Cooler of heat pipe type wind generating set

A technology for wind turbines and coolers, applied to electric components, cooling/ventilation devices, electrical components, etc., can solve the problems of reduced heat exchange efficiency, complex structure, and large volume, and achieve low cost, small volume, and increased The effect of heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

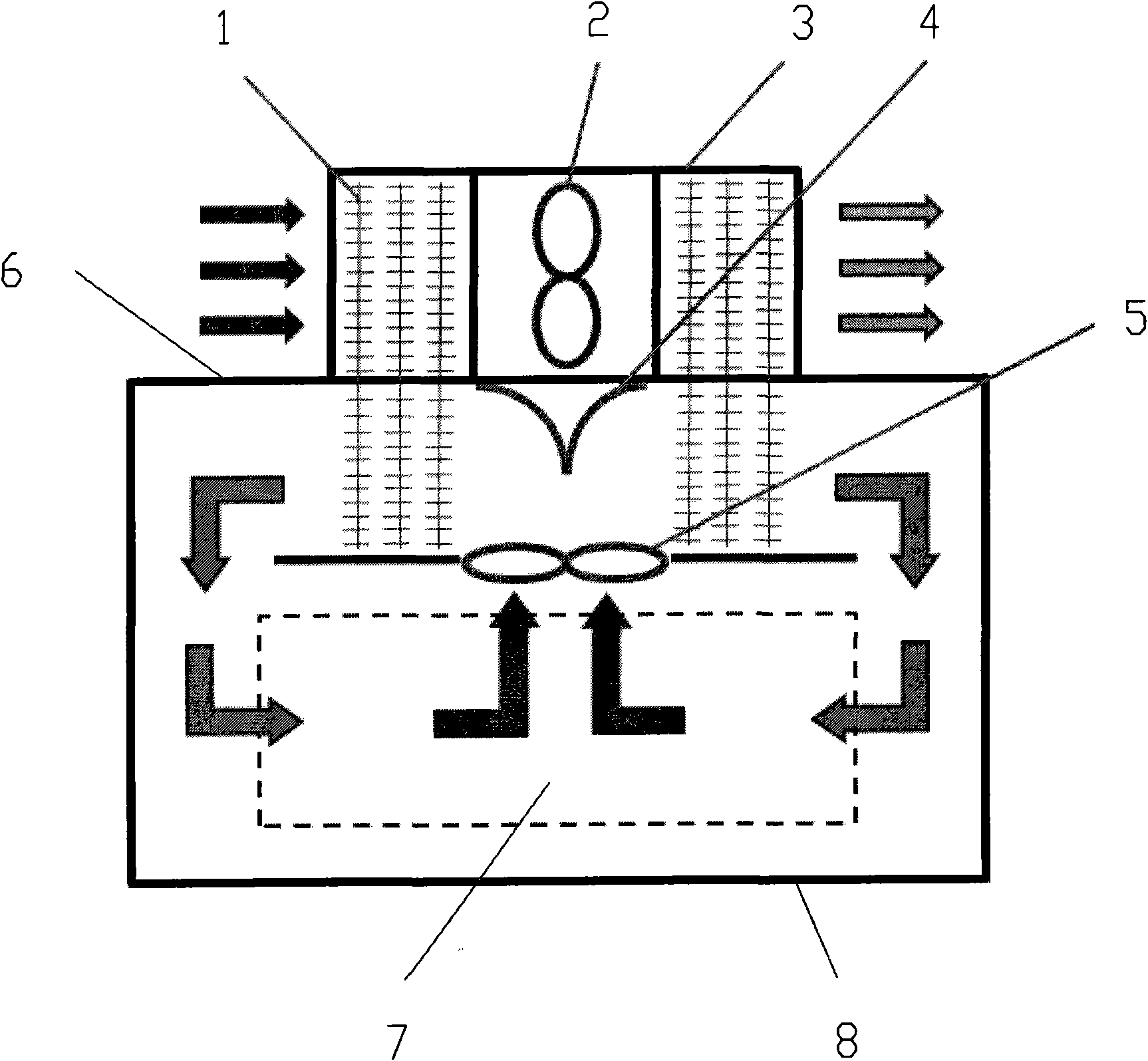

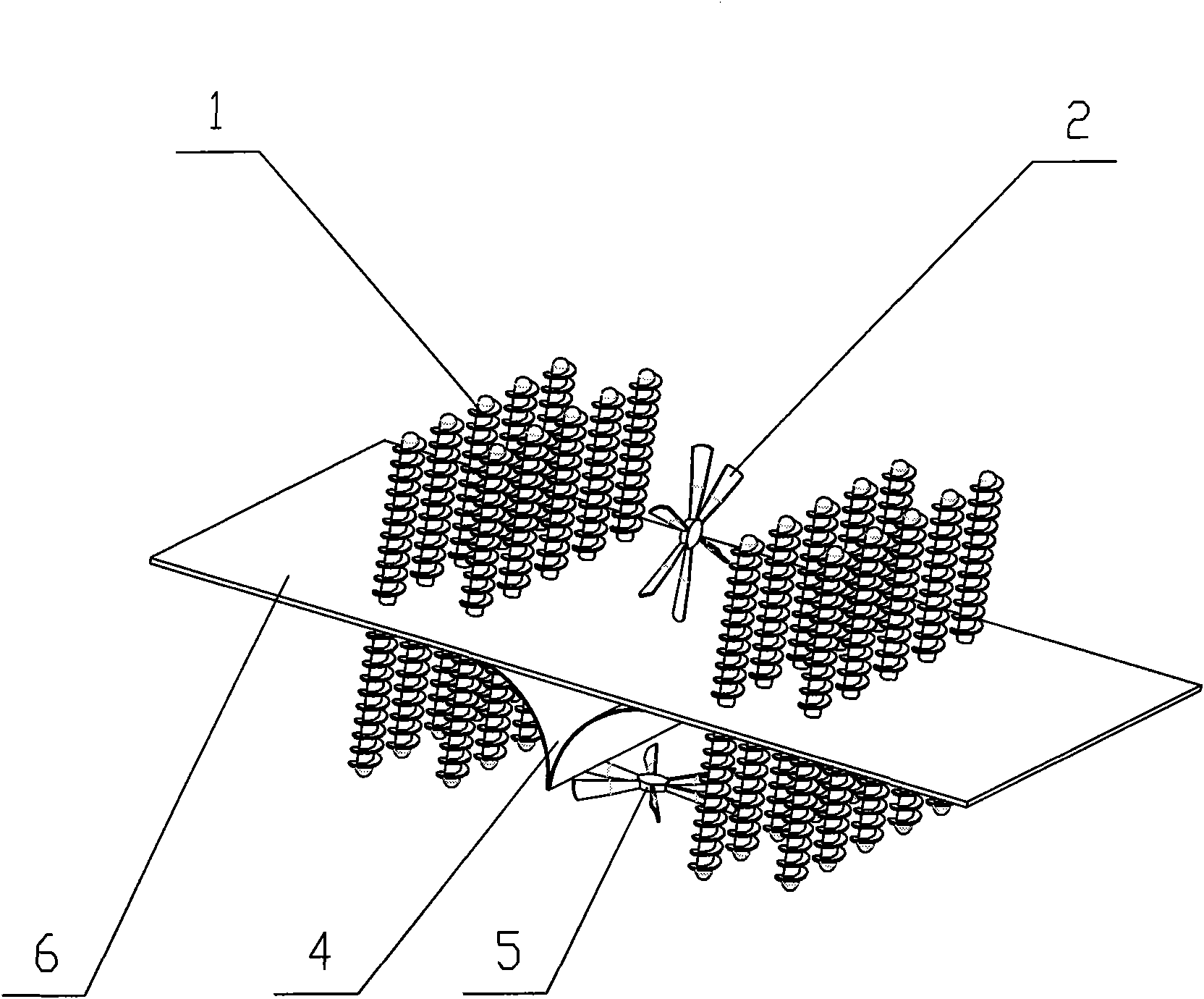

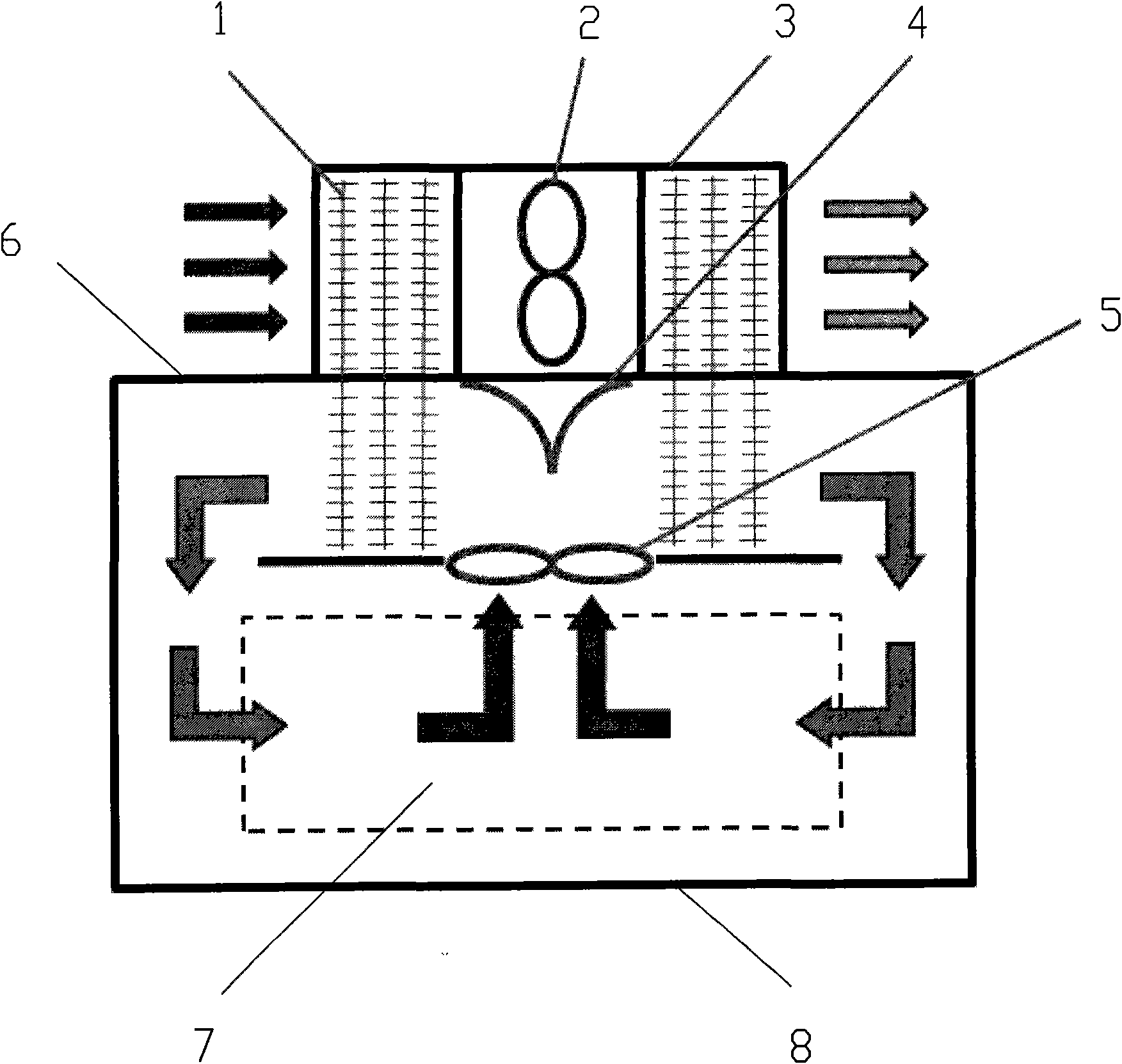

[0020] With reference to the accompanying drawings, the heat pipe type wind turbine cooler of the present invention includes a heat pipe bundle 1, a cold side fan 2, a hot side circulation fan 5 and a cold side air guide cover 3, and the heat pipe bundle 1 is arranged on the generator cabin 7 The top plate 6 is divided into two parts, the top plate 6 is the cold side, and the bottom is the hot side. Since the lower half of the heat pipe bundle 1 is in the generator compartment 7, the generator compartment 7 is well sealed.

[0021] According to the characteristics of the two-way air circulation in the generator cabin 7 , the heat pipe bundle 1 is divided into two parts, and the external cooling fan 2 is located in the middle of the heat pipe bundle 1 . The hot-side circulating fan 5 in the generator cabin 7 is located above the generator, and an air deflector 4 is arranged above the hot-side circulating fan 5, and the air path is divided into two cycles by the air deflector 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com