Box-type dust collecting device

A dust-collecting device and box-type technology, applied in the field of separation, can solve the problems of low efficiency and poor dust-collecting effect, and achieve the effects of convenient and simple operation, improved filtering effect, and improved dust-collecting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

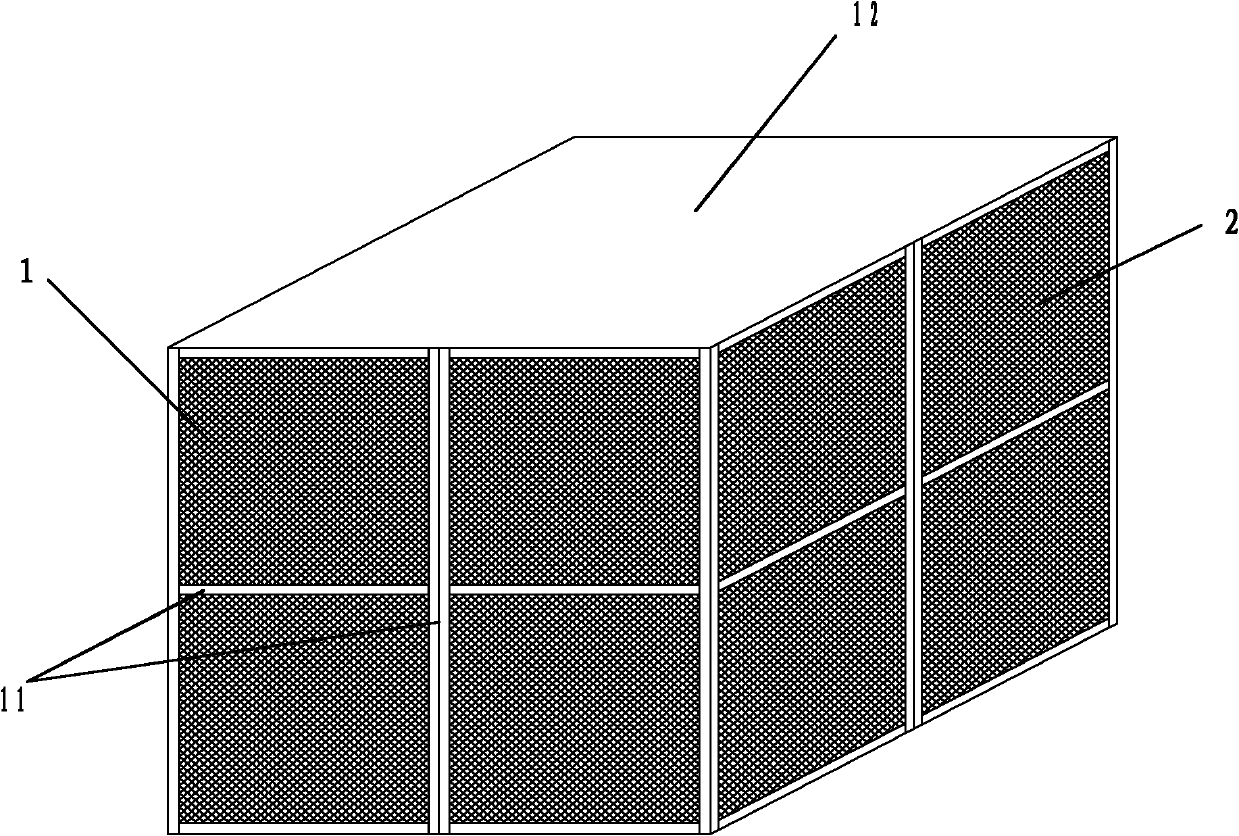

[0029] figure 1 It is a schematic structural diagram of a box-type dust collection device provided in the embodiment of the present application.

[0030] like figure 1 As shown, the box-type dust collection device includes: a support 1, a vertical plate 2 fixed on the side of the support 1 and a filter cotton (not shown in the figure) fixed on the vertical plate 2 .

[0031] like figure 1 As shown, the bracket 1 is a three-dimensional rectangle, and its top 11 is an integral plate, which seals the top. The bottom of the bracket 1 is not sealed and is left as an opening. The side of the support 1 is a plurality of support bars 12, and the four sides of the support 1 are divided into multiple pieces by the plurality of support bars 12. In the embodiment of the present application, the support bars 12 evenly divide each side of the support 1 into four pieces. piece.

