Grounding structure

A technology of grounding structure and contact piece, which is applied to the rack/frame structure, circuit layout on the support structure, cooling/ventilation/heating transformation, etc., which can solve the left and right deviation of the circuit board installation and the inability of the circuit board to be fully integrated Grounding and other issues, to achieve the effect of simple structure, stable grounding performance, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

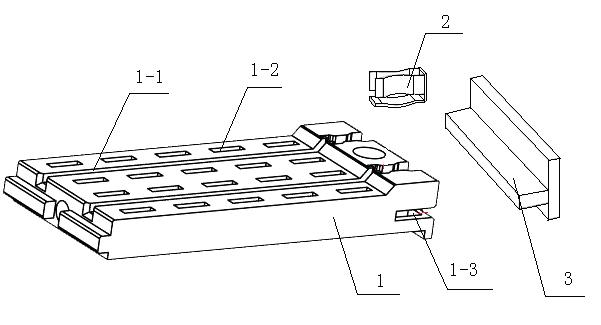

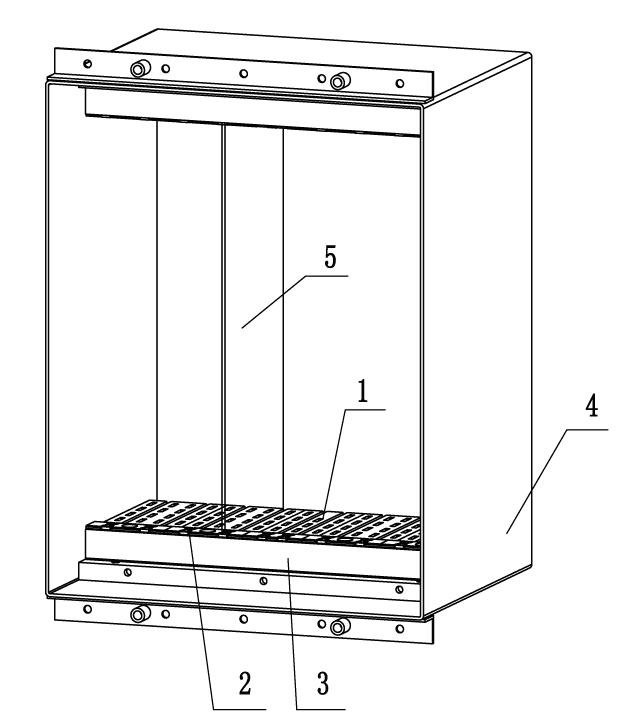

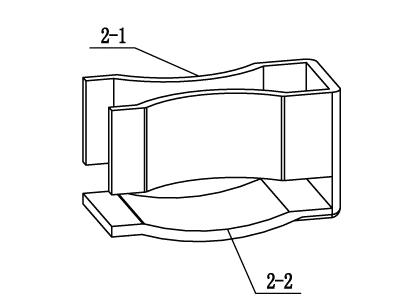

[0014] Such as Figure 1-3 As shown, a grounding structure includes a casing 4, a T-shaped metal bracket 3 located in the casing 4, and a guide block 1; 1-1, and the slot 1-3 matching the T-shaped tail of the metal bracket 3, the guide groove 1-1 runs through the upper surface of the guide groove block 1 along the axial direction of the guide groove block 1, and the slot 1-3 is located in the guide groove The end of the block 1, which communicates with the guide groove 1-1 and is located below the guide groove 1-1; the fixed clip 2 is provided with a U-shaped clip 2-1 and a contact piece 2-2, and the two clips 2-1 The arm is arc-shaped and relatively inwardly protruding, the bottom of the clip 2-1 is attached to the inner wall of the T-shaped head of the metal bracket 3, the contact piece 2-2 is connected to the bottom of the clip 2-1 and is located at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com