Washing machine with circulating water treatment function and control method thereof

A technology for circulating water and washing machines, applied in the field of washing machines, which can solve the problems of inability to recycle and use laundry water, and achieve the effects of reducing pollution and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

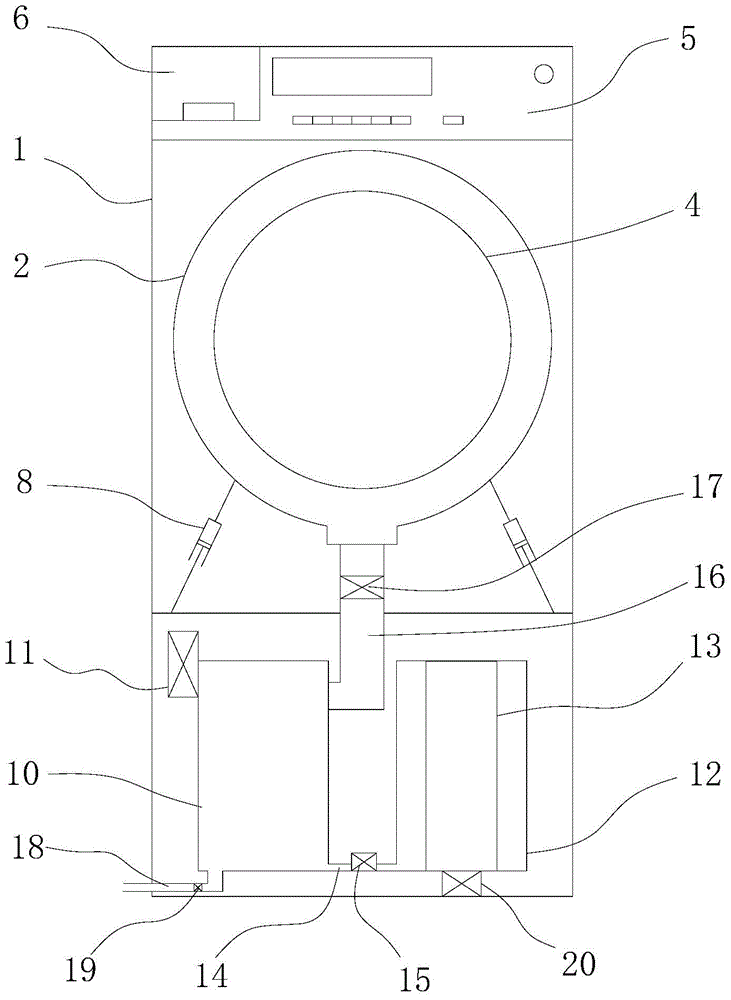

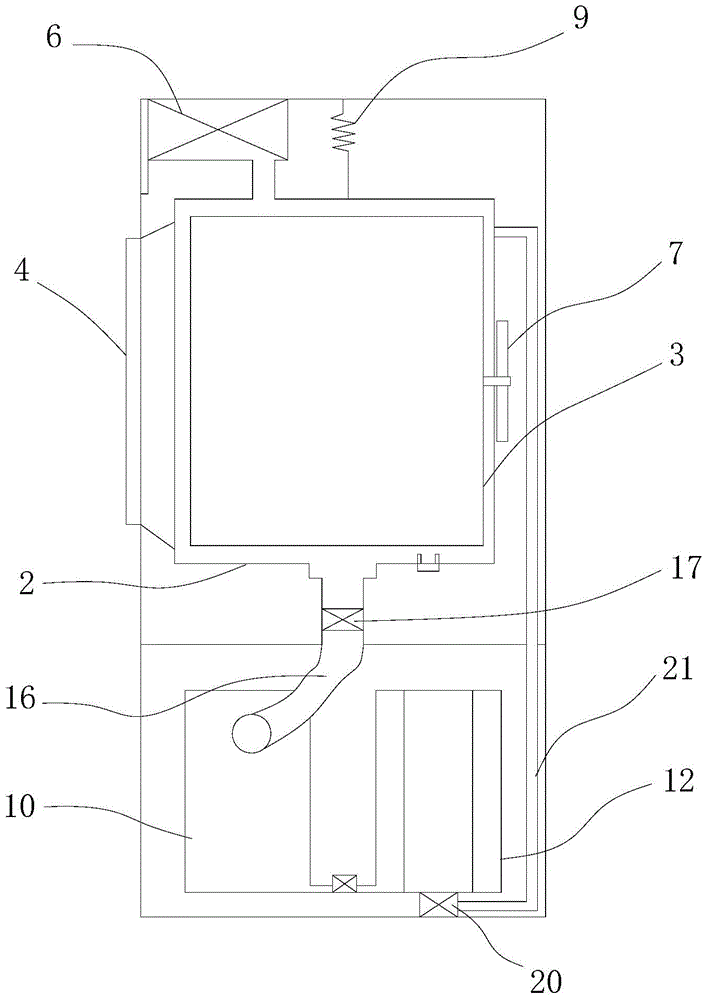

[0039] Such as figure 1 and figure 2As shown, the flocculation container 10 and the filter container 12 described in this embodiment are arranged side by side under the outer cylinder 2. A stop valve 15 is provided to control the connection / disconnection between the two containers. The upper part of the flocculation container 10 communicates with the water outlet at the bottom of the outer cylinder 2 through the water guide pipe 16, and the water guide pipe 16 is provided with a water outlet control valve 17. The bottom of the flocculation container 10 is provided with a drainage structure for draining to the outside of the washing machine, including a drainage port of the flocculation container, a drain pipe 18 and a drain valve 19 communicating with the drain port.

[0040] Further, the filter container 12 is provided with a circulating water structure for discharging filtered water into the outer cylinder 2, including a circulating water outlet of the filter container, a...

Embodiment 2

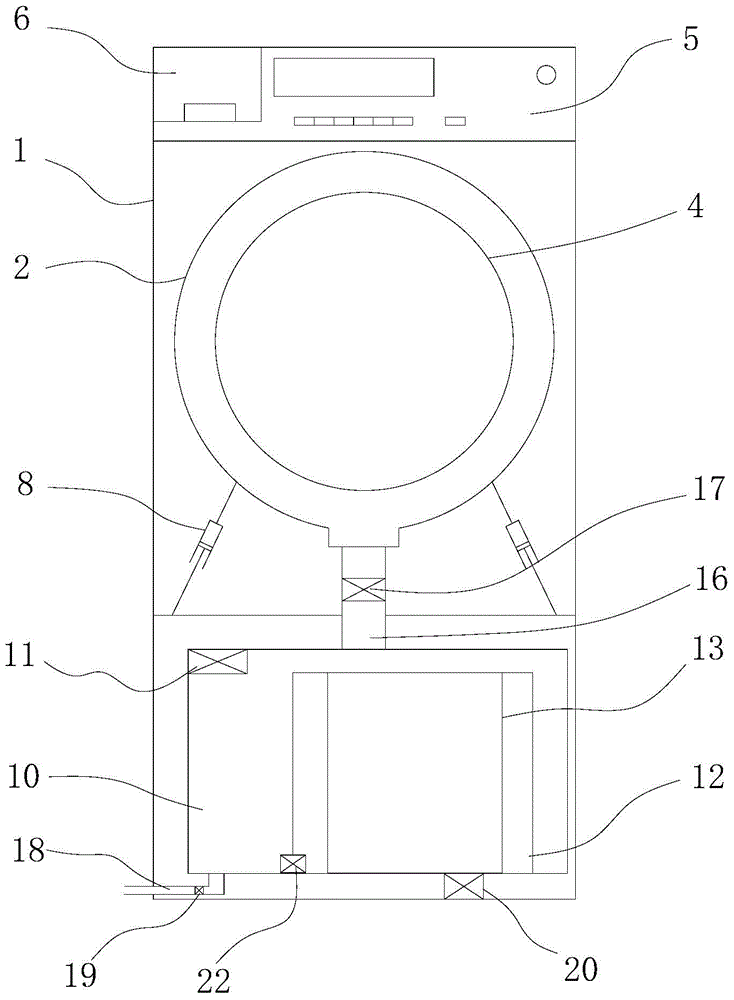

[0042] Such as image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the filter container 12 is arranged inside the flocculation container 10, the chamber between the filter container 12 and the flocculation container 10 is used for flocculation treatment water, and the lower part of the filter container 12 is provided with There is a port, and the port is provided with an on-off control structure 22 for controlling the connection / disconnection between the two containers.

Embodiment 3

[0044] Such as Figure 5 and Figure 6 As shown, the flocculation container 10 described in this embodiment is arranged above the filter container 12, the bottom of the flocculation container 10 communicates with the upper part of the filter container 12 through a connecting pipe 14, the connecting pipe 14 is provided with a stop valve 15, and the upper part of the flocculation container 10 is connected to The water outlet at the bottom of the outer cylinder 2 is communicated through the water guide pipe 16, and the water guide pipe 16 is provided with a water outlet control valve 17.

[0045] The bottom of the filter container 12 is provided with a drainage structure for draining water to the outside of the washing machine and a circulating water structure for discharging filtered water into the outer cylinder 2. The filter screen 13 divides the inside of the filter container 12 into two parts. The connecting pipe 14 communicates with the drainage structure, and the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com