Wire rope guide rail tensioning device for mining elevator

A technology of tensioning device and steel wire rope, which is applied in the direction of transportation and packaging, lifting equipment in mines, elevators, etc., can solve the problems of horizontal deflection of lifting containers, difficulty in adjusting the precise weight of heavy hammers, and low work efficiency, so as to avoid horizontal yaw, wide availability, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

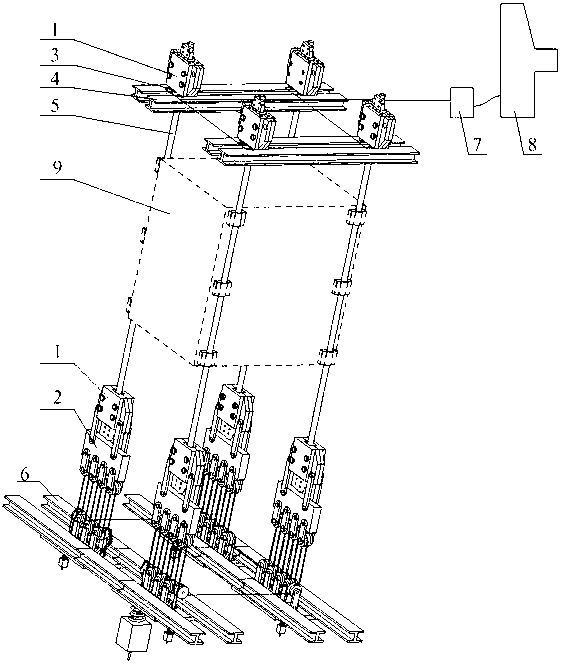

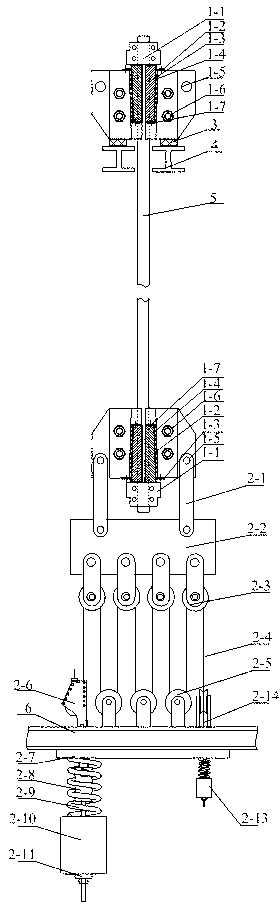

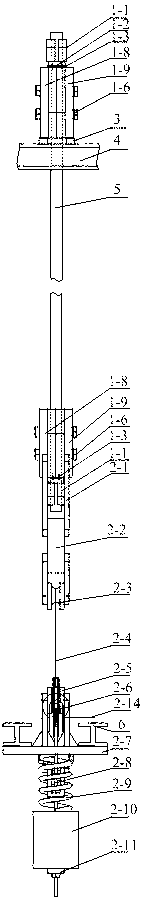

[0015] figure 1 As shown, the mining elevator wire rope guide rail tensioning device of the present invention is mainly composed of an industrial computer 8, a signal collector 7 connected to the industrial computer 8, four wire rope guide rails 5 symmetrically arranged on both sides of the car box 9, and the upper and lower wire ropes are fixed. Device 1 is formed with tensioning device 2, counterweight device and rope adjustment device that are located on the lower wire rope fixing device. figure 2 , 3 As shown, the upper and lower ends of the four wire rope guide rails 5 are respectively provided with oppositely symmetrical wire rope fixing devices. -3 The outer roller grid frame 1-4, the outer end of the roller grid frame 1-4 is provided with an outer baffle plate 1-2, the inner end is provided with an inner baffle plate 1-7, and the two sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com