Assistive device tool for placing working tools

A technology for tooling and auxiliary tools, applied in the field of auxiliary tools for placing tooling, can solve the problems of inconvenient access, small number of display, large volume, etc., and achieve the effects of low cost, good durability, and easy access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

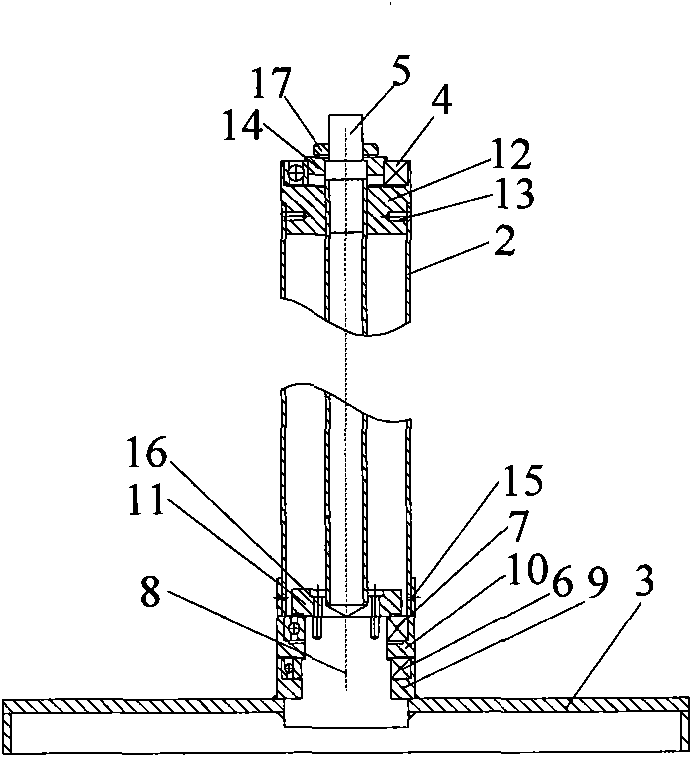

[0020] Embodiment 1, according to the principle of "in the case of the same volume, the space occupied by the ring or circle is the smallest", the present invention adopts a ring tree structure design, so that the present invention reduces the occupation of the site and frees up space for the operation of employees . like figure 1 , 2 As shown, an auxiliary device for placing tooling, including a base 3 and a rotating column 2, on which a plurality of hanging arms 1 for hanging tooling are arranged. The mandrel 5 is fixedly arranged on the base 3 , the mandrel 5 is movably socketed in the rotating column 2 , and the rotating column 2 can rotate relative to the base 3 .

Embodiment 2

[0021] Embodiment 2, on the basis of the technical solution of Embodiment 1, in order to make the rotating column rotate smoothly and maintain the stability of the auxiliary device, the bottom end of the mandrel 5 is connected to the large shaft 8 fixed to the base, and the bottom end of the large shaft 8 is provided with a second A bearing seat 9 and an eccentric ball type first bearing 6; the second bearing seat 12 is fixed by the first screw 13 in the top end of the rotating column 2, the second bearing seat 4 is arranged in the second bearing seat 12, and the mandrel 5 is socketed Second bearing 4.

Embodiment 3

[0022] Embodiment 3, on the basis of the technical solution of Embodiment 2, in order to make the rotating column more smooth and easy to disassemble and maintain, a third bearing seat 10 and a third bearing 7 are arranged above the first bearing 6, and the third bearing The seat 10 is fixedly connected with the rotating column 2 through the second screw 15; the bottom end of the mandrel 5 is provided with a large end cap 11, and is connected with the large shaft 8 through a bolt 16; the top end of the mandrel 5 is provided with a small end cap 14 and The nut 17, after the nut 17 is tightened, the small end cover 14 compresses the second bearing 4.

[0023] Both the second bearing and the third bearing are deep groove ball bearings. Described first screw, second screw adopt hexagon socket head cap screw.

[0024] For safety, an opening safety guardrail is also provided outside the auxiliary device. like image 3 , 4 shown. Eliminate possible hidden dangers in the process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com