Static sounding device and static sounding testing method

A static penetration and test method technology, applied in the field of geotechnical engineering investigation, can solve problems such as low efficiency and time-consuming, and achieve the effects of reducing equipment, saving equipment costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

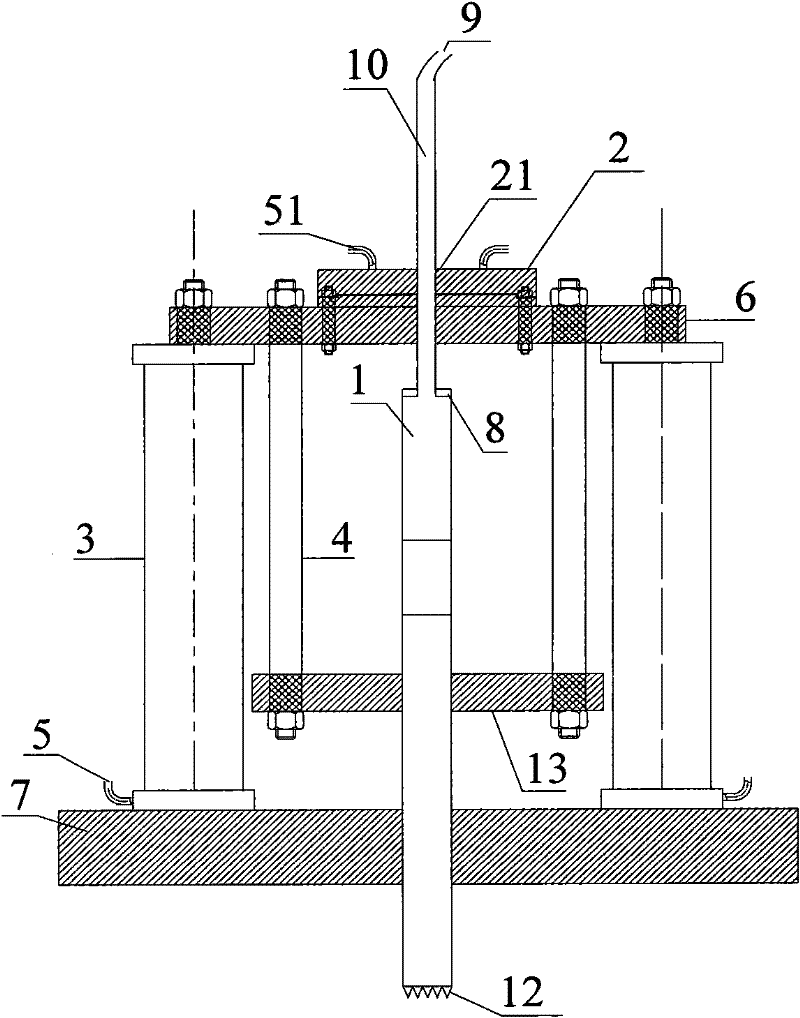

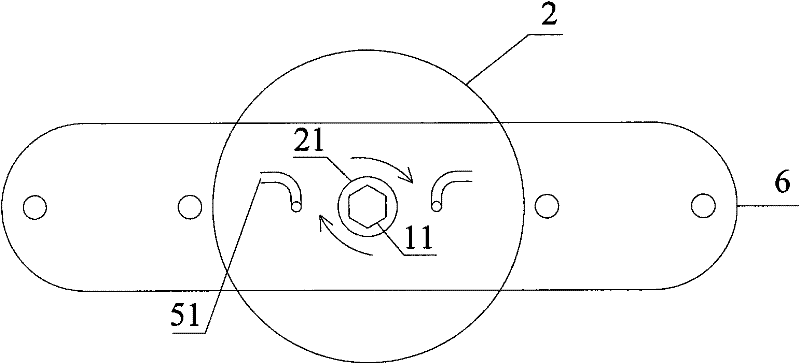

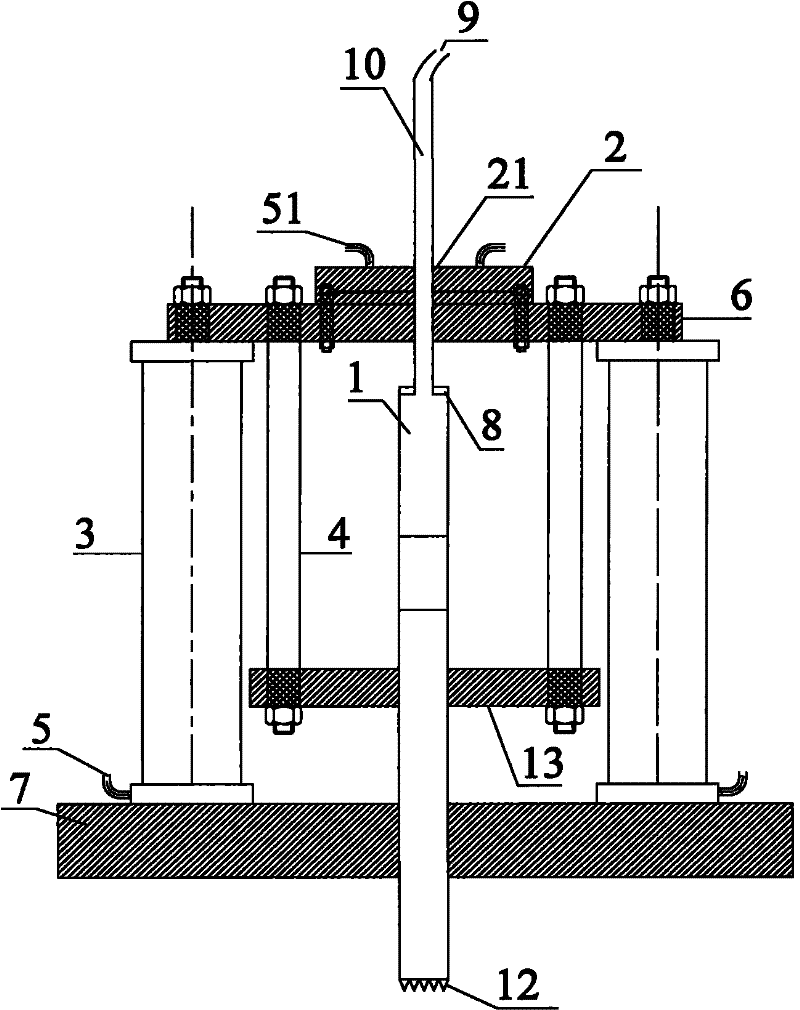

[0030] Such as figure 1 Shown is a schematic structural view of the static penetration penetrating equipment of the present invention. The static penetration testing equipment includes a static penetration testing machine, the static penetration testing machine is provided with a ground beam 7, and two hydraulic cylinders 3 installed on the ground beam 7 are fixedly connected between the tops of the two hydraulic cylinders 3 The crossbeam 6 is fixedly provided with two downwardly protruding columns 4 on the crossbeam 6, and a stabilizing beam 13 is connected between the ends of the two columns 4, and a driving device 2 is arranged on the top of the crossbeam 6, and the driving device 2 is a kind of The hydraulic motor is provided with two oil pipes 51, and the turntable 21 is a rotating part of the hydraulic motor. The center of rotating disk 21 is provided with hexagonal through hole 11 (seeing figure 2 ). The protective pipe assembly 1 includes several sections of protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com