Method for treating wastewater in production of sebacic acid

A technology for the production of wastewater and sebacic acid, which is applied in natural water treatment, multi-stage water/sewage treatment, heating water/sewage treatment, etc., and can solve problems such as no fully mature economic and industrial solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

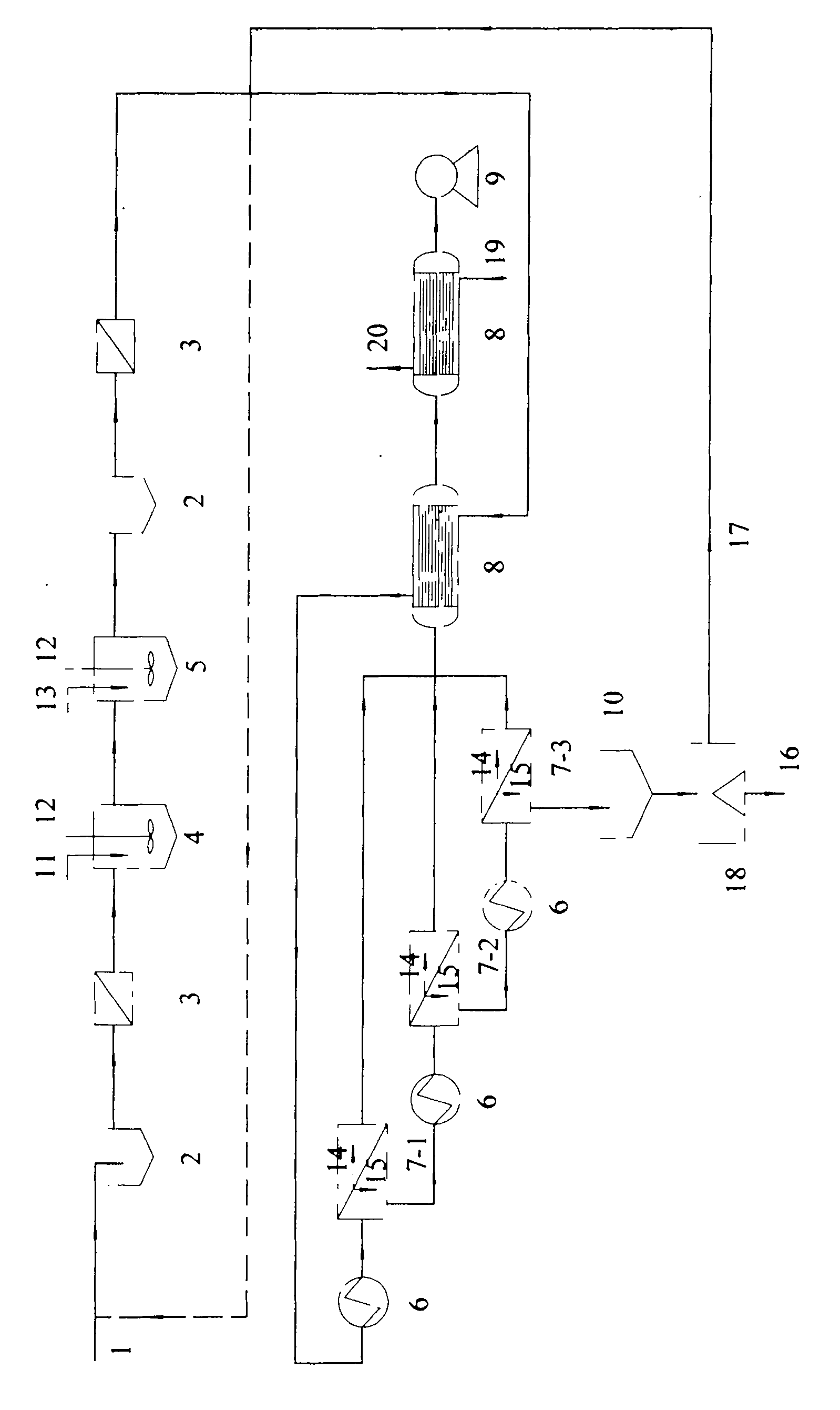

Image

Examples

Embodiment 1

[0015] The COD content in sebacic acid production wastewater A is 9000-10000mg / l (main components: about 0.08% sebacic acid and its derivatives, 2500mg / l phenol and m-cresol, etc.), sodium sulfate content 8-10%, pH Value 2-3.

[0016] After 48 hours of static precipitation, the wastewater discharged from the production is filtered through a 0.2 micron filter, neutralized with sodium hydroxide in the neutralization tank to a pH of 8, and then subjected to membrane distillation after precipitation and filtration. The salt concentration in the water is 14%, which is concentrated to 30% by the second-stage membrane distillation. The feed liquid inlet temperature of the membrane distillation is 85° C., and the vacuum degree on the downstream side is 0.075Mpa. The second-stage membrane distillation concentrated drainage enters the crystallization tank to cool down and crystallize, then centrifuge and purify to obtain industrial grade sodium sulfate solid salt. The extracted steam i...

Embodiment 2

[0018] The COD content in the sebacic acid production wastewater B is 6000-8000mmg / l (the main components are sebacic acid and its derivatives, phenol, etc.), the sodium sulfate content is 11%, and the pH value is 1-2.

[0019] After 15 hours of static precipitation, the waste water from production is filtered by sand filter and 0.4 micron filter, neutralized with sodium carbonate in the neutralization tank to pH 10, then added flocculant for flocculation and precipitation, and the clear liquid is filtered by microfiltration membrane Carry out membrane distillation, the salt concentration in the concentrated water discharged from the first-stage membrane distillation is 20%, and the second-stage membrane distillation concentrates it to 31%, the feed liquid inlet temperature of membrane distillation is 90°C, and the vacuum degree of the downstream side is 0.082Mpa . The second-stage membrane distillation concentrated drainage enters the crystallization tank to cool down and cry...

Embodiment 3

[0021] The COD content in sebacic acid production wastewater C is 10,000-11,000 mg / l (the main components are alcohols, sebacic acid and its derivatives, phenol, etc.), the sodium sulfate content is 7%, and the pH value is 2-3.

[0022] After 24 hours of static precipitation, the wastewater discharged from production is filtered by primary filtration and 0.2 micron filter, neutralized with quicklime in the neutralization tank to a pH of 12, and then statically precipitated, and the clear liquid is filtered by primary filtration and microfiltration membrane respectively. Membrane distillation, waste water is concentrated to 29% by membrane distillation once, the feed liquid inlet temperature of membrane distillation is 95°C, and the vacuum degree on the downstream side is 0.088Mpa. Membrane distillation concentrated drainage enters the crystallization tank to cool down, crystallize, and then separate and purify to obtain industrial grade sodium sulfate solid salt. The extracted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com