Multifunctional composite additive for wet-method flue gas desulfuration process and using method thereof

A wet flue gas desulfurization and compound additive technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the desulfurization efficiency decline, system scaling and overflow, affecting the comprehensive utilization of desulfurized gypsum, and the crystallization of desulfurized gypsum. Defects and other problems, to achieve the effect of inhibiting the formation of soft scale, facilitating the operation of the system, and improving the utilization rate of calcium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The compound additive of this embodiment is made up of following components: nylon acid, sodium humate, organosilicon defoamer, potassium formate, manganese sulfate and p-hydroxybenzoic acid, nylon acid, sodium humate, organosilicon defoamer in compound additive The most preferred mass percentages of foaming agent, potassium formate, manganese sulfate and p-hydroxybenzoic acid are respectively: 40%, 40%, 8%, 4%, 4%, 4%, and the silicone defoamer is modified Polysiloxane, the content of adipic acid in the nylon acid is greater than 50%.

[0025] Get 80g of calcium carbonate, 100g of calcium sulfite and dissolve it in 1L of deionized water, add compound additives of different qualities respectively, and measure the dissolution rate of limestone on the calcium carbonate dissolution rate test bench with the method of dilute sulfuric acid titration, the experiment shows that , adding 400mg / L of composite additives increases the dissolution rate of limestone by 1.4 times; add...

Embodiment 2

[0027] The compound additive of this embodiment is made up of following components: nylon acid, sodium humate, organosilicon defoamer, potassium formate, manganese sulfate and p-hydroxybenzoic acid, nylon acid, sodium humate, organosilicon defoamer in compound additive The most preferred mass percentages of foaming agent, potassium formate, manganese sulfate and p-hydroxybenzoic acid are respectively: 40%, 40%, 8%, 4%, 4%, 4%, and the silicone defoamer is modified Polysiloxane, the content of adipic acid in the nylon acid is greater than 50%. .

