Dual circulation cooling cooler on hot side of heat pipe wind generating set

A technology for wind turbines and circulating fans, used in wind power generation, cooling/ventilation devices, electric components, etc., can solve the problems of heavy weight, complex structure and large volume, and achieve light weight, compact overall structure and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

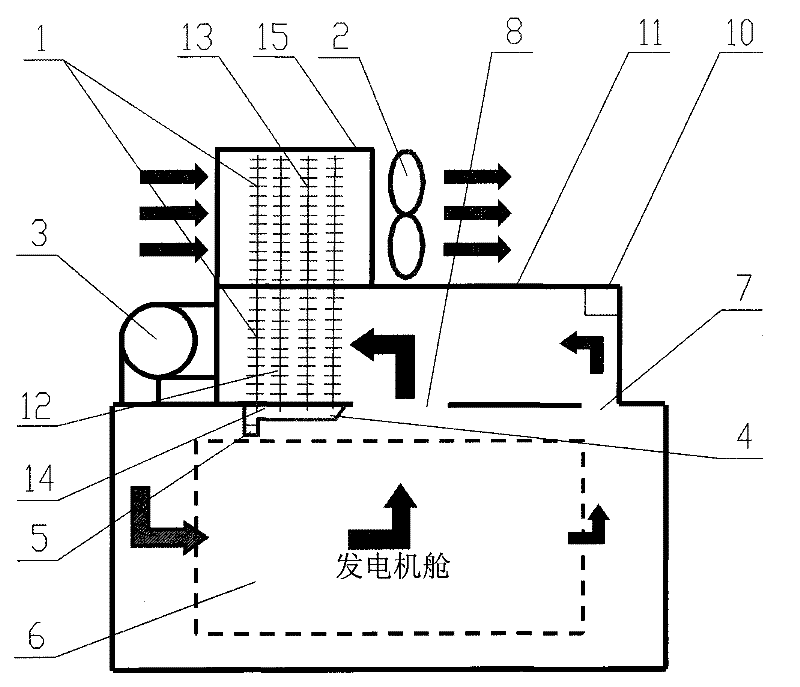

