Pneumatic tire

A technology of pneumatic tires and bead parts, which is applied to the reinforcement layers, tire parts, wheels, etc. of pneumatic tires, can solve the problems of reducing rolling resistance and increasing tire volume, and achieves reducing rolling resistance, reducing tire deformation, suppressing The effect of belt wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

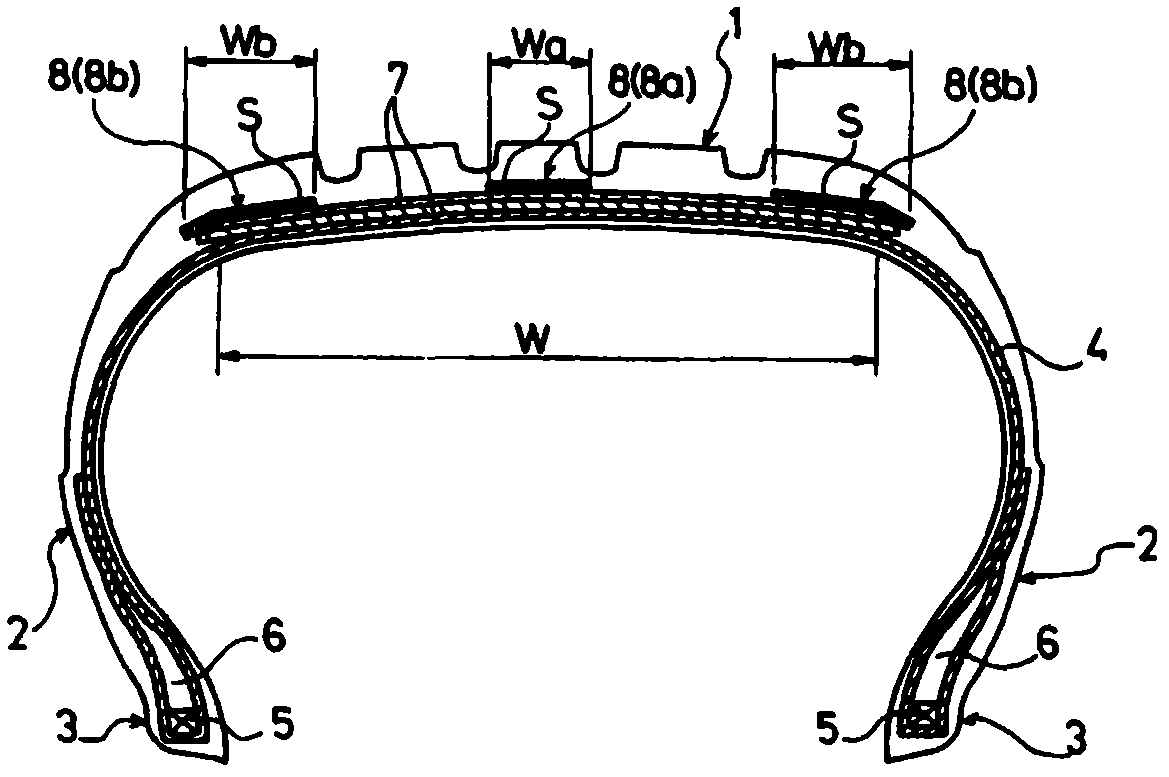

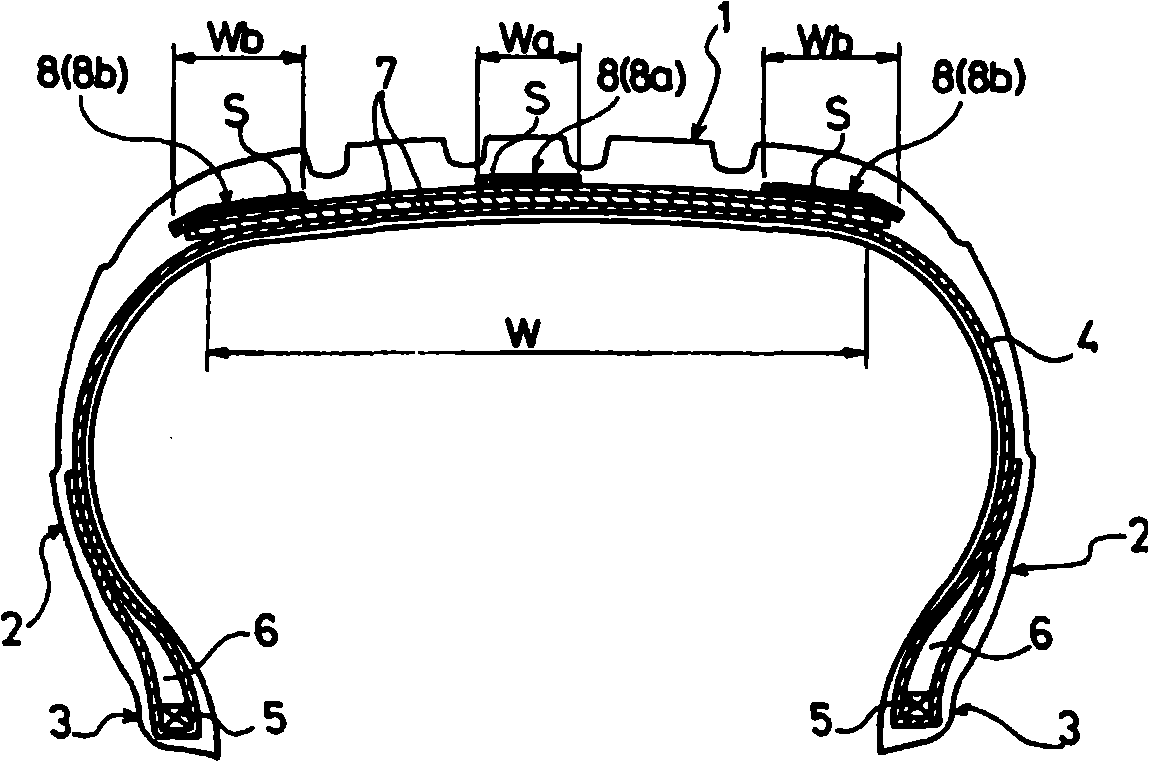

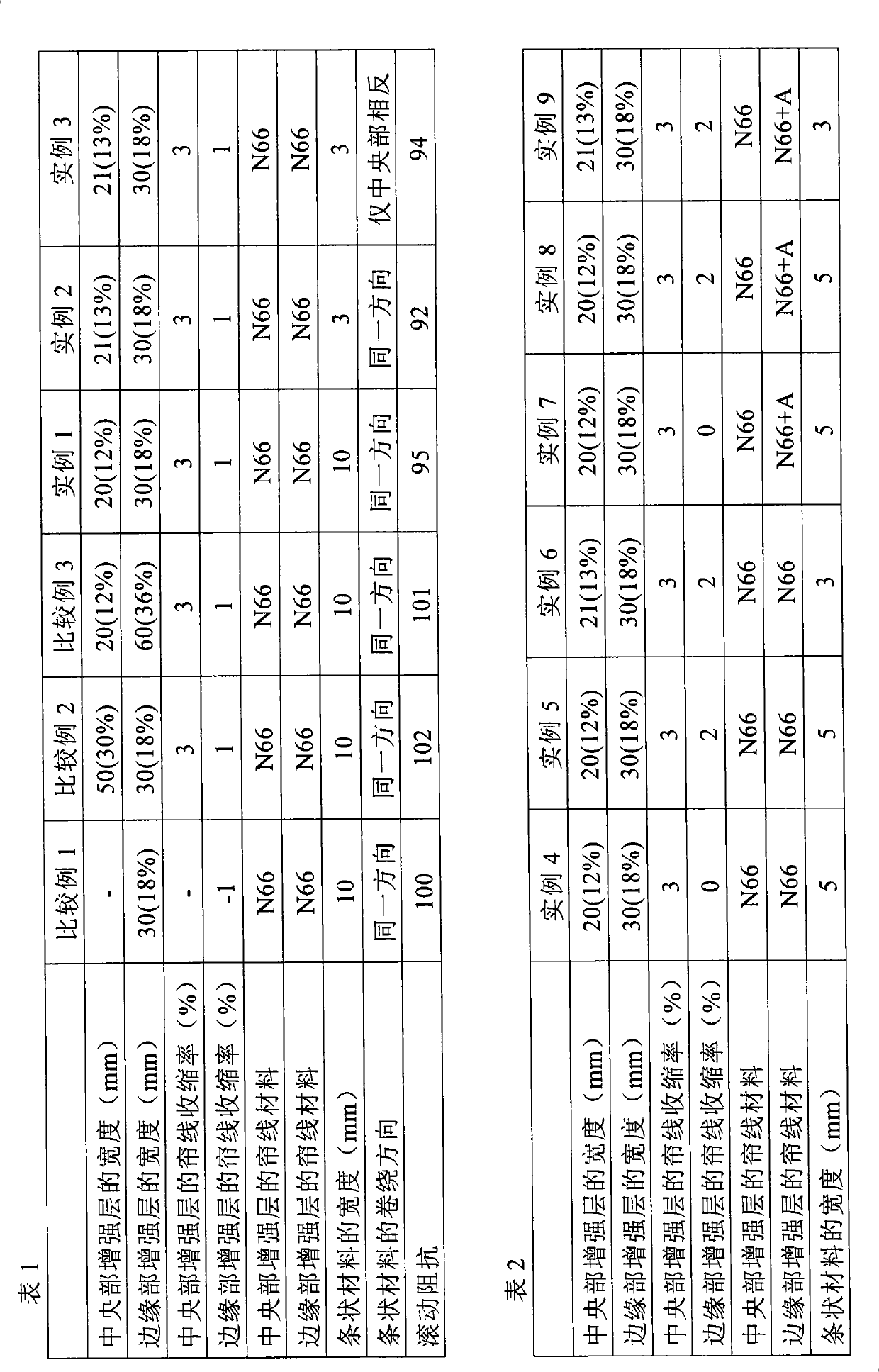

[0036] Pneumatic tires of Comparative Examples 1 to 3 and Examples 1 to 9 were produced, the tire size of which was 195 / 65R15, a carcass was provided between a pair of bead parts, and two belt layers were arranged on the outer peripheral side of the carcass of the tread part, And on the outer peripheral side of these belt layers, a belt reinforcing layer formed by spirally winding a strip-shaped material including at least one fiber cord in the tire circumferential direction is arranged, wherein the belt reinforcing layer is composed of The central reinforcement layer and the edge reinforcement layer are composed, and the widths of the central reinforcement layer and the edge reinforcement layer are set as shown in Table 1 and Table 2, and the fiber cords of the central reinforcement layer and the edge reinforcement layer are taken out from the tire. The shrinkage rate, the material of the fiber cords of the central reinforcement layer and the edge reinforcement layer, the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com