Vehicle headlamp system

A technology for headlights and vehicles, applied in the field of headlights, can solve problems such as recovery delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

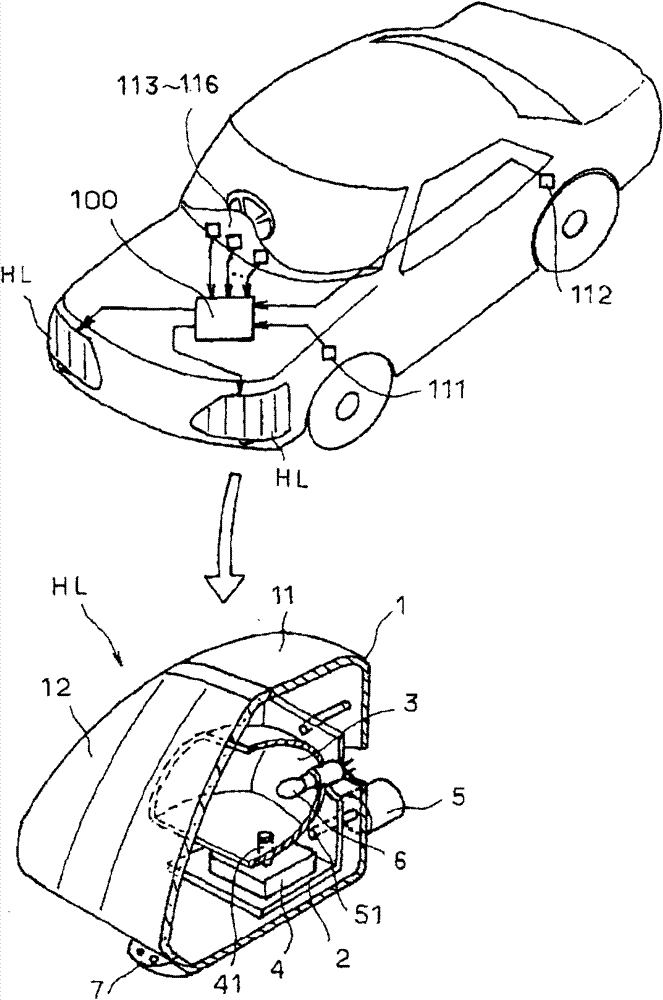

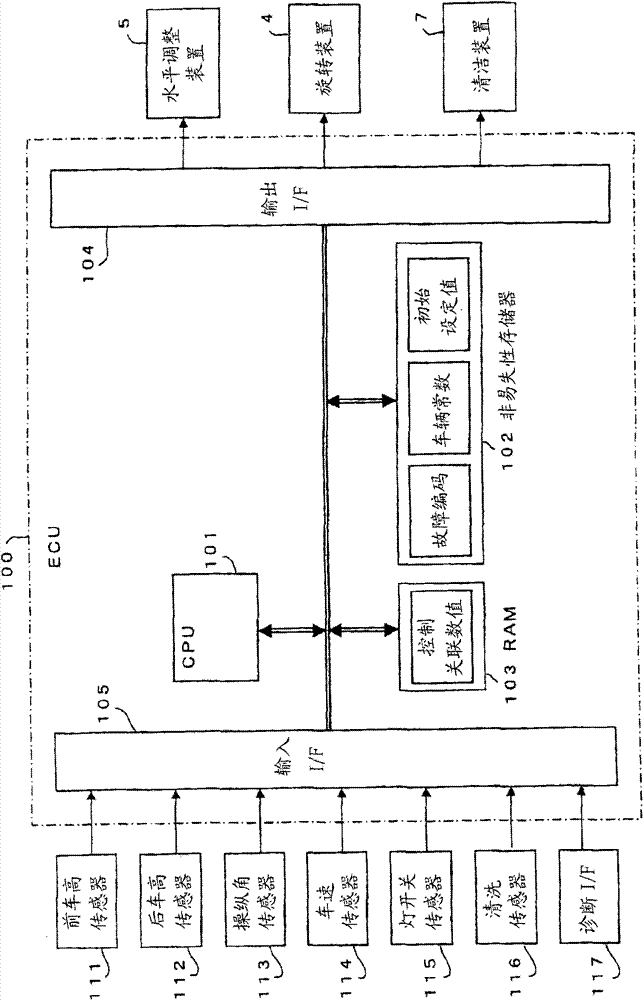

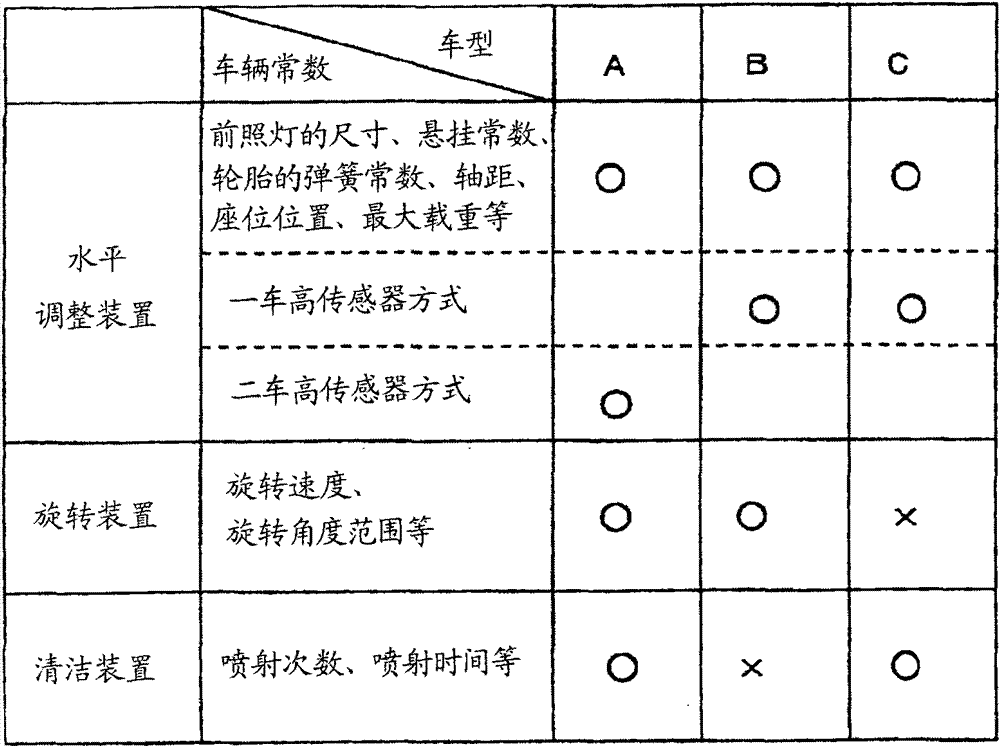

[0043] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a structural schematic diagram of an important part of a motor vehicle to which the system of the present invention is applied. Headlamps HL are respectively arranged on the left and right in the front part of the vehicle, and a plurality of control mechanisms for changing and controlling the light irradiation form such as the light irradiation direction are incorporated in each of these headlights HL. In this embodiment, as the control mechanism, a horizontal adjustment device for controlling the deflection of the light axis of the headlight HL in the vertical direction, a rotating device for controlling the deflection of the light axis of the headlight HL in the horizontal direction, It is a cleaning device for removing the sludge and dust adhering to the front lens of the headlamp. which is, figure 1 The schematic cross-sectional structure of the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com