High-precision direct driven air flotation turntable

An air-floating turntable, direct-drive technology, applied in the direction of the machine/support, bearing, shaft and bearing, etc., can solve the problems of small end surface runout and radial runout, achieve small indexing error and friction torque, and excellent dynamics and static stability, the effect of simplifying the mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

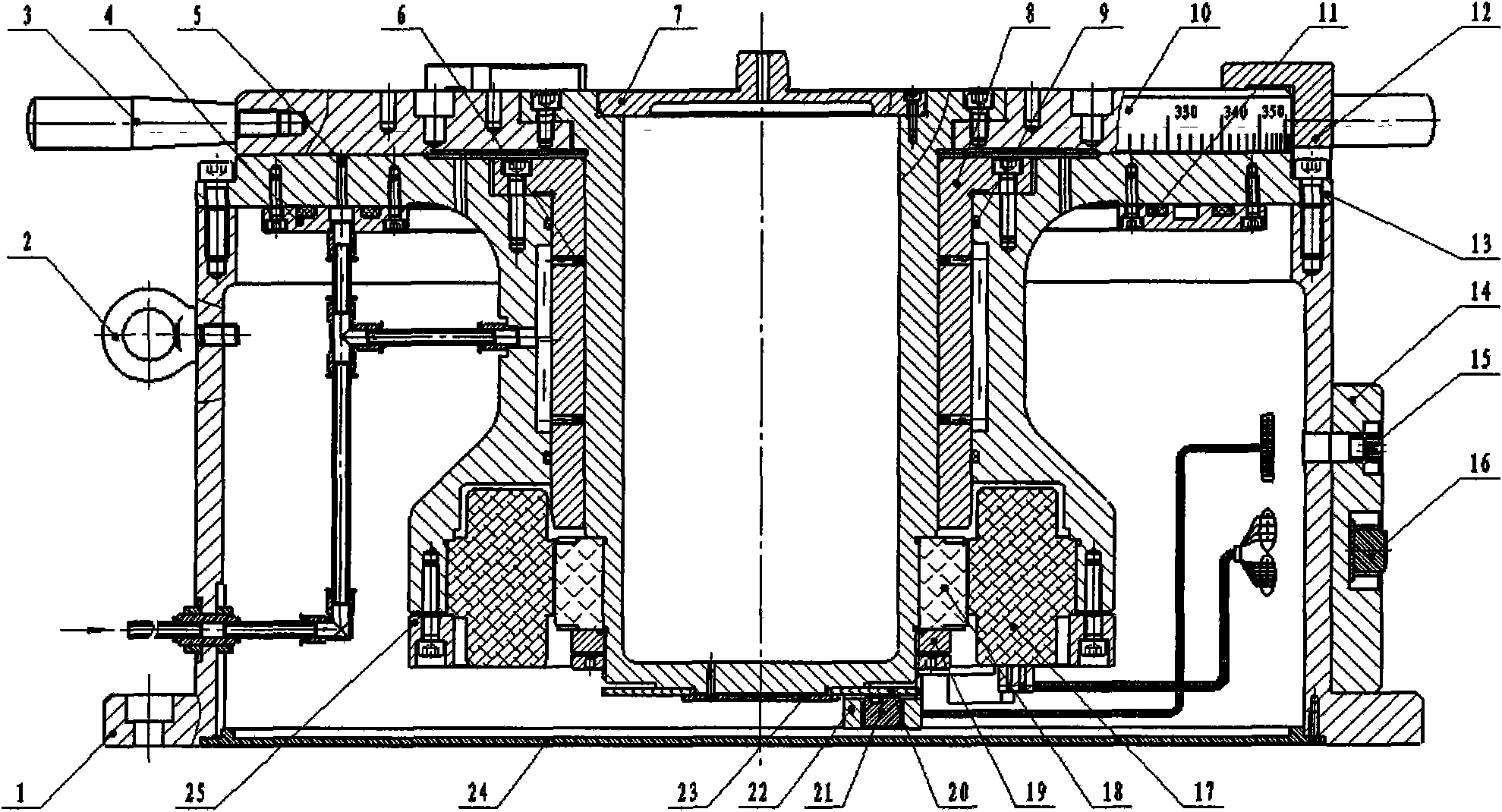

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

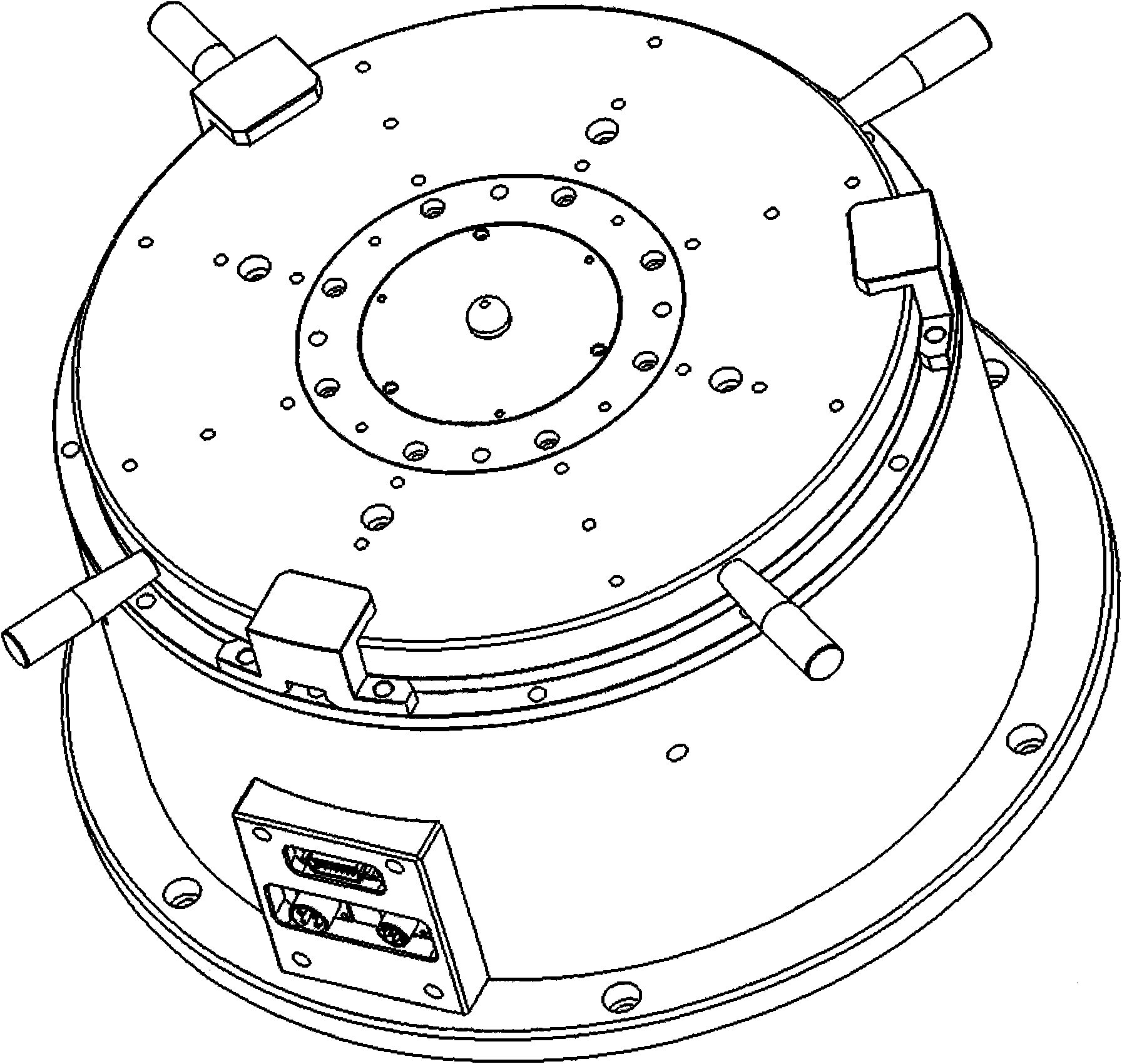

[0018] The shape of the precision indexing turntable of the present invention is as follows: figure 1 Shown:

[0019] A) During transportation, the pressing block 12 needs to be fixed on the motor mounting base 13 by screws to compress the air bearing surface assembly 10 and other parts connected to it, and the pressing block 12 for transportation and the corresponding locking screws need to be removed during use;

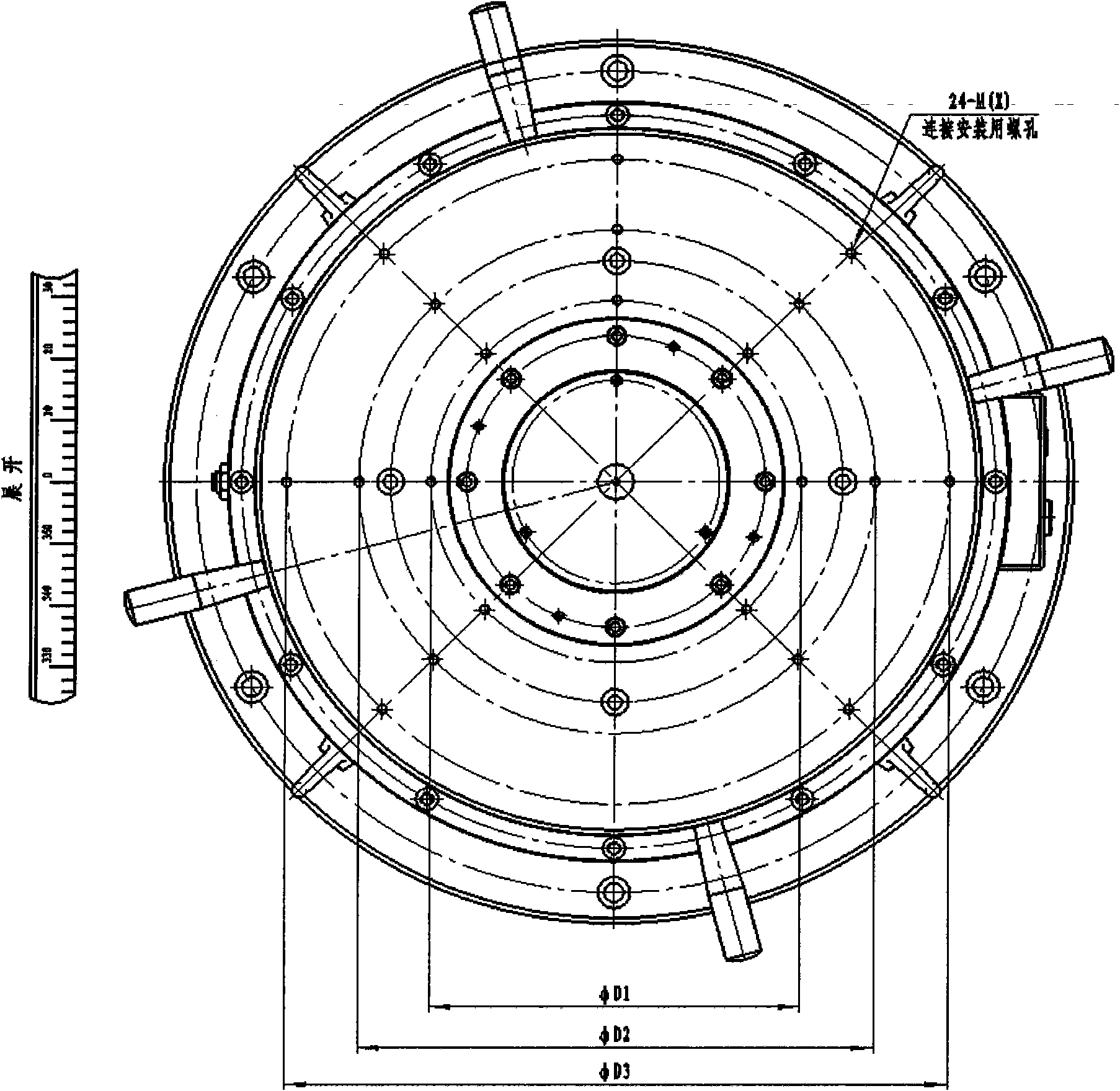

[0020] B) The object to be rotated and driven is fixed on the upper surface of the air bearing surface assembly 10, installed with the installation base 7 as the centering reference, and the air bearing surface assembly 10 as the end face positioning reference, and connected and fixed by screws. For the distribution of the fixing holes, see figure 2 , ΦD1, ΦD2 and ΦD3 are the pitch circle diameters of each mounting hole;

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com