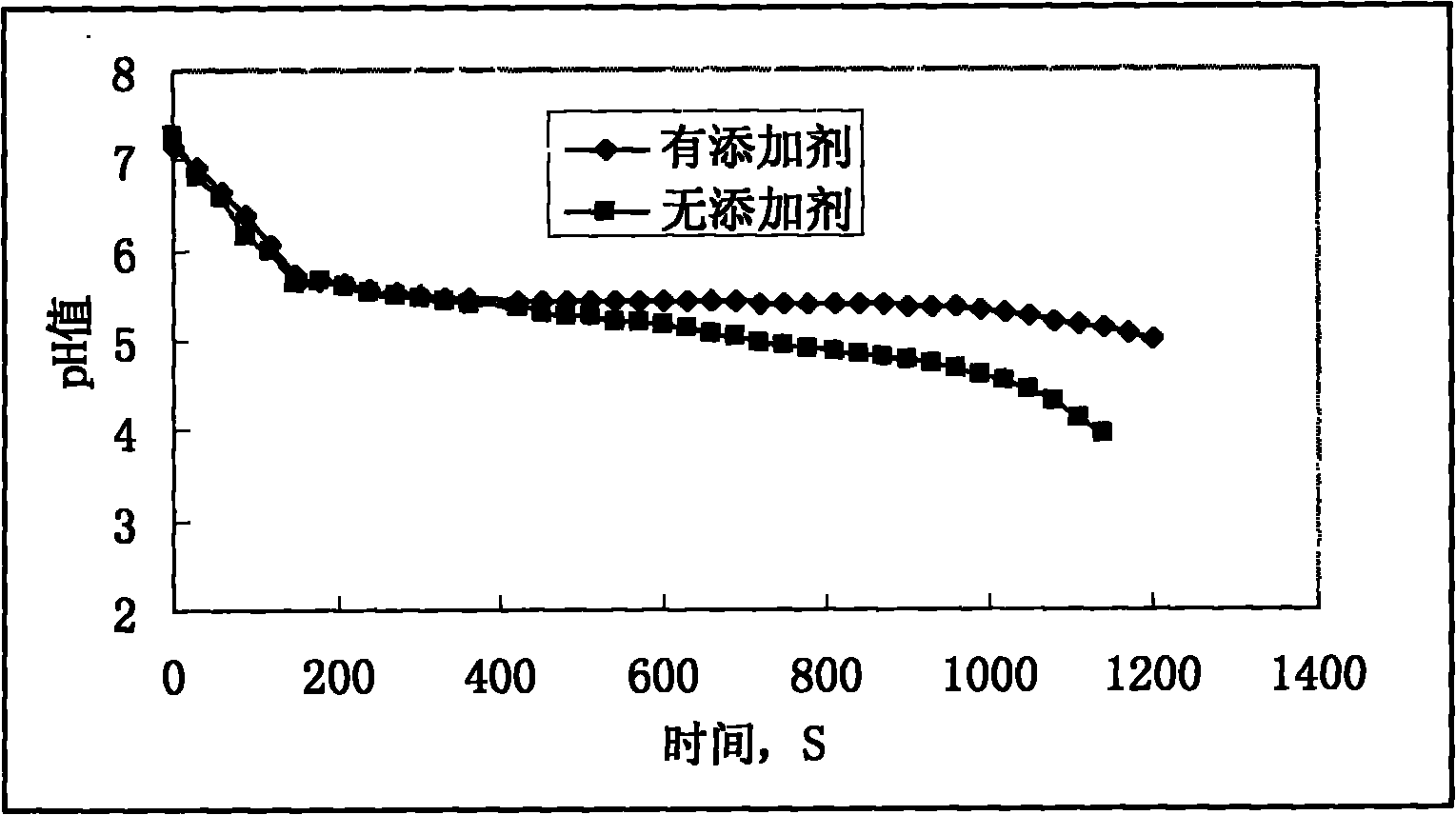

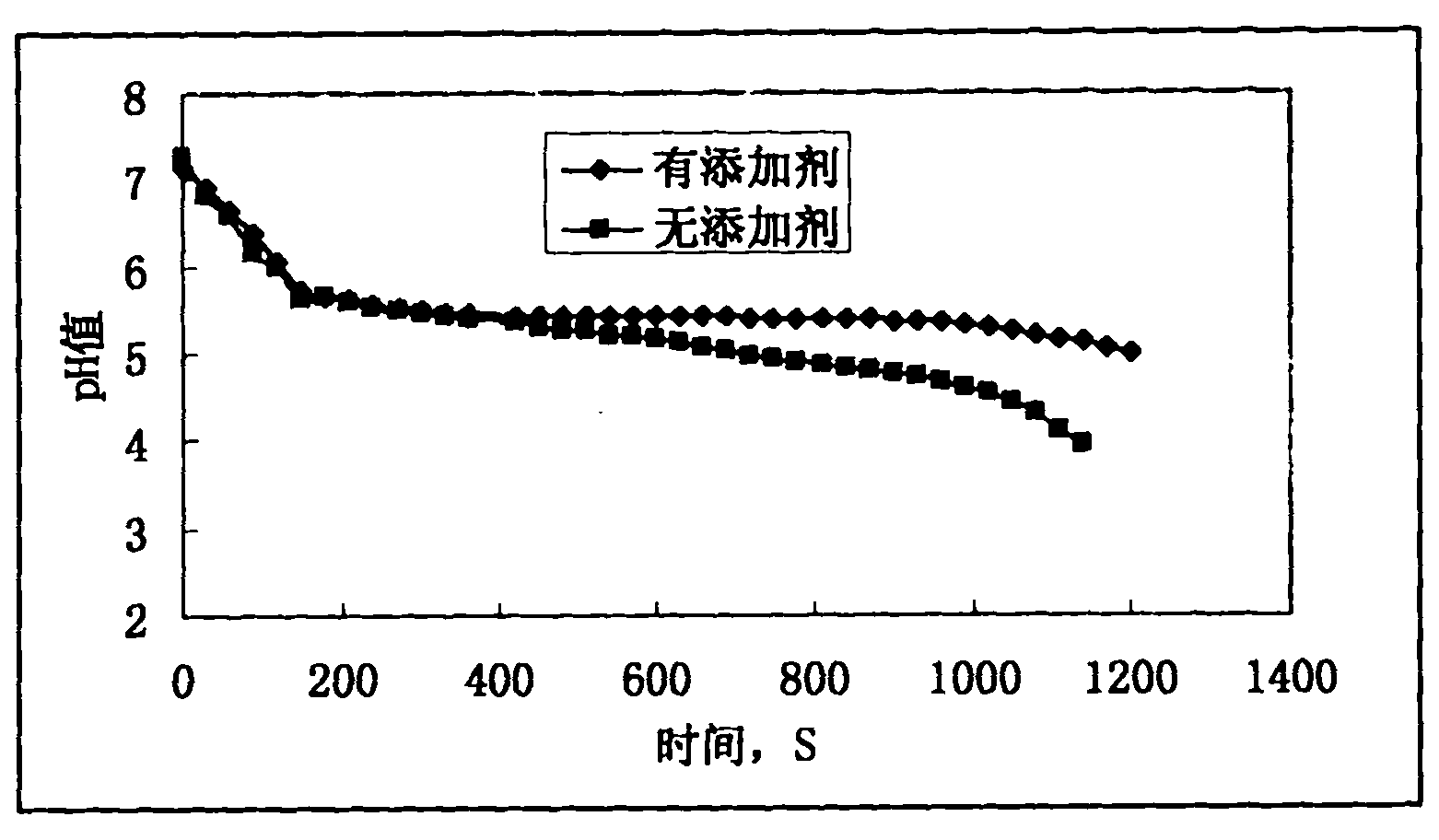

[0028] Get 4g of calcium carbonate, 5g of calcium sulfate and mix with 400ml of deionized water, add 20mg of compound additives and the mixed solution, titrate with 0.95mol / L dilute sulfuric acid and the same titration speed, the change rule of slurry pH value with titration time is as follows figure 1 shown. The figure shows that the composite additive has a buffering effect on the pH of the slurry, which facilitates the operation ...

Embodiment 3

[0030] The compound additive of this embodiment is made up of following components: nylon acid, sodium humate, organosilicon defoamer, potassium formate, manganese sulfate and p-hydroxybenzoic acid, nylon acid, sodium humate, organosilicon defoamer in compound additive The most preferred mass percentages of foaming agent, potassium formate, manganese sulfate and p-hydroxybenzoic acid are respectively: 40%, 40%, 8%, 4%, 4%, 4%, and the silicone defoamer is modified Polysiloxane, the content of adipic acid in the nylon acid is greater than 50%. .

[0031] Add the desulfurization compound additive to the limestone slurry in the limestone gypsum desulfurization experimental system, and the addition amount is 400mg / L. The measured 24-hour desulfurization efficiency of the system is above 93%, which is 5% higher than that without desulfurization compound additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com