Heavy duty pneumatic tire

一种充气轮胎、轮胎的技术,应用在重型轮胎、充气轮胎的增强层、轮胎零部件等方向,能够解决胎体帘线断裂等问题,达到提高耐久性的效果

Active Publication Date: 2011-04-13

SUMITOMO RUBBER IND LTD

View PDF5 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the pneumatic tire for heavy duty is used under a high internal pressure and a high load, and as a result, breakage of the carcass cord (hereinafter, simply referred to as "CBU") tends to occur.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

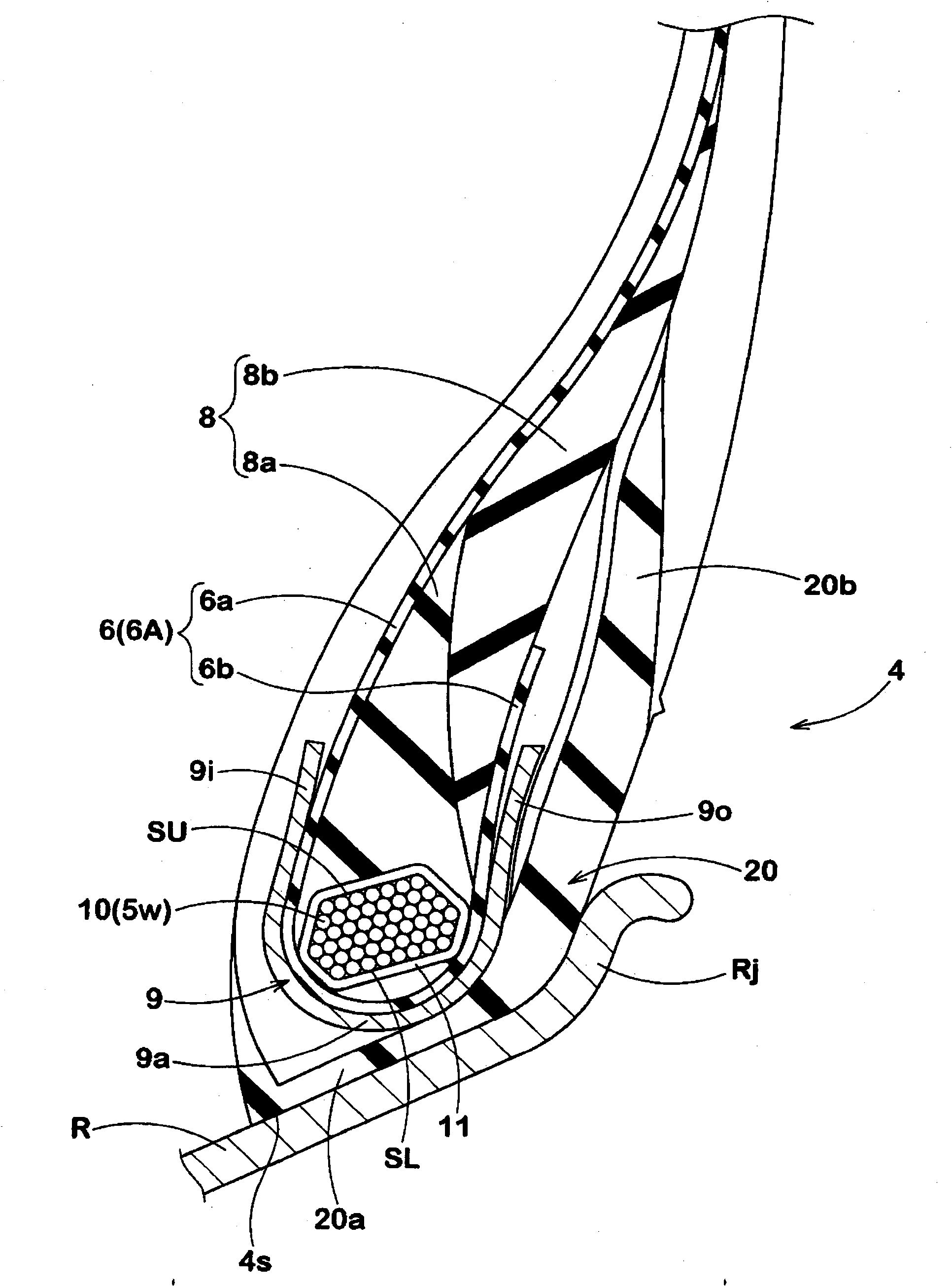

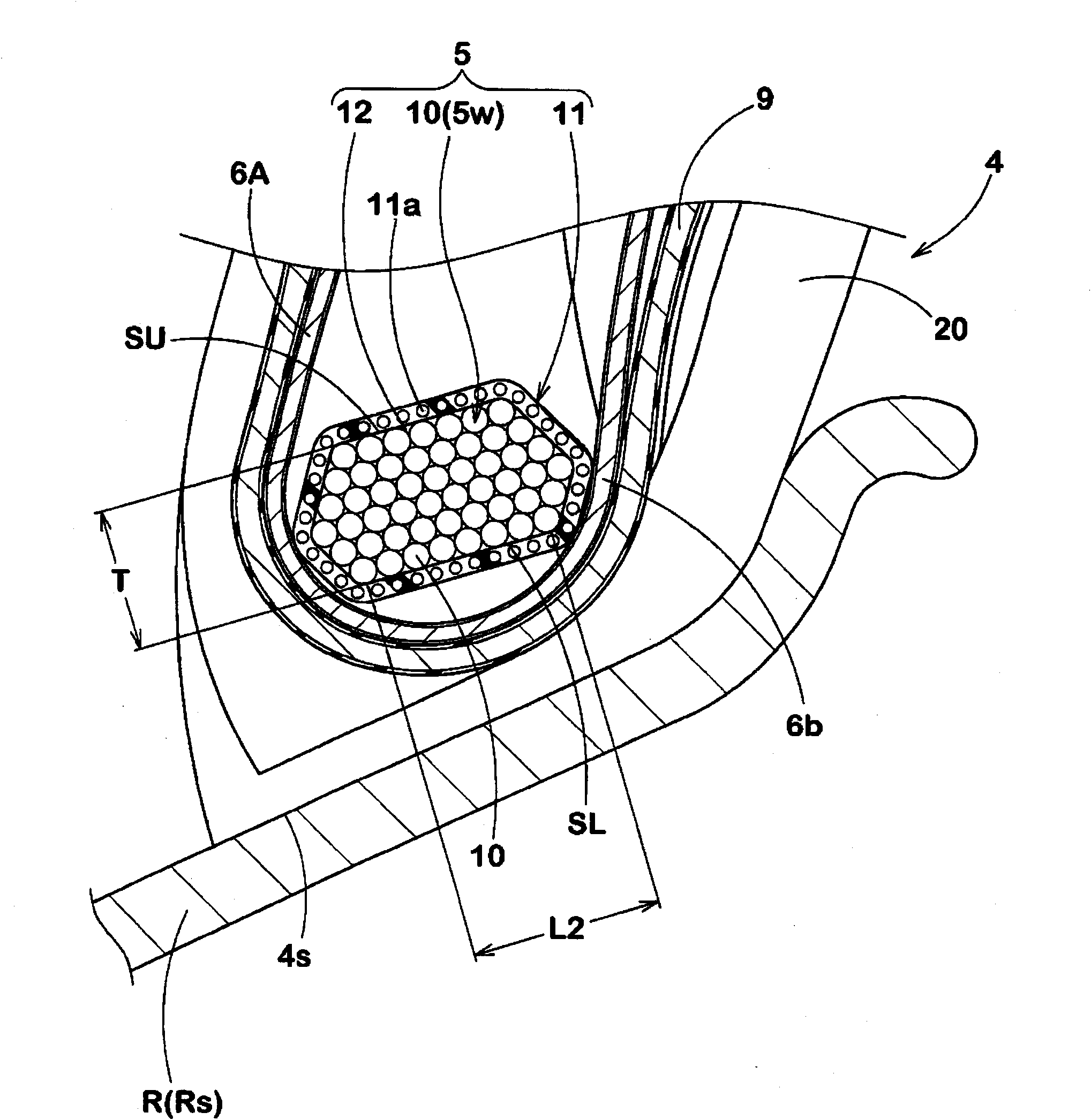

[0052] Based on the specifications in Table 1 figure 1 The tire structure shown is a 385 / 65R22.5 pneumatic tire for heavy duty trucks, and the following brake drum driving test was performed. Except for the specifications in Table 1, they are essentially the same specifications.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a heavy duty pneumatic tire, which prevents CBU of the carcass ply and improves the service durability of the bead portion. The steel cords of the carcass ply are rubberized with a topping rubber having a hardness Ht1 of from 68 to 90 degrees. The bead core is composed of: a bead core main made of windings of a steel wire; a rubber coating penetrating into the bead core main and having a hardness Hb of from 78 to 90 degrees; and a bead core wrapping layer surrounding the bead core main and composed of at least one ply of parallel organic fiber cords rubberized with a topping rubber having a hardness Ht2 of from 70 to 90 degrees. The fineness of each of the organic fiber cords of the bead core wrapping layer is in a range of from 940 to 4200 dtex. The distances between the organic fiber cords of the bead core wrapping layer is in a range of from 0.3 to 1.4 mm. The organic fiber cords of the bead core wrapping layer are inclined at an angle in a range of from 20 to 70 degrees with respect to the tire circumferential direction.

Description

Technical field [0001] The present invention relates to a pneumatic tire for heavy duty trucks that improves the durability of the bead portion by preventing CBU (Cord Broken Up) of the carcass cord. Background technique [0002] Generally, pneumatic tires for heavy-duty trucks and buses used in trucks and buses are reinforced with carcass cords that pass from the tread portion to the sidewall portion and surround the bead core embedded in the bead portion from the inner side to the outer side of the tire axial direction. Made of folded steel cords. [0003] However, heavy-duty pneumatic tires are used under high internal pressure and high load, and as a result, the carcass cord is likely to break (hereinafter, simply referred to as "CBU"). After investigating the locations where such CBUs occur, the inventor found that most CBUs are caused by carcass cords extending near the innermost side of the bead core in the tire axial direction. [0004] In order to prevent such CBU of carca...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B60C15/04B60C15/06

CPCB60C2200/06B60C2015/048B60C15/04B60C2009/0276B60C2015/044Y10T152/10819Y10T152/10864Y10T152/10846

Inventor 山崎和美

Owner SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com