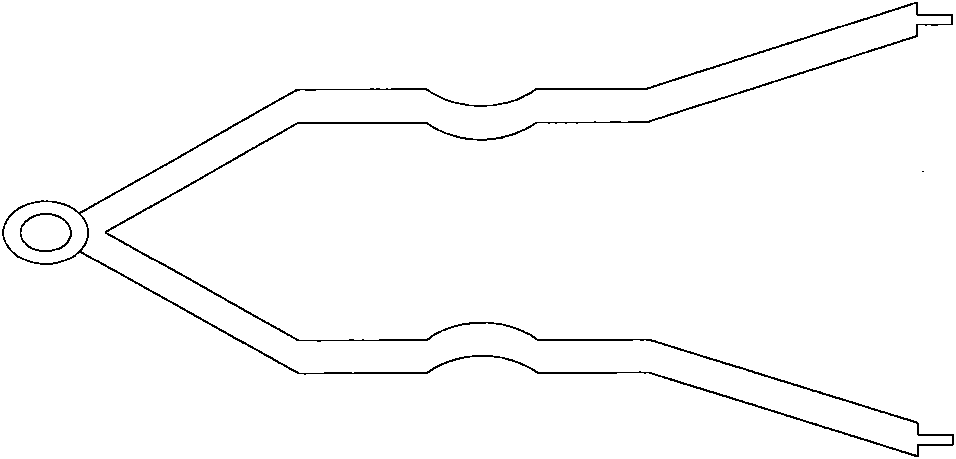

Large-diameter PE straight-wall pipe startup molding and towing device and startup method thereof

A pulling device and large-diameter technology, which is applied to tubular articles, aluminothermic welding equipment, manufacturing tools, etc., can solve the problems such as the difficulty of welding the tube blank and the pulling tube successfully at one time, the time-consuming and laborious insertion of the pulling tube, and the outer diameter of the waste tube. , to achieve the effect of saving resources, reducing preparation time and labor, and reducing startup waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0038] Aiming at the problems existing in the prior art, the new start-up forming method provided by the present invention adopts a steel wire rope coiling device to pull the tube blank, and installs an air intake pipeline on the extrusion die, and the tube blank itself is bonded and sealed during molding. The air intake of the intake pipeline adopts internal pressure shaping, and after the tube blank passes through the first section of the vacuum box, it is changed to negative pressure forming. This method saves a lot of traction tubes, less preparation work before starting, fast starting speed, and high success rate , suitable for pipes of different specifications.

[0039] Based on above-mentioned principle, concrete realization of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com