False twist texturing machine

A processing machine and false twisting technology, applied in textiles and papermaking, etc., can solve problems such as difficulty in securing space and poor workability, and achieve the effects of securing work space, reducing stress and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described below. In this embodiment, a false twist processing machine for producing a highly stretchable processed yarn by applying false twist to a thermoplastic synthetic fiber such as polyester or polyamide to provide crimp will be described.

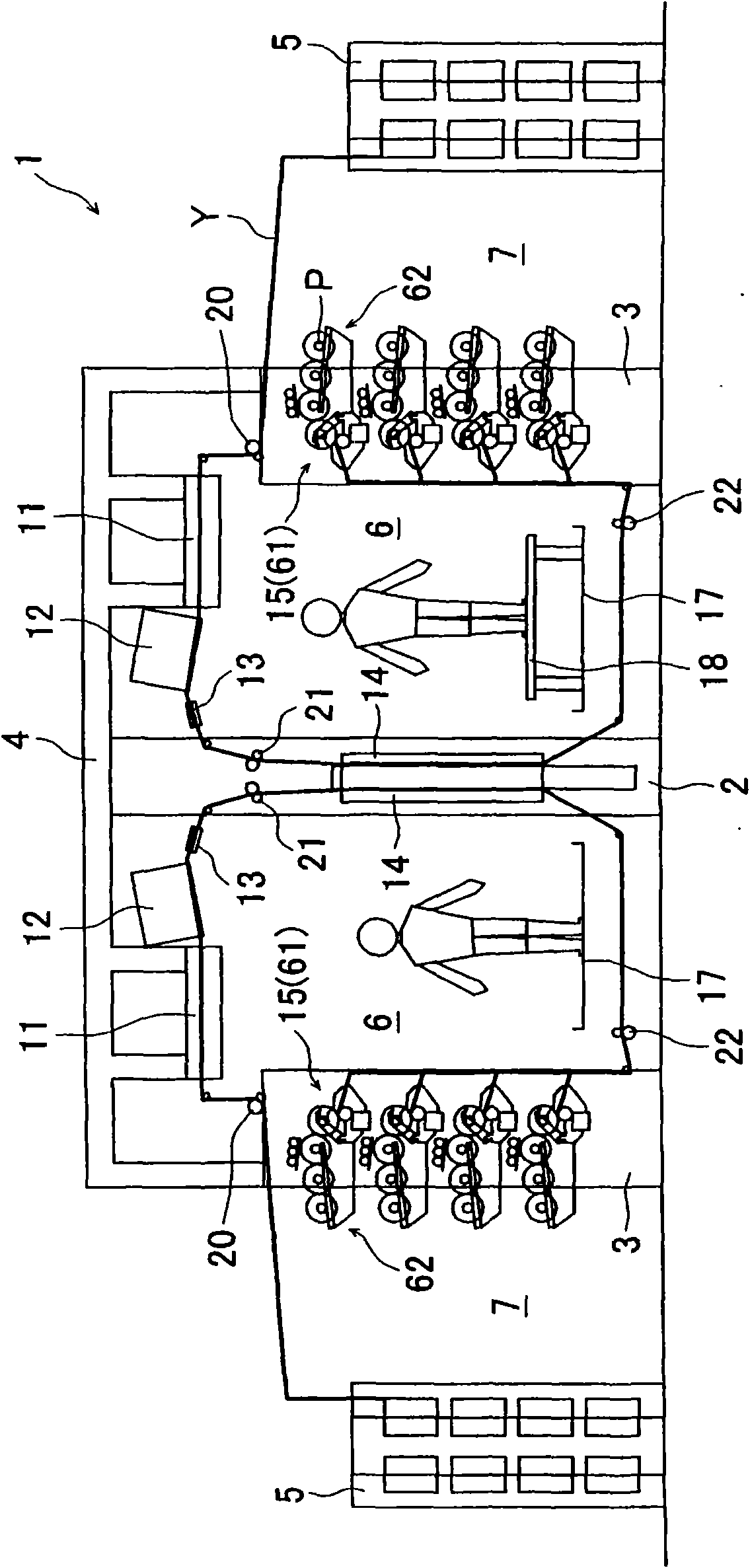

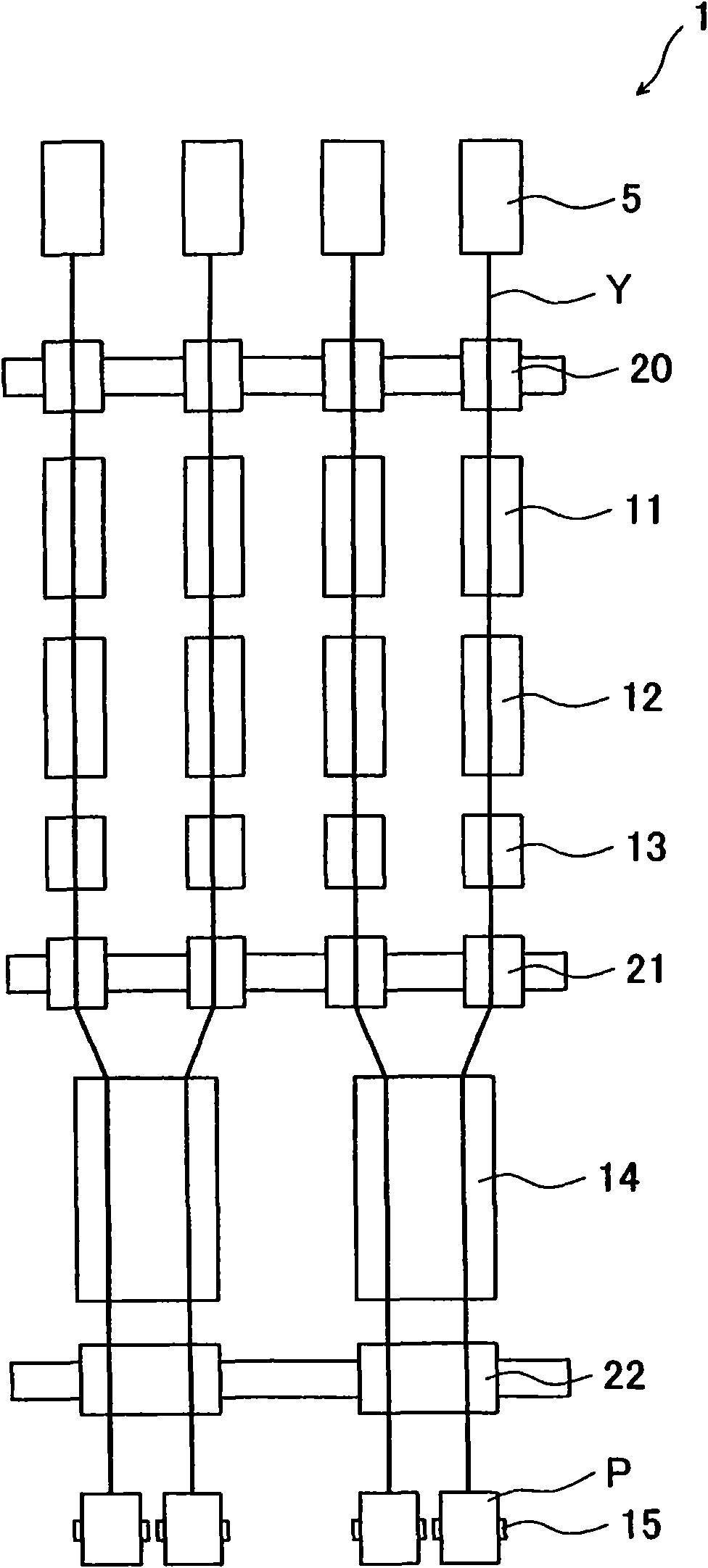

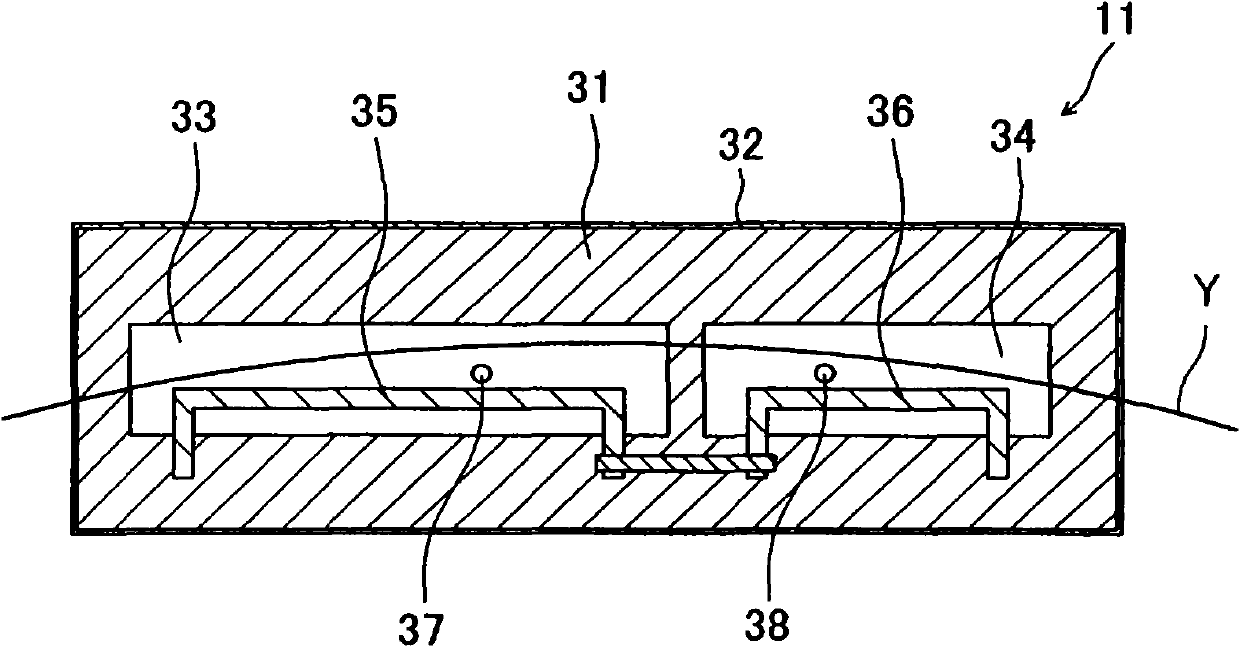

[0026] First refer to figure 1 The general structure of the false twist processing machine will be described. Such as figure 1 As shown, the false twist processing machine 1 has a main body 2 extending in the vertical direction and two winding seats 3. The two winding seats 3 are separated from the working space 6 and are respectively arranged on the main body 2 opposite to the main body 2. at an axisymmetric position for the axis. On the side opposite to the working space 6 of the winding base 3, there is a space 7 for the worker to take the fully wound package P that has been wound by a winding device 15 described later installed on the winding base 3. . In addition, the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com