Exchanging method of exhaust-heat boiler low temperature economizer

A low-temperature economizer and waste heat boiler technology, which is applied to feed water heaters, preheating, lighting and heating equipment, etc., can solve the problems of long replacement period, high cost, and heavy workload, and achieve convenient replacement and save construction period and construction cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

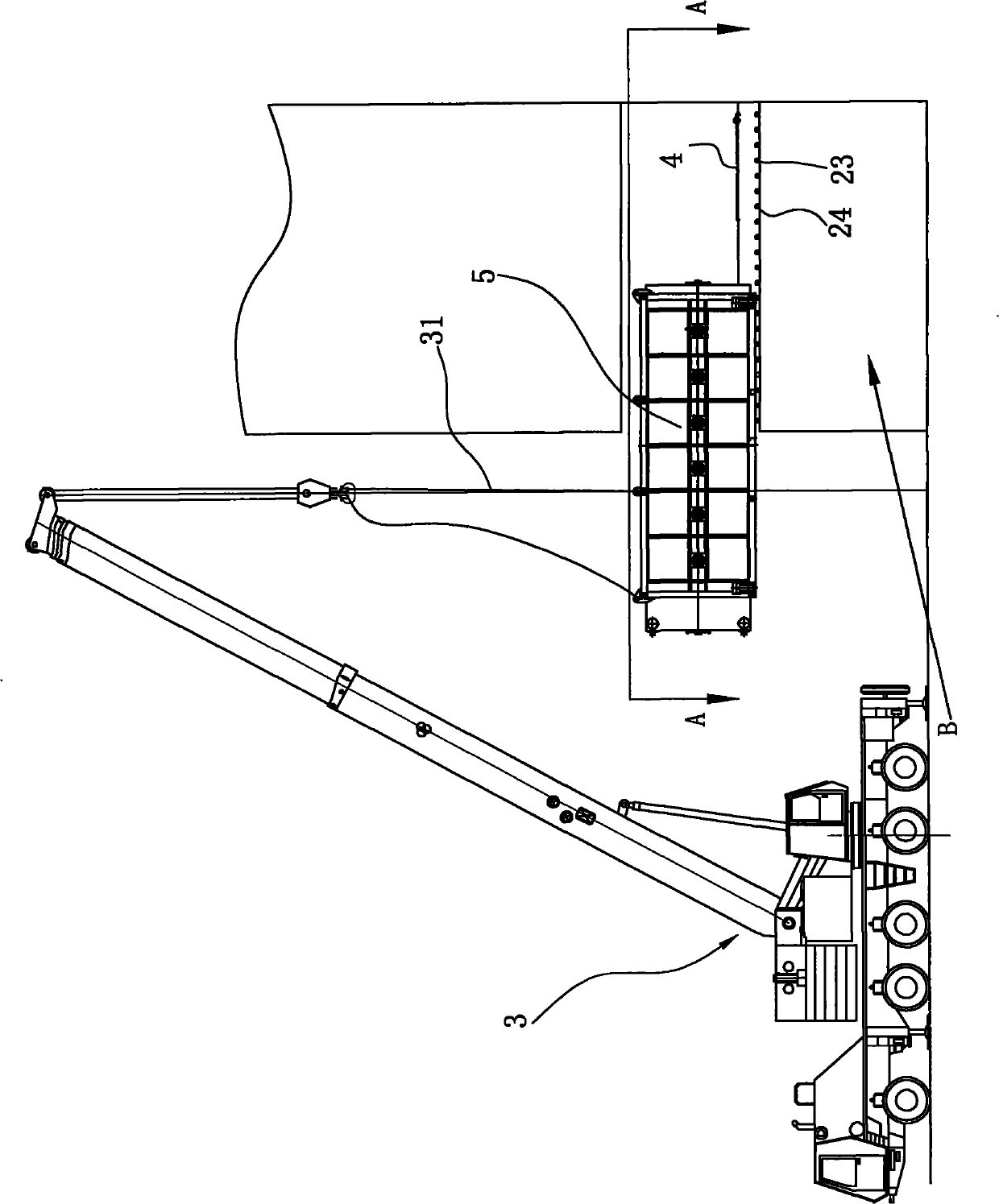

[0029] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

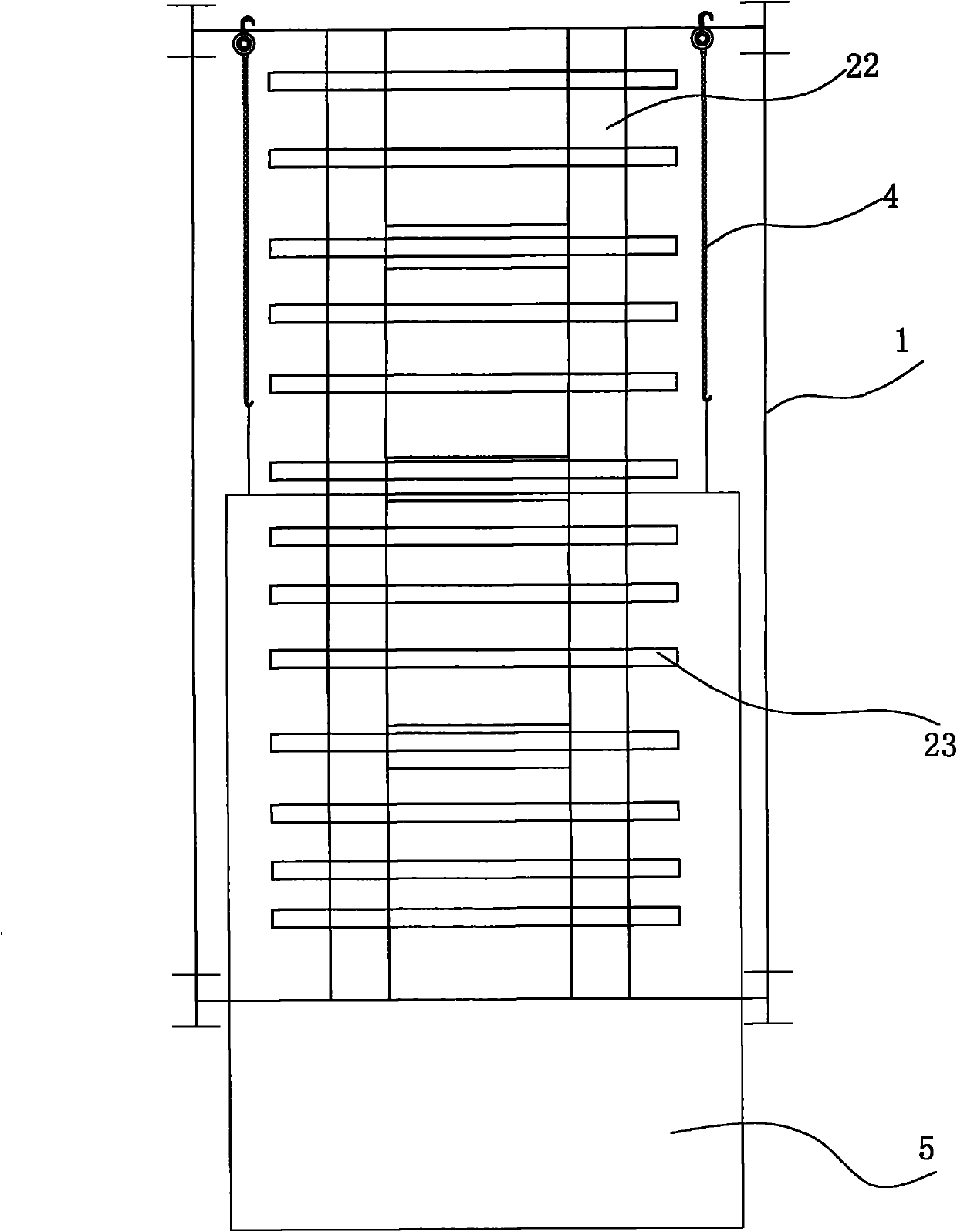

[0030] In the prior art, the low-temperature economizer module bracket 1 is a three-dimensional frame formed by welding angle steel, which constitutes a total of six side openings: upper, lower, left, right, front and rear; and each angle steel constituting the bracket is folded inward. , the low temperature economizer module is located on the folded edge of each angle steel and is tightly clamped in the bracket 1 . Eight lifting lugs 12 are also welded on the bracket 1

[0031] like figure 1 As shown, in this embodiment, the height dimension of the new low-temperature economizer module 5 is designed to be slightly smaller than the heights of the left and right side openings of the bracket 1 . Two rows of eight lifting ears 51 are welded on the top surface of the new low-temperature economizer module, and every two lifting ears form a row. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com