Double crank shaft horizontal combustion motor with bidirectional piston cylinder

A two-way piston, double crankshaft technology, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problems of limited field, insufficient energy utilization, energy waste, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

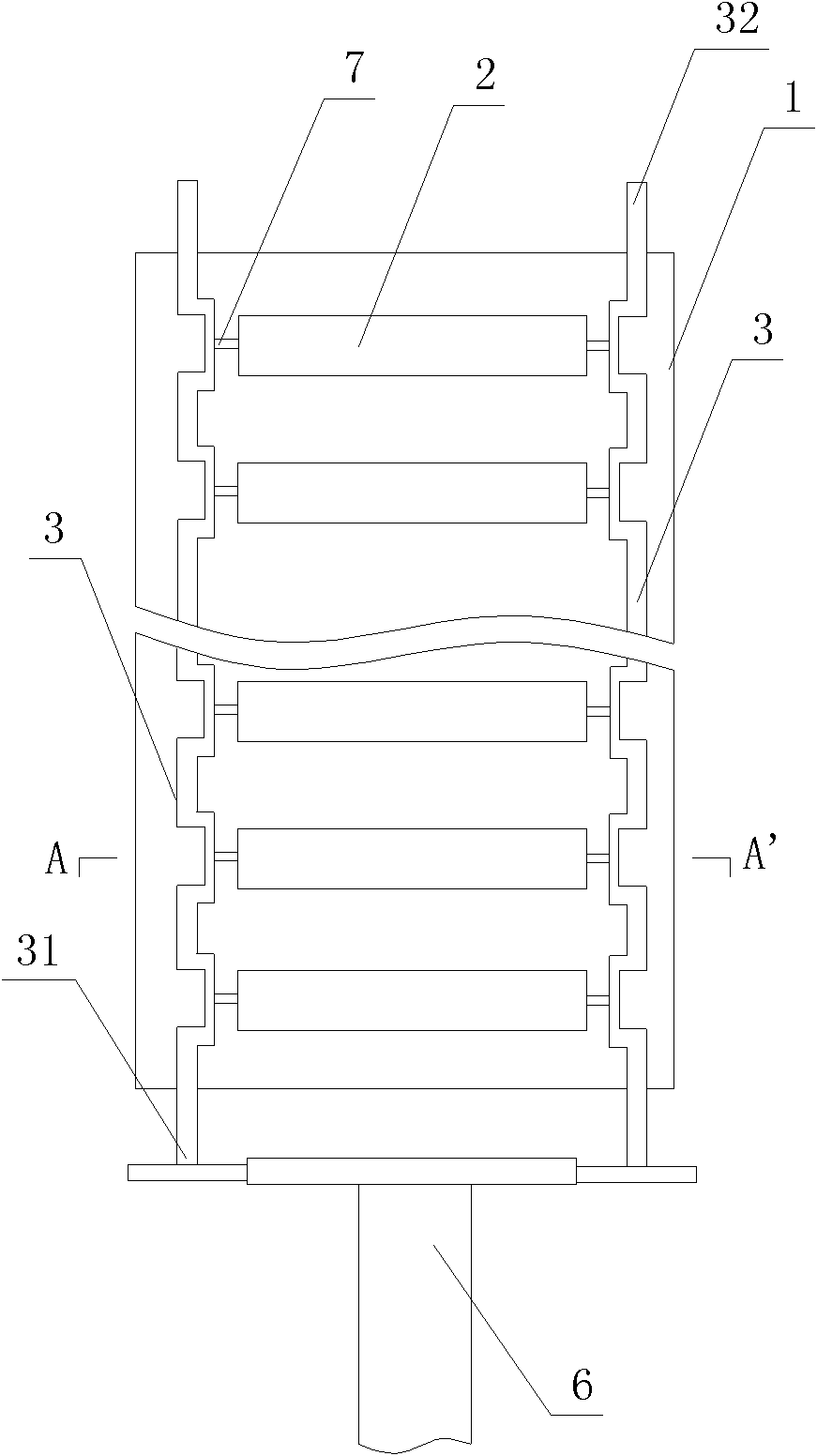

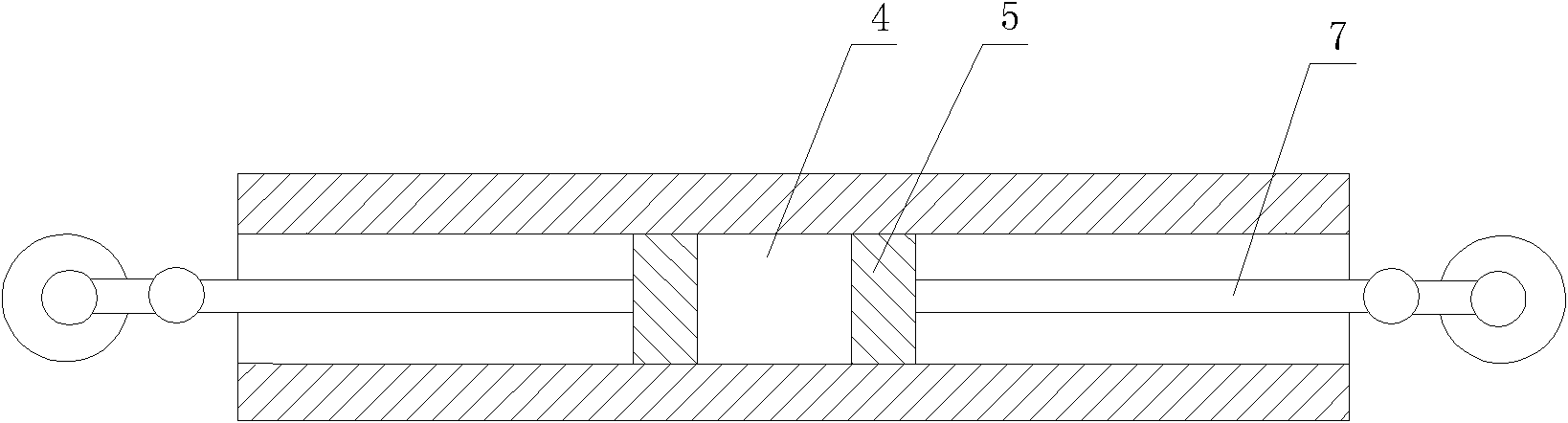

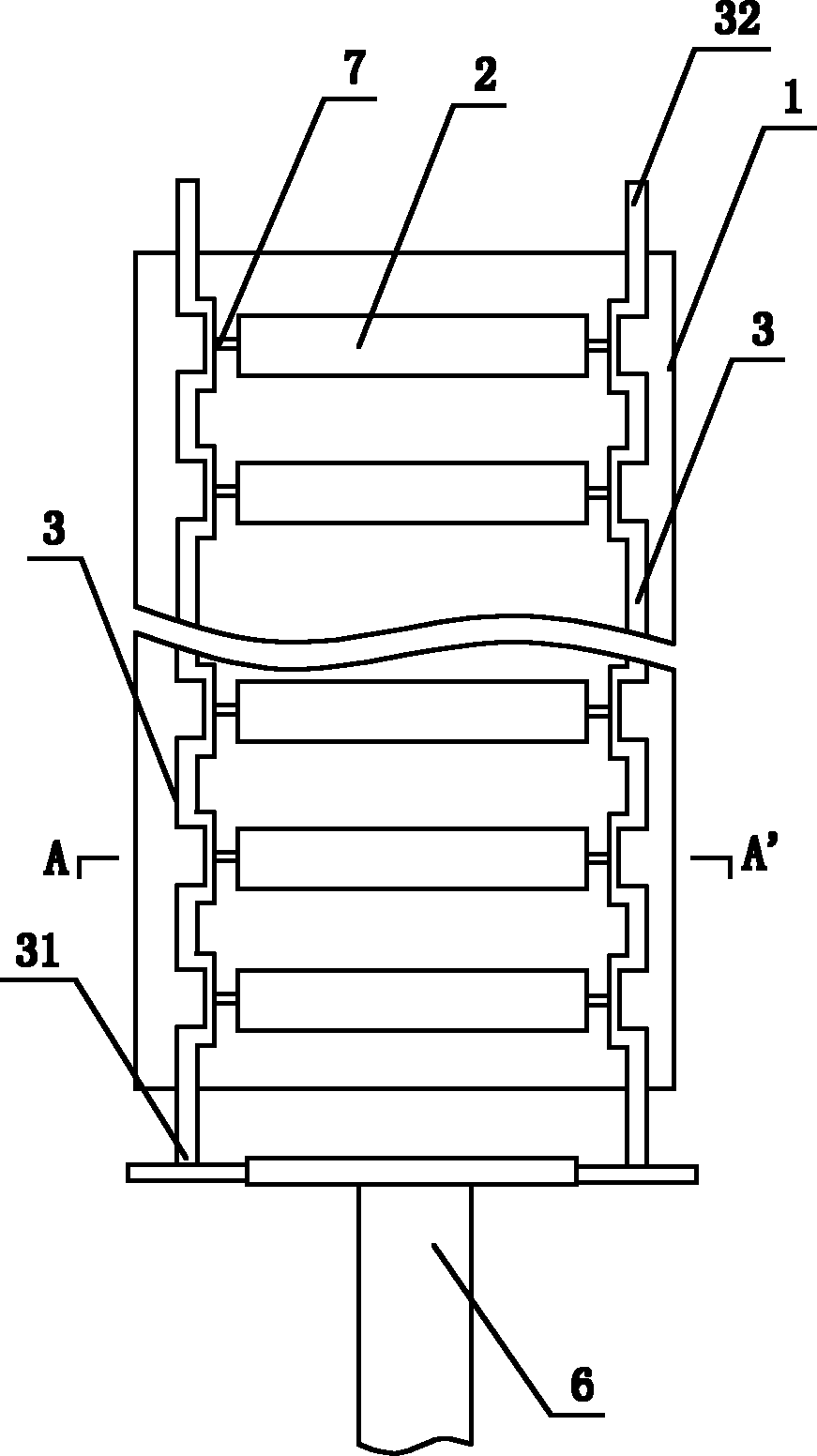

[0018] Such as figure 1 , figure 2 As shown, the double crankshaft internal combustion engine with two-way piston cylinders of the present utility model includes a body 1, a starting device, a lubrication system, a fuel supply system, a cooling system, five cylinder blocks 2 and a crankshaft 3, and the starting device passes through a linkage Fixed on the input end 32 of the crankshaft 3, the