Convection heating Kang

A kang and kang body technology, applied in heating methods, household heating, lighting and heating equipment, etc., can solve the problems of less than 45% thermal efficiency of kang stoves, lack of theoretical support, high surface temperature of kang boards, etc., to enhance the overall Heating capacity, improving energy utilization efficiency, and satisfying the effect of sleeping comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

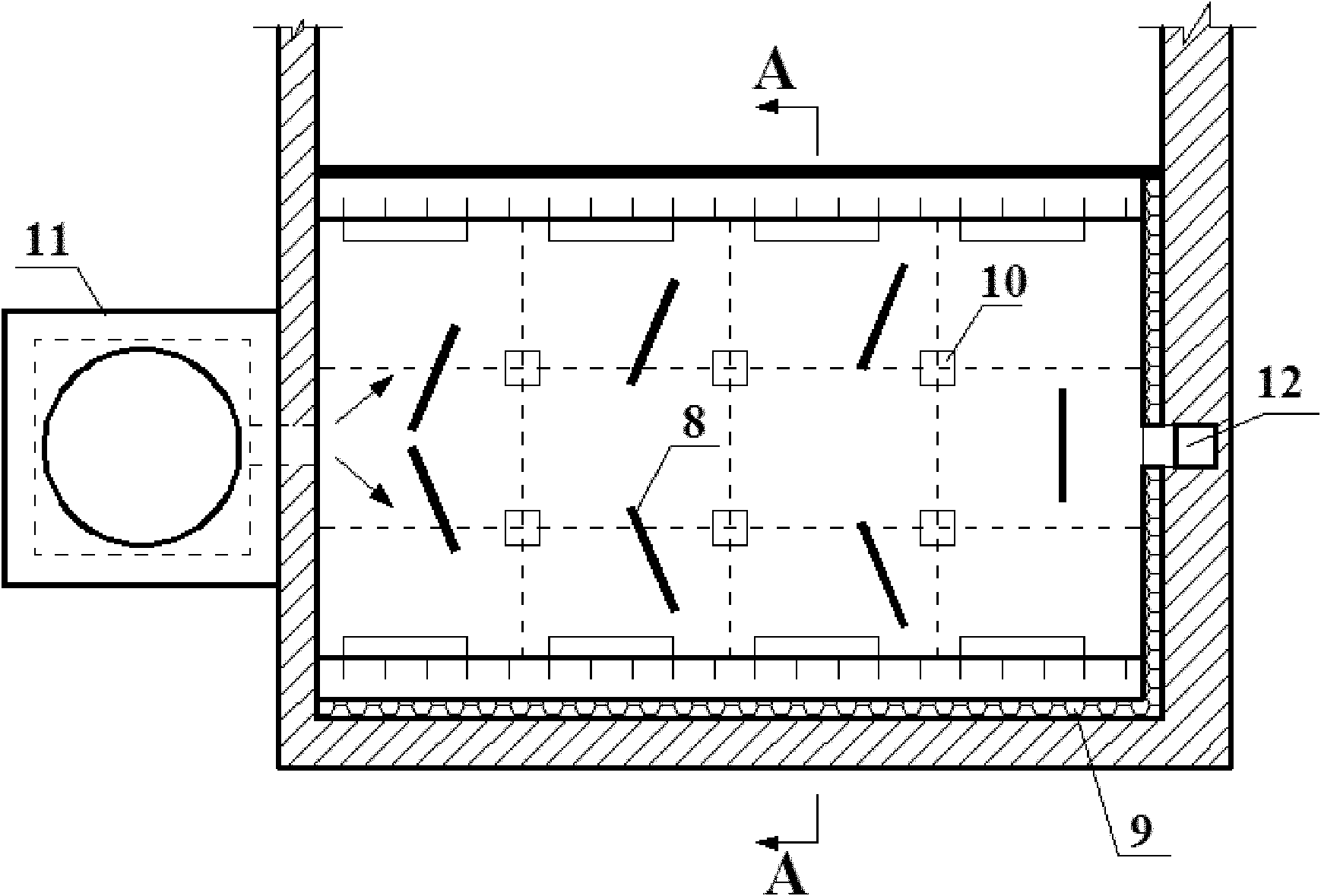

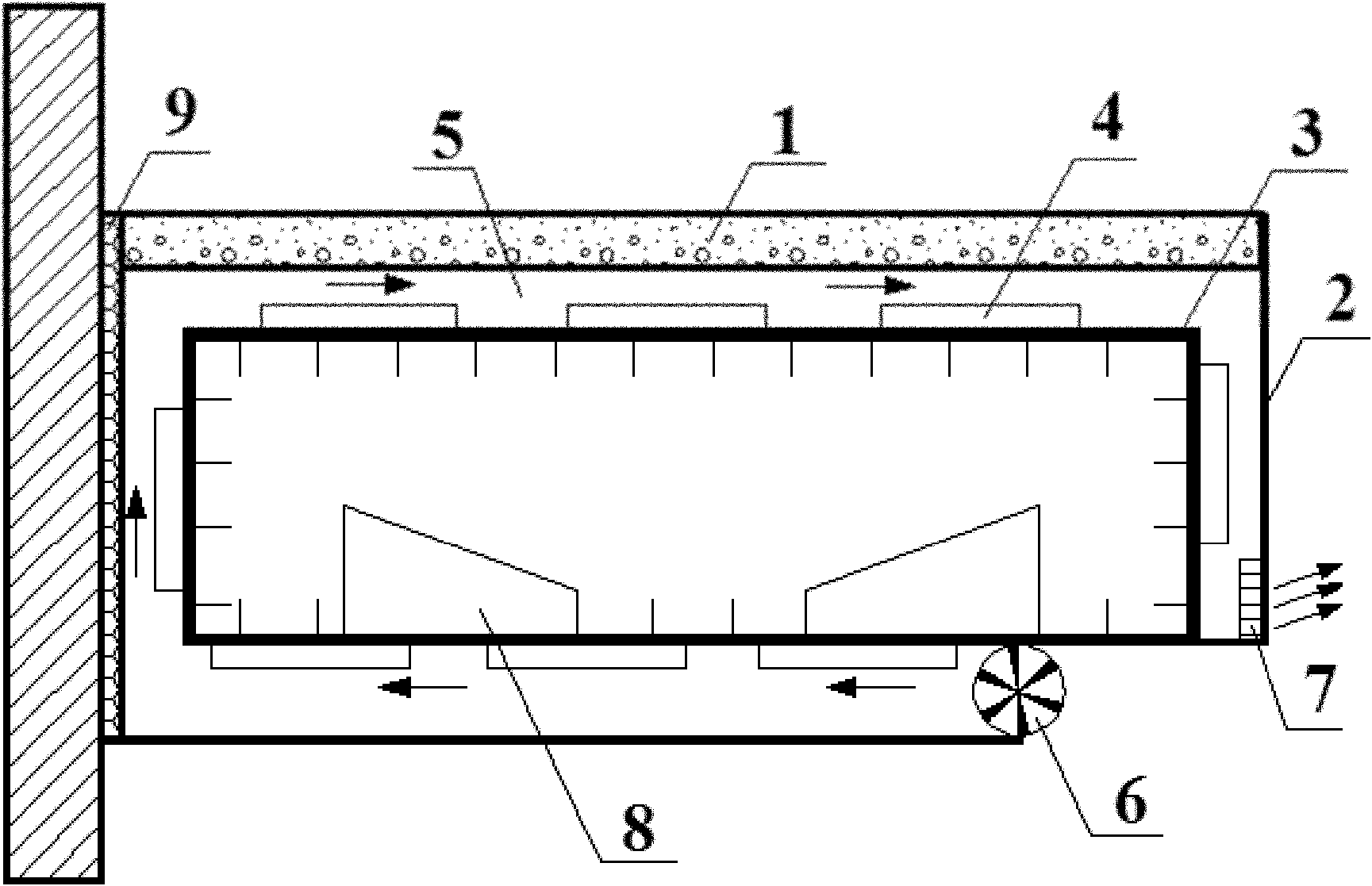

[0015] The working principle and specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] A kind of convection heating heated kang provided by the present invention, its working principle is to utilize the flue gas that kitchen range or stove discharges to flow through inner kang body 3, carry out heat exchange through the wall surface of inner kang body 3 to heat inner kang body 3 and outer kang body. The air in the air channel 5 between the kang bodies 2 is sent to the room by the air outlet 7 under the action of the fan 6, thereby achieving the purpose of heating the indoor air in a convective manner.

[0017] figure 2 for figure 1 The A-A sectional view of the convection heating kang (structural schematic diagram of the convection heating kang), the convection heating kang contains a kang panel 1, the outer kang body 2, the smoke outlet of the stove and the flue gas outlet of the kang, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com