Marbleized rotational moulding special material and preparation method thereof

A technology of imitating marble and special materials, applied in the field of special materials for rotomolding and its preparation, can solve the problems of inconsistent particle size distribution on the inner and outer surfaces, uneven distribution of marble particles, and flowery particles, and achieves a beautiful appearance, broad market prospects, The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

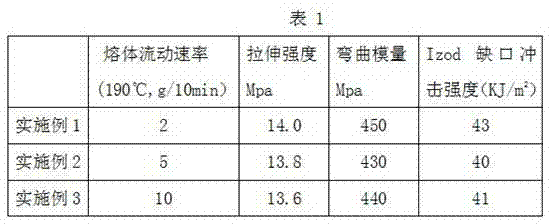

Examples

Embodiment 1

[0018] The linear low density polyethylene of the present embodiment: melt flow rate 2g / 10min, density 0.925g / cm 3 ;High-density polyethylene: melt flow rate 0.01g / min, density 0.950 g / cm 3 ;

[0019] Formula: A, 63.5% by mass percentage of linear low density polyethylene;

[0020] B, gray particles with a mass percentage of 24%;

[0021] C, white particles with a mass percentage of 8.5%;

[0022] D. Black particles with a mass percentage of 4%.

[0023] The preparation method proceeds as follows:

[0024] ⑴Basic resin treatment

[0025] The linear low-density polyethylene R901U is ground into a powder in a plastic milling machine, and the particle size analyzer is measured and analyzed. The distribution of the powder: the geometric average particle size D is 0.5mm, and the particle size dispersion index The value is 0.3. The grinding process is as follows: 30 mesh screen, 60 mesh gap between grinding discs, and 3000 rpm rotation speed.

[0026] ⑵Imitation marble powd...

Embodiment 2

[0034] The linear low density polyethylene of the present embodiment: melt flow rate 5g / 10min, density 0.930g / cm3 ;High-density polyethylene: melt flow rate 0.75g / 10min, density 0.956 g / cm 3 ; Formula: A, 40% by mass percentage of linear low density polyethylene;

[0035] B, the green particle of 40% by mass percentage;

[0036] C. White particles with a mass percentage of 20%.

[0037] The preparation method proceeds as follows:

[0038] ⑴Basic resin treatment

[0039] The linear low-density polyethylene is ground into a powder in a plastic mill, and the control process makes the powder distribution composition: the geometric average particle size D is 0.42mm, and the particle size dispersion index The value is 0.2. The grinding process is as follows: 30 mesh screen, 70 mesh gap between grinding discs, and 4000 rpm rotation speed.

[0040] ⑵Imitation marble powder manufacturing

[0041] Manufacturing of green granules: Mix 98% high-density polyethylene, 1% green powder...

Embodiment 3

[0048] The linear low density polyethylene of the present embodiment: melt flow rate 9.5g / 10min, density 0.940g / cm 3 ;High-density polyethylene: melt flow rate 2g / 10min, density 0.960g / cm 3 ; Formula: A, 62% linear low density polyethylene by mass percent;

[0049] B, gray particles with a mass percentage of 22%;

[0050] C, white particles with 9% mass percentage;

[0051] D, the red particle of 4% by mass percentage;

[0052] E. Black particles with a mass percentage of 3%.

[0053] The preparation method proceeds as follows:

[0054] ⑴Basic resin treatment

[0055] Grind linear low-density polyethylene into a powder in a plastic mill, powder distribution: geometric mean particle size D is 0.45mm, particle size dispersion index The value is 0.5. The grinding process is: 30 mesh screen, 80 mesh gap between grinding discs, 5000 rpm;

[0056] ⑵Imitation marble powder manufacturing

[0057] Manufacturing of gray granules: Mix 98% high-density polyethylene, 0.1% gray po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com