Clamping apparatus of live line tools

A live working and clamping technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of insufficient universality of line fittings and connecting plates, insufficient gap distance of insulation combination, endangering the safety of construction workers, etc., and achieves simple structure, safe and reliable use. , The effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

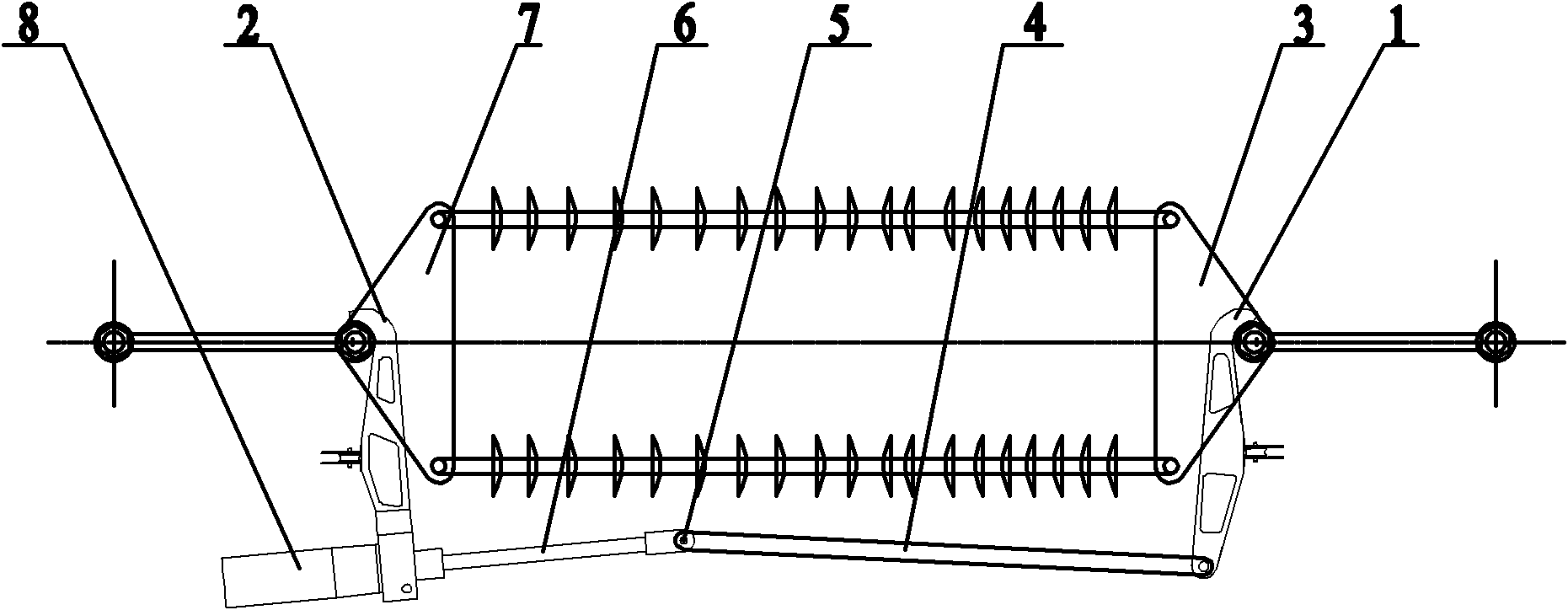

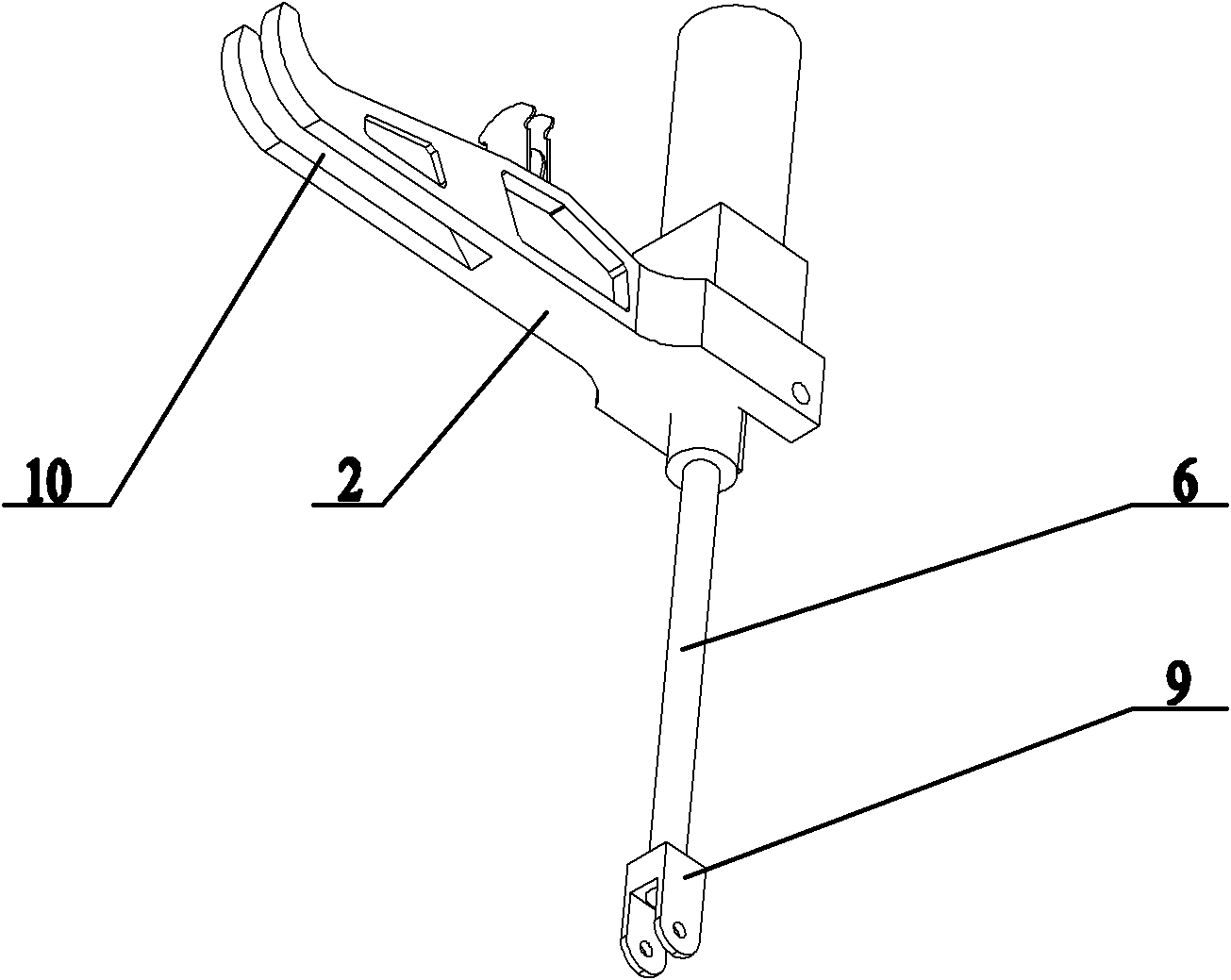

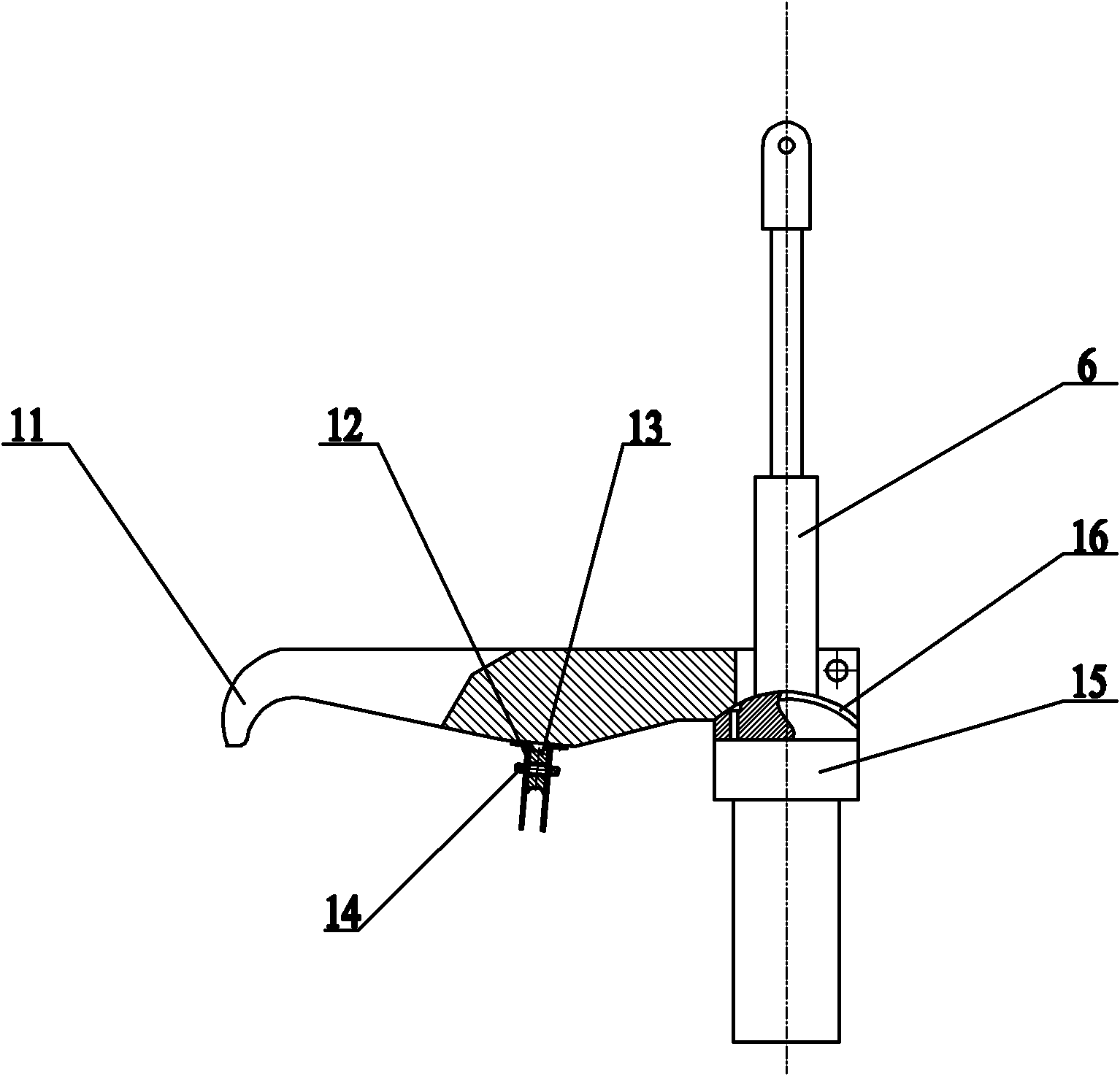

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0021] Such as Figure 1~Figure 7 As shown: the present invention includes a front fixture 1, a rear fixture 2, a first fitting triangular plate 3, an insulating drawing rod 4, a hinged shaft 5, a hydraulic stretching rod 6, a second fitting triangular plate 7, a hydraulic load-bearing tool 8, Connecting head 9, second installation groove 10, second bending part 11, rear fixture lifting pulley mounting piece 12, rear fixture lifting pulley 13, rear fixture lifting pulley main shaft 14, hydraulic cylinder slider 15, positioning part 16, Connecting chute 17, third mounting groove 18, first bending portion 19, weight reduction groove 20, front fixture lifting pulley 21, connecting hole 22, front fixture lifting pulley main shaft 23, front fixture lifting pulley mounting piece 24, The first mounting slot 25 and the front clip connecting slot 26 .

[0022] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com