Local electroplating device for micro parts

A small parts, partial electroplating technology, applied in the direction of plating tank, electrolysis process, electrolysis components, etc., can solve the problems of inability to realize partial electroplating of small parts, no connection, no suitable space for the plating tank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

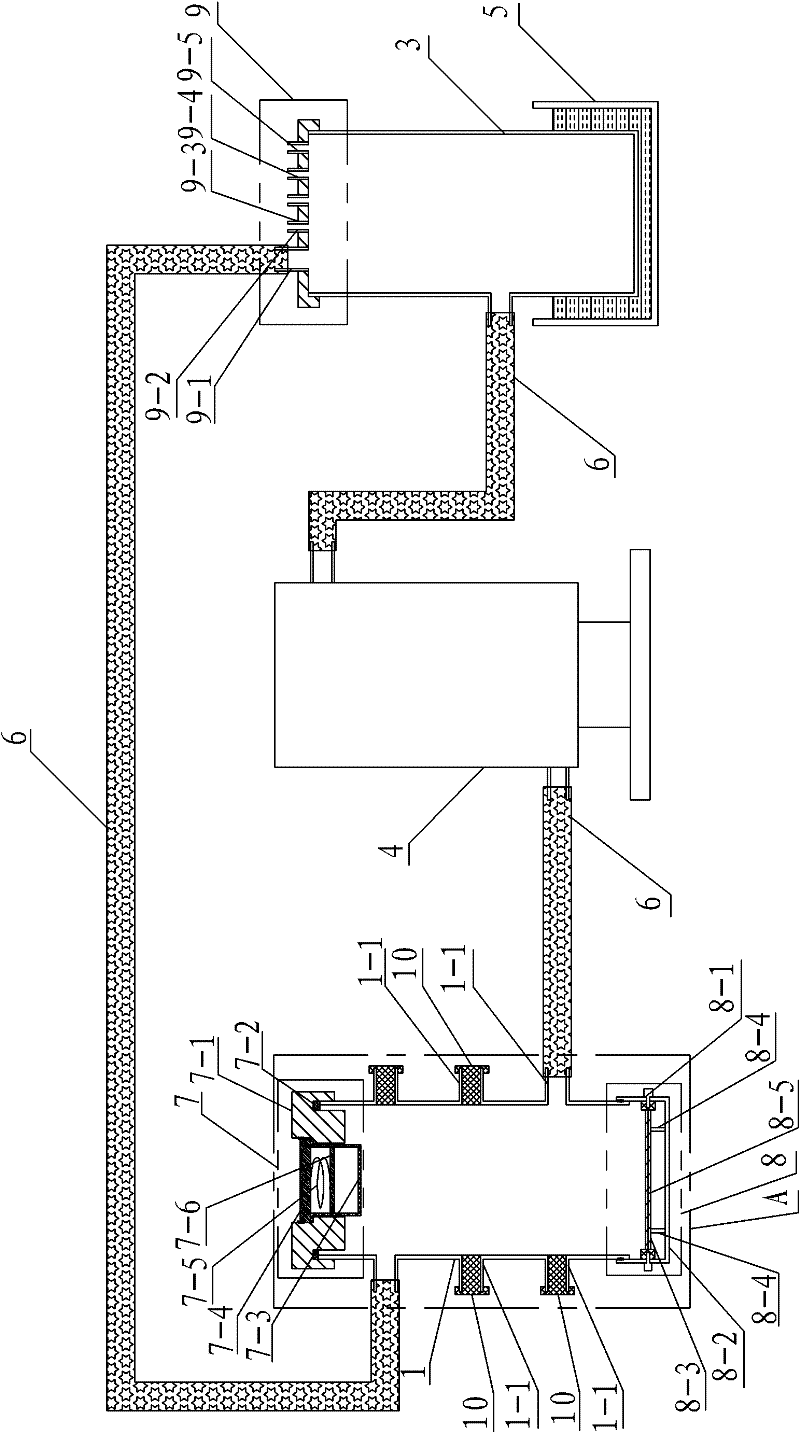

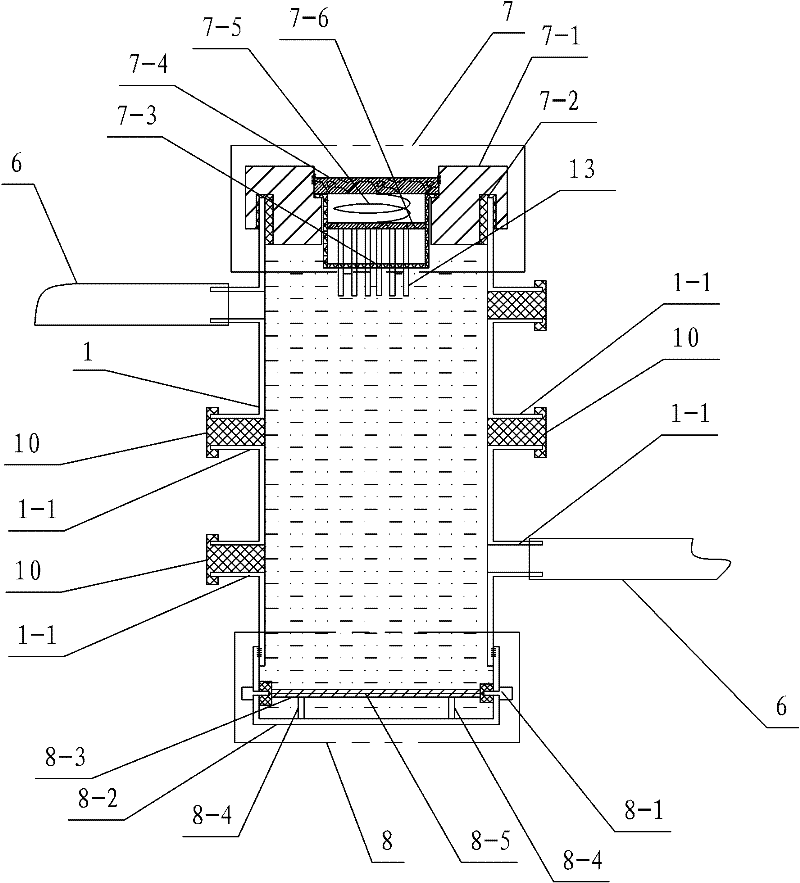

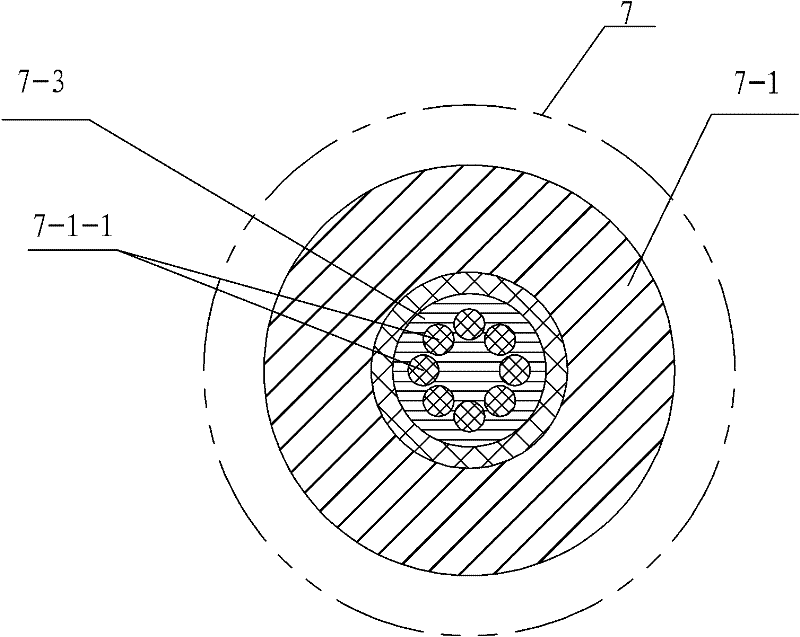

[0007] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the local electroplating device of tiny parts of this embodiment comprises plating tank tank body 1, adjustment tank tank body 3, plating solution circulating filter 4, water bath device 5 and three rubber hoses 6, and adjustment tank 3 is arranged on the water bath In the device 5, the plating tank body 1, the plating solution circulation filter 4 and the adjustment tank 3 are arranged in sequence from left to right, and the plating solution circulation filter 4 and the adjustment tank 3 are connected through a rubber hose 6, and the local electroplating of tiny parts The device also includes a plating tank cover 7, an anode bottom tank 8, an adjustment tank cover 9, a plurality of nozzle plugs 10 and a group of tiny parts 13, a plurality of nozzles 1-1 are set on the plating tank body 1, and the plating One nozzle 1-1 of the tank body 1 communicates with the plating solution circula...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 and figure 2 To describe this embodiment, a plurality of nozzles 1-1 of this embodiment are arranged symmetrically on the body 1 of the plating tank, and the plurality of nozzles 1-1 on the same side are arranged up and down. In this way, a plurality of nozzles 1-1 are arranged symmetrically on both ends of the side wall of the plating tank body 1, and two nozzles 1-1 can be selected to enter and exit the plating solution according to research needs, which is not only easy to operate, but also can be used as a spare. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 and figure 2 This embodiment is described, the anode bottom tank body 8-2 of this embodiment is screwed to the plating tank body 1 . In this way, the anode bottom tank body 8-2 is connected with the plating tank body 1 with threads, and the raw material tape is wound between the threads to prevent the leakage of the plating solution. At the same time, according to the different electroplating systems, anodes with different anode materials can also be made. The bottom tank body 8-2 can be replaced at any time as required. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0015] Specific implementation mode four: combination figure 1 and Figure 5 To illustrate this embodiment, the adjustment tank cover 9 of this embodiment is provided with an adjustment tank plating solution circulation port 9-1, an electrode insertion port 9-2, a temperature sensor insertion port 9-3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com