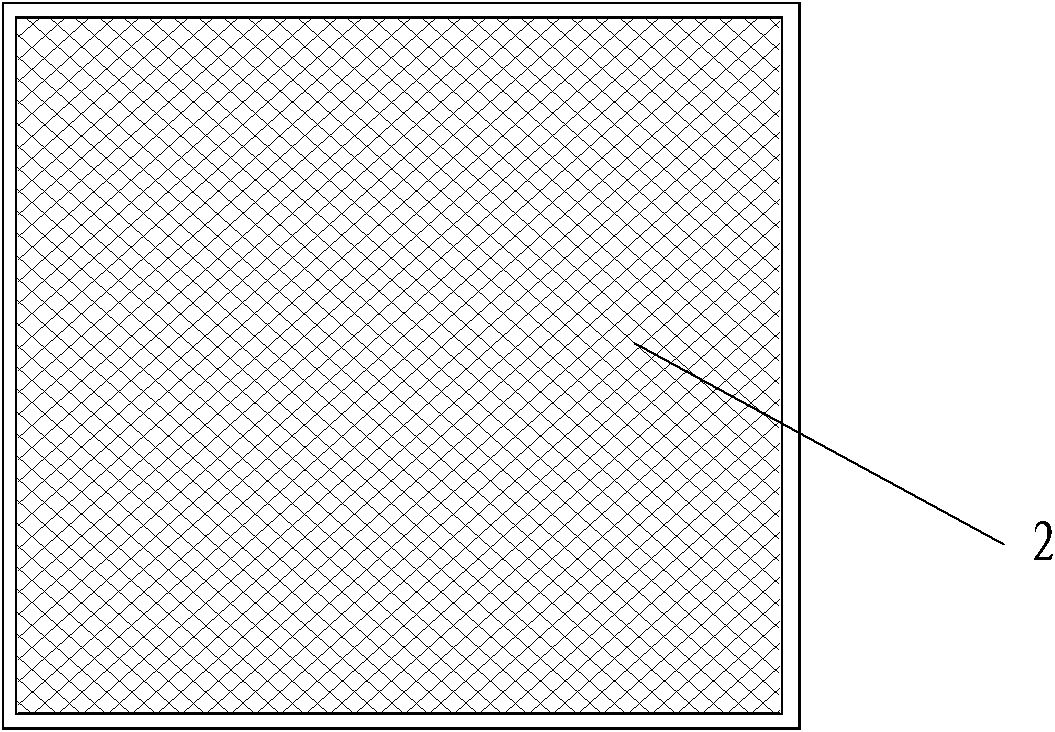

[0032] like figure 1 As shown, the vertical plate 2 is installed on the support rod 12 of the support 1, an...

Embodiment 2

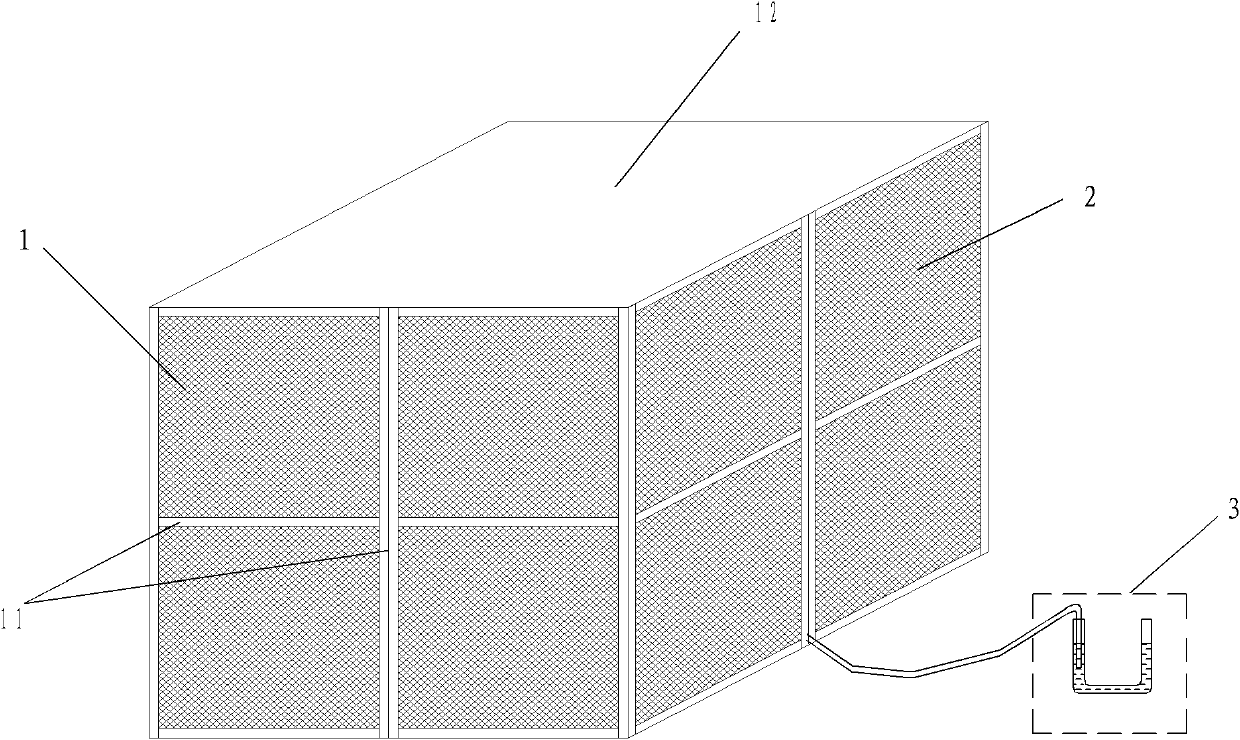

[0036] image 3 It is a schematic structural diagram of another box-type dust collection device provided in the embodiment of the present application.

[0037] like image 3 As shown, the box-type dust collection device also includes: a pressure measuring device (not shown in the figure) and a pressure indicating device 3, wherein:

[0038] The pressure measuring device is located inside the support 1 and is used to measure the gas pressure inside the support 1 . The pressure indicating device 3 is located outside the bracket 1 and is connected with the pressure measuring device to display the measurement results of the pressure measuring device.

[0039] When the box-type dust collection device is working, if it is blocked, its internal pressure will inevitably increase. It will be measured by the pressure measuring device and displayed on the pressure display device, so that the operator can know the box-type dust collector in time. Whether the dust device is blocked.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com