crankshaft 3 is set to two, and its output end 31 is connected with the transmission device, the transmission device mainly includes the output shaft 6, and the output shaft 6 is located between the output ends 31 of the two crankshafts 3 And parallel to the crankshaft 3; each cylinder block 2 is installed side by side and flat inside the body 1, and two crankshafts 3 are respectively placed on both sides of the five cylinder blocks 2 installed horizontally; the cylinder block 2 is installed inside There are two mutually symmetrical pistons 5, the pistons 5 are fixed on the rocker arm 7...

Embodiment 2

[0021] Such as figure 1 , figure 2 As shown, the double crankshaft internal combustion engine with two-way piston cylinders of the present utility model includes a body 1, a starting device, a lubrication system, a fuel supply system, a cooling system, five cylinder blocks 2 and a crankshaft 3, and the starting device passes through a linkage Fixed on the input end 32 of the crankshaft 3, the crankshaft 3 is set to two, and its output end 31 is connected with the transmission device, the transmission device mainly includes the output shaft 6, and the output shaft 6 is located between the output ends 31 of the two crankshafts 3 And parallel to the crankshaft 3; each cylinder block 2 is installed side by side and flat inside the body 1, and two crankshafts 3 are respectively placed on both sides of the five cylinder blocks 2 installed horizontally; the cylinder block 2 is installed inside There are two mutually symmetrical pistons 5, the pistons 5 are fixed on the rocker arm 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com