Sectionalized-assembly type fan blade and manufacturing method thereof

A technology for fan blades and a manufacturing method, applied in the field of segmented assembled fan blades and their manufacturing, can solve the problems of large space occupied, high cost, and difficult manufacturing of fan blades, so as to save manufacturing costs, use safety, and save workshops Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

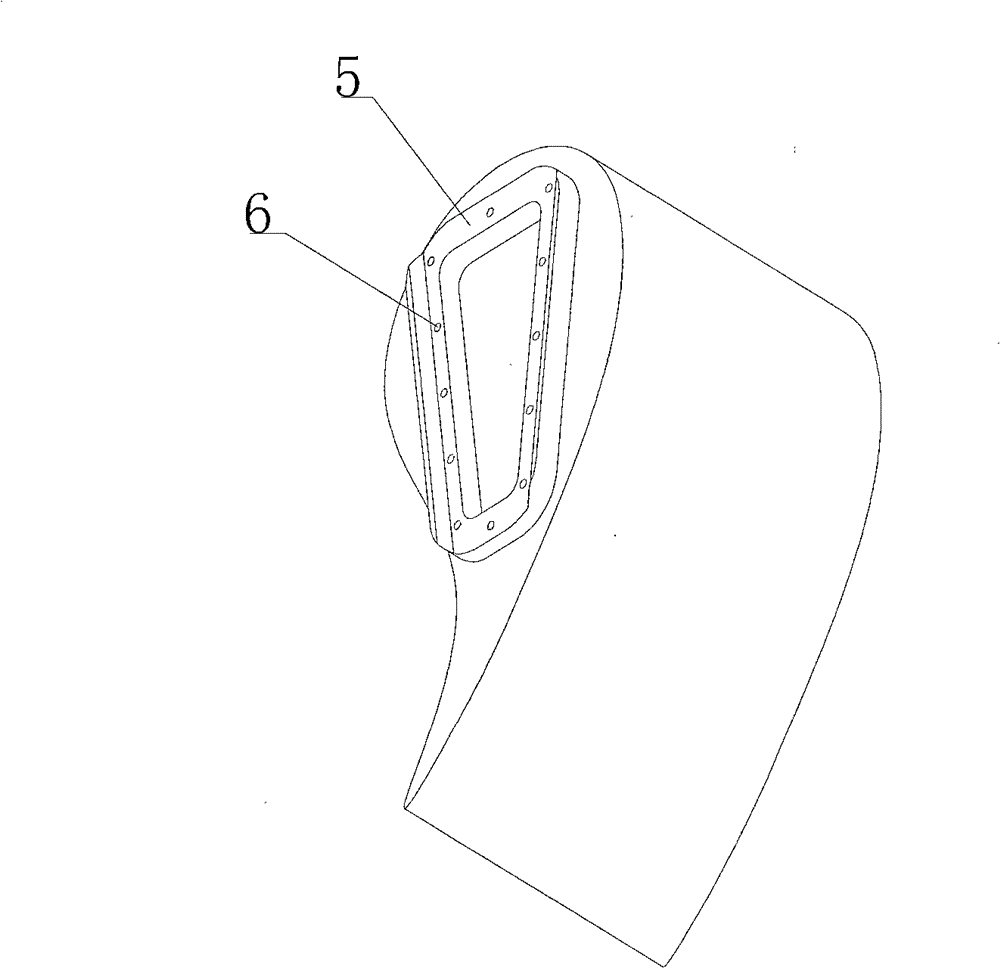

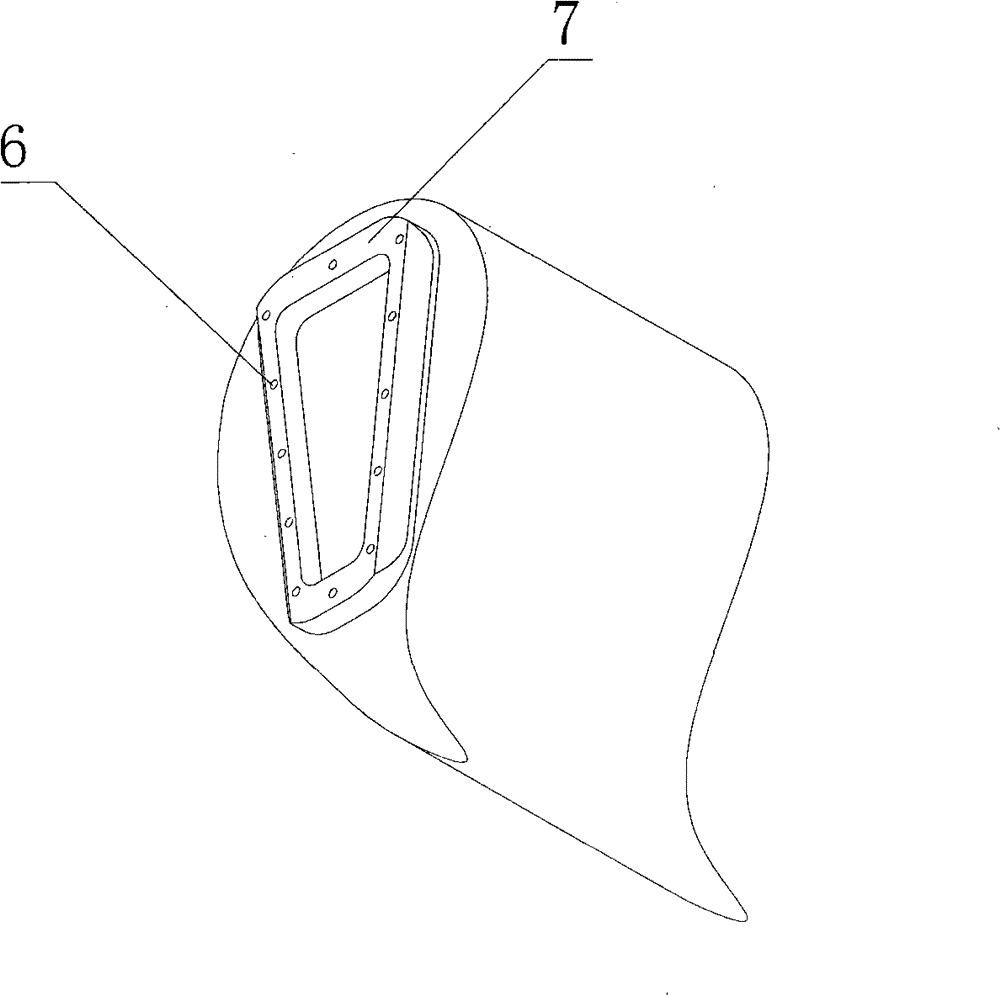

[0026] A segmented assembled fan blade of the present invention comprises a blade body, the blade body is at least divided into two sections each provided with butt joint surfaces, and the butt joint surfaces between adjacent segments of the blade bodies are matched and connected with each other. The two connecting surfaces of the two adjacent blade bodies are respectively provided with a chute 5 and a guide rail 7 matched with the chute 5; when assembled, the guide rail 7 is embedded in the chute 5 and connected Connected by bolt 8.

[0027] Further description will now be given in conjunction with the embodiments and accompanying drawings, taking the sub-blade body divided into three sections as an example.

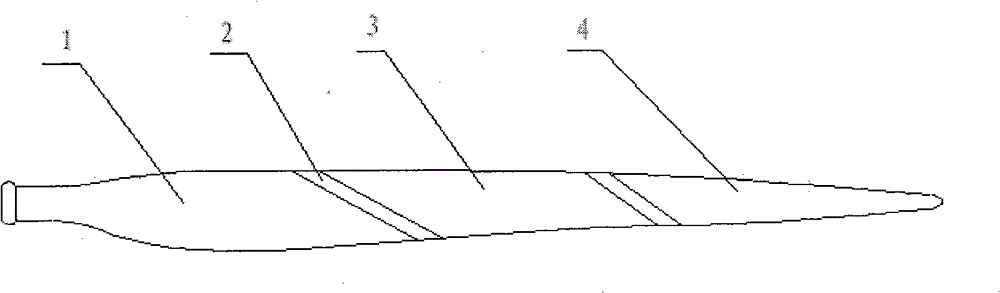

[0028] Such as figure 1 As shown, the blade body is divided into a blade root 1 , a blade middle 3 and a blade top 4 . Such as figure 2 , 3 , 4, and 5, the blade body is hollow, and the inclined surfaces at the ends of two adjacent segments of the blade body are us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com