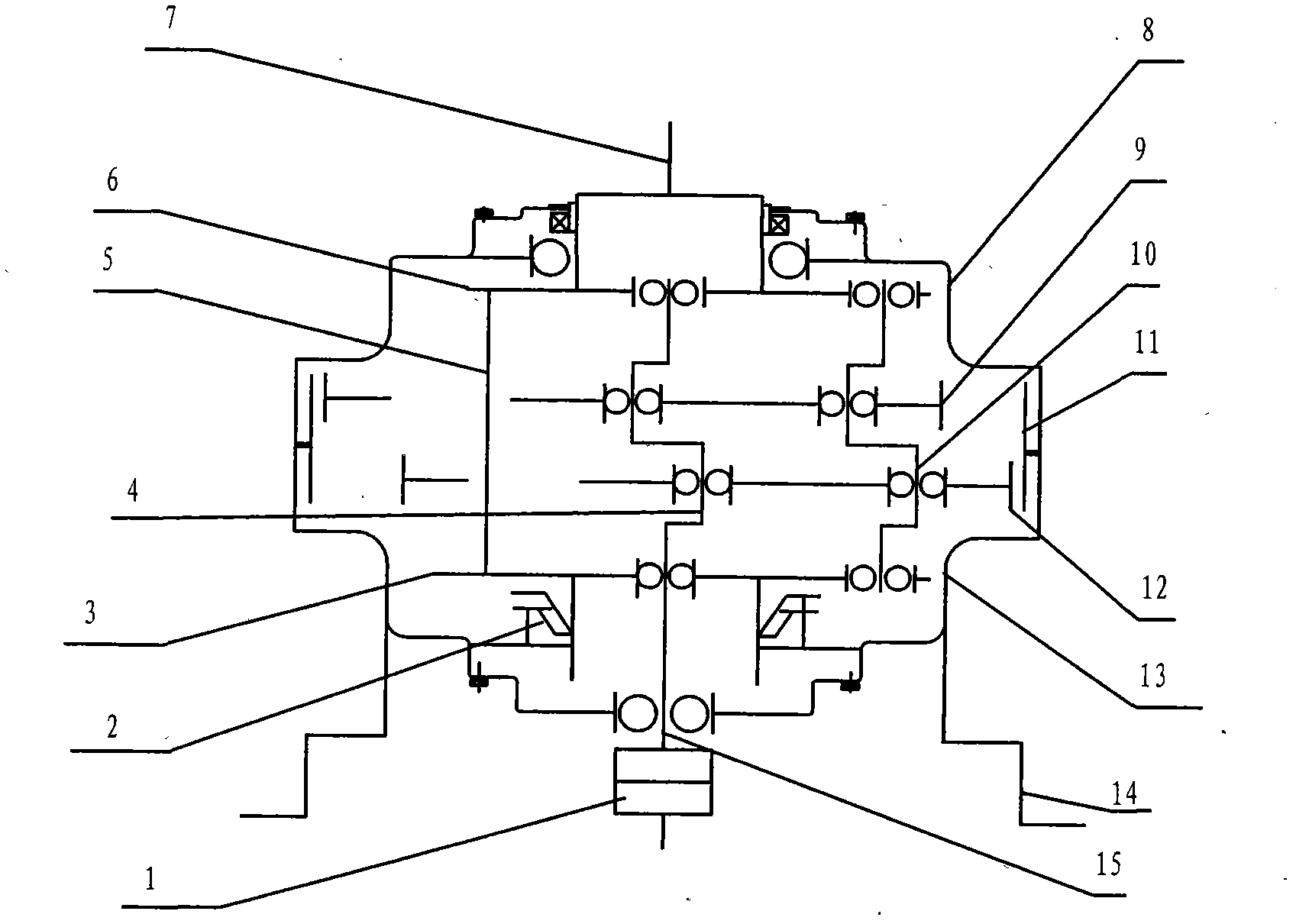

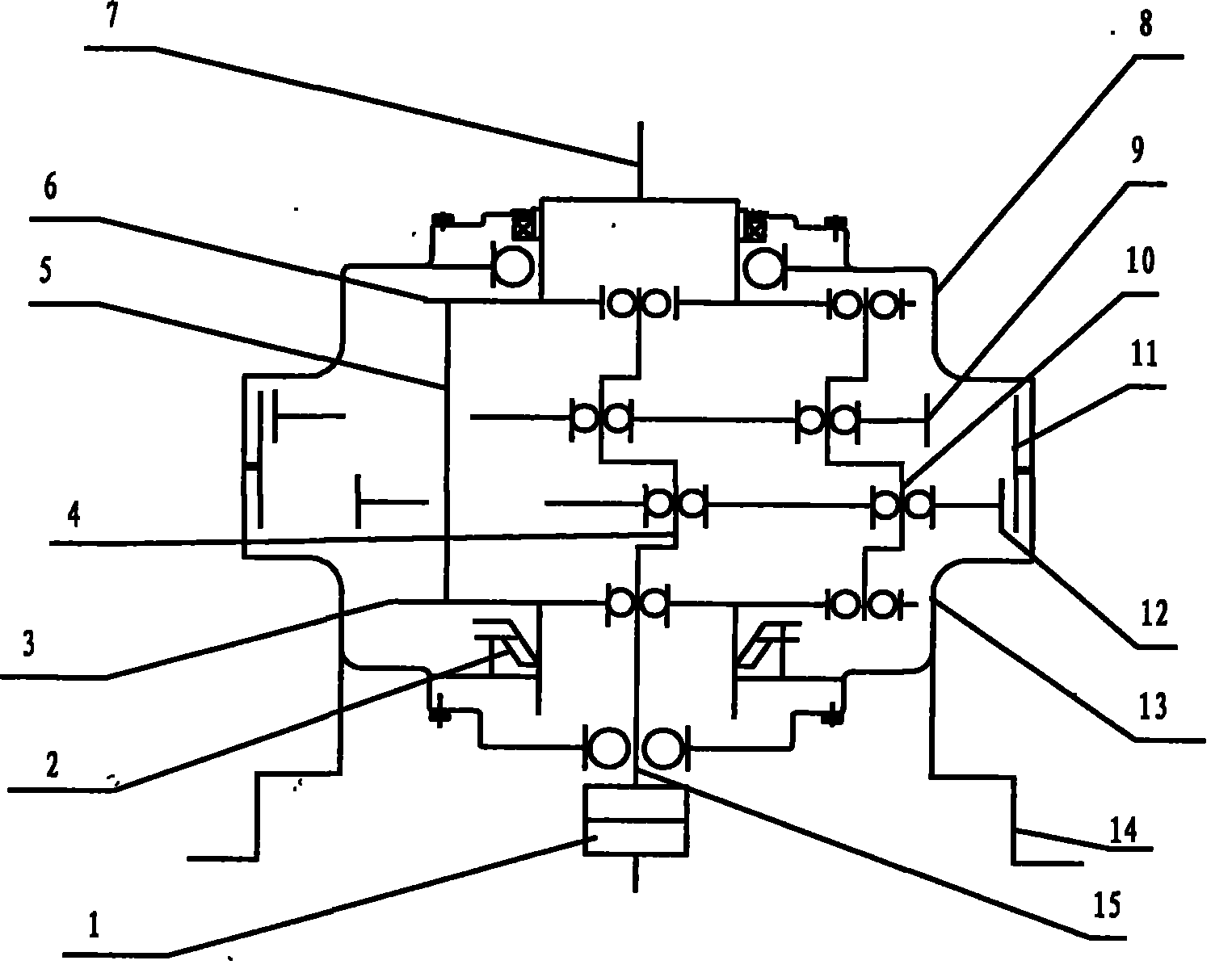

[0011] Example 1: Combining figure 1 , The present invention is a vertical axis wind power generation gearbox, which is composed of a casing and a first-stage speed-up mechanism, and the casing is connected with the first-stage speed-up mechanism.

[0012] The present invention also has the following technical characteristics:

[0013] The casing includes an upper casing (8), a lower casing (13), a support (14), an internal gear (11) and a low-speed shaft (7), and the low-speed shaft (7) is connected to the upper casing (8) , the upper casing (8) connects the lower casing (13) and the internal gear (11), and the lower casing (13) connects the support (14).

[0014] The first-stage speed-up mechanism includes a flexible support device (2), a lower support plate (3), an eccentric bushing (4), a support shaft (5), an upper support plate (6), a first planetary gear (9) , the eccentric crankshaft (10), the second planetary gear (12) and the high-speed shaft (15), the flexible sup...

Embodiment 2

[0015] Example 2: Combining figure 1 , the one-stage speed-up transmission mechanism of the present invention includes upper and lower support plates arranged in the casing, planetary gears with identical dimensions, an internal gear fixed integrally with the casing, and two eccentrically equal and staggered 180° The set eccentric shaft sleeve, the eccentric crankshaft which is equal to the eccentricity of the eccentric shaft sleeve and staggered by 180°, the support shaft which is fastened to the upper and lower support plates, the rolling bearing matching the eccentric sleeve and the planetary gear, and the upper and lower machine The shell, the rolling bearing matched with the upper and lower support plates and the rolling bearing matched with the eccentric crankshaft, the upper and lower support plates, and the planetary gear. The main function of the flexible support device is to bear the axial force and the weight of the rotating parts. Its main purpose is to reduce the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap