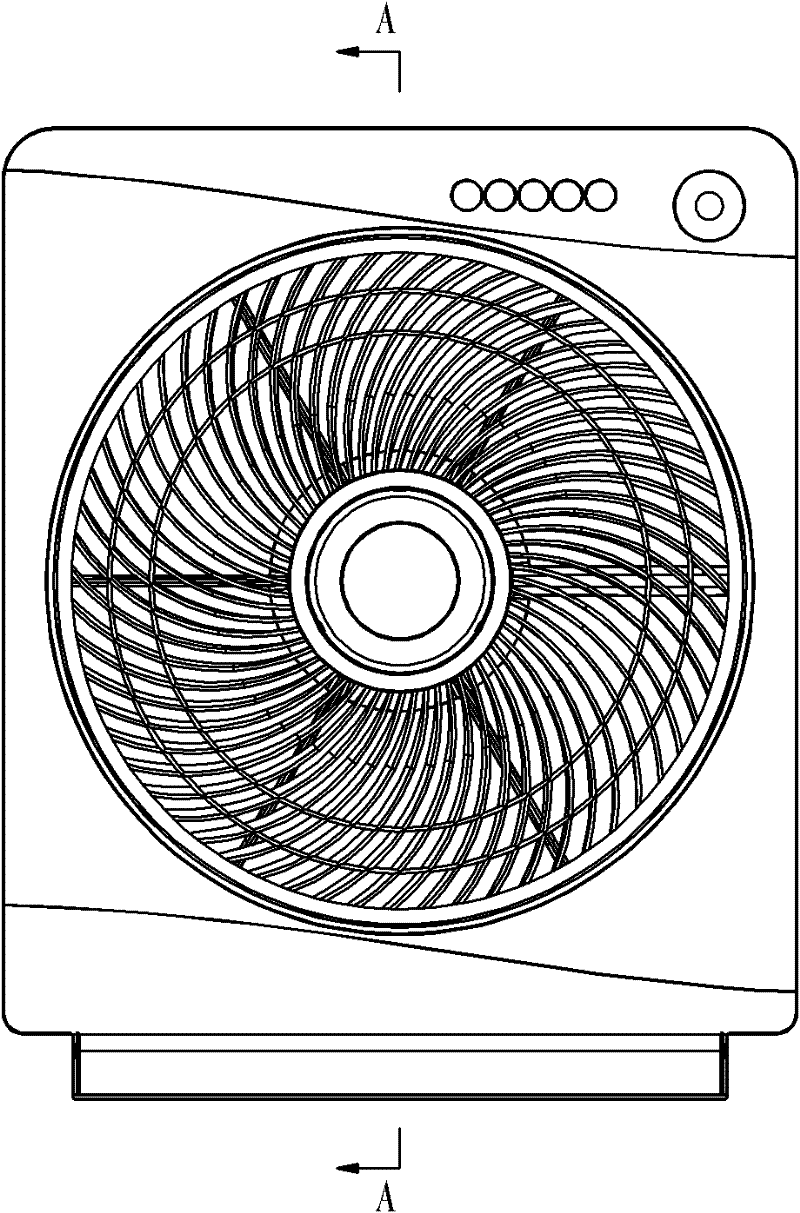

Air guide mechanism of box fan

A technology of air guiding mechanism and leaf turning fan, which is applied in the field of turning leaf fans, which can solve the problems of unreliable fixing method of wind guiding wheel, many parts, complicated assembly, etc., and achieve convenient and quick installation, reduced parts and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

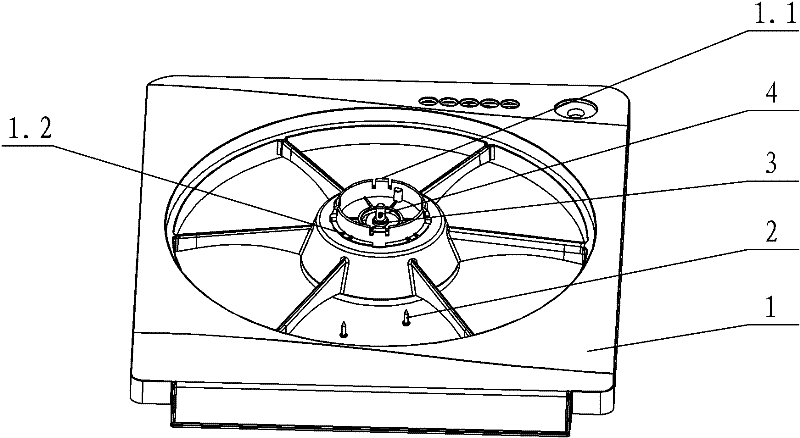

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

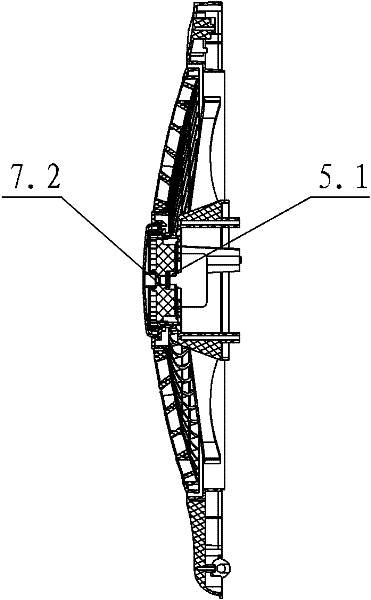

[0027] see Figure 1-Figure 2 , the air guide mechanism of the leaf turning fan, including the synchronous motor 3 arranged on the casing 1, the rotating shaft pin 4 arranged on the synchronous motor 3, the wind guide wheel clutch plate 5, the wind guide wheel 6 and the wind guide wheel cover 7 The shell 1 is provided with two or more buckle positions 1.1 towards the wind guide wheel 6, the inner side of the wind guide wheel 6 is provided with a wind guide wheel inner ring 6.1, and the buckle positions 1.1 are hooked on the wind guide wheel inner ring 6.1. The buckle 1.1 is in clearance fit with the inner ring 6.1 of the wind deflector wheel. The gap is 0.2-0.5mm. There are four buckle positions 1.1 in this embodiment.

[0028] More than two ribs 1.2 are arranged on the outer edge of the buckle 1.1 on the shell 1, and the ribs 1.2 lean against the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com