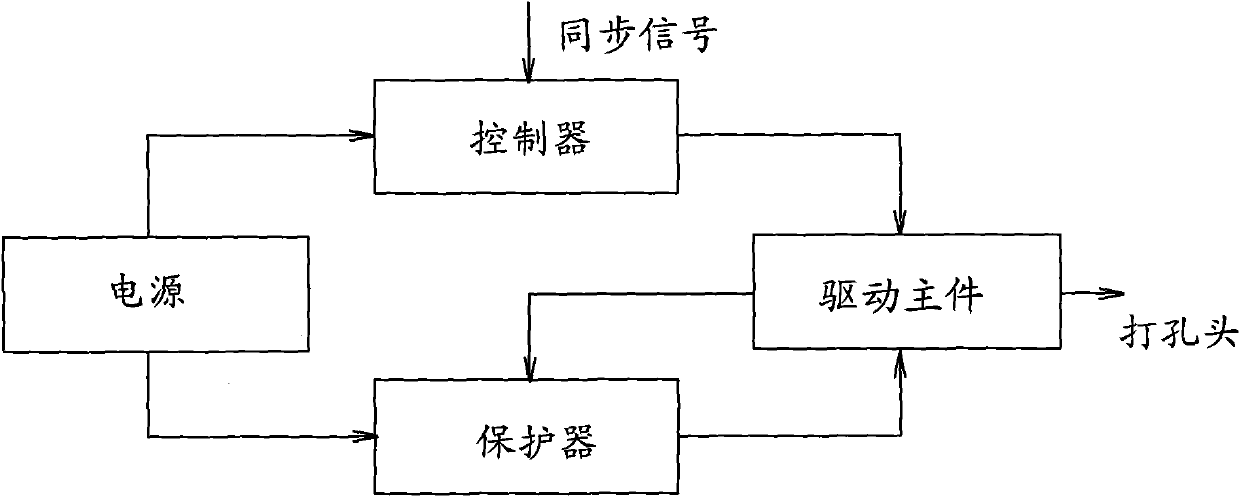

Quick plaster ionic perforating machine perforating head driver

A driver and punching machine technology, applied in metal processing, etc., can solve the problems of low production efficiency and poor synchronization of drilling, and achieve the effects of high production efficiency, improved production efficiency and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

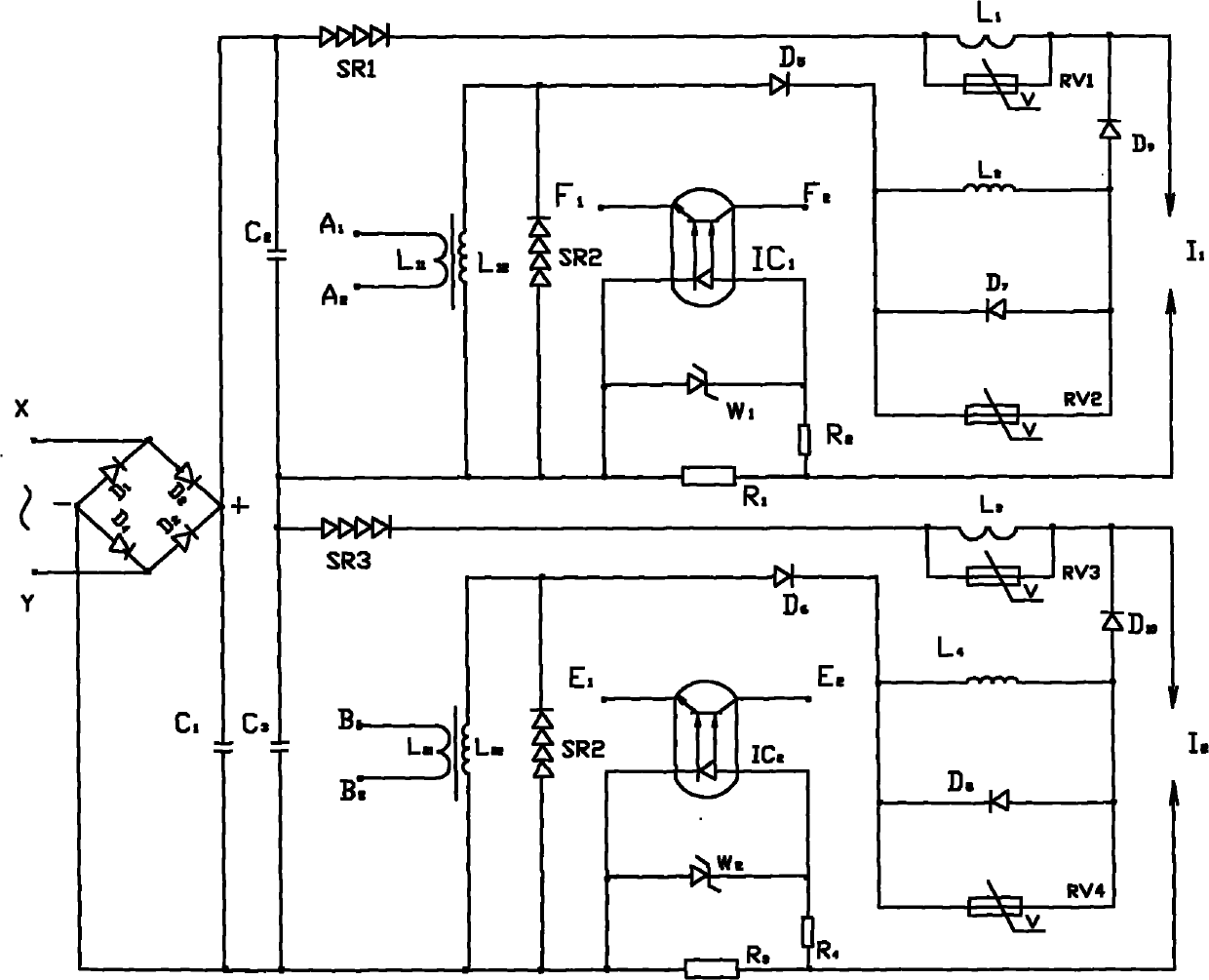

[0016] combine figure 2 , Figure 5 , further explain the main circuit of the driver:

[0017] The main part of the driver is connected to 220V-110V at both ends of X and Y, adjustable 50H Z comminicate. via diode D 1 -D 4 The composed rectified full bridge is transformed into pulsating DC, which is output from the "+" and "-" ends of the bridge. Through capacitance C 1 Filter to obtain a smooth DC voltage. by capacitance C 2 , high pressure stacking SR 1 , Transformer H 1 , high voltage silicon stack SR 2 , Diode D 5 ,D 7 ,D 9 , inductance L 1 , L 2 , varistor RV 1 , RV 2 , forming the driving electrode pair I 1 (spark plug) drive circuit.

[0018] by capacitance C 3 , high voltage silicon stack SR 3 , SR 4 , Transformer H 2 , Diode D 6 ,D 8 ,D 10 , and inductance L 3 , L 4 , varistor RV 3 , RV 4 , constituting the driving electrode pair I 2 (Spark plug) drive circuit. Drive electrode pair I 1 and drive electrode pair I 2 The circuit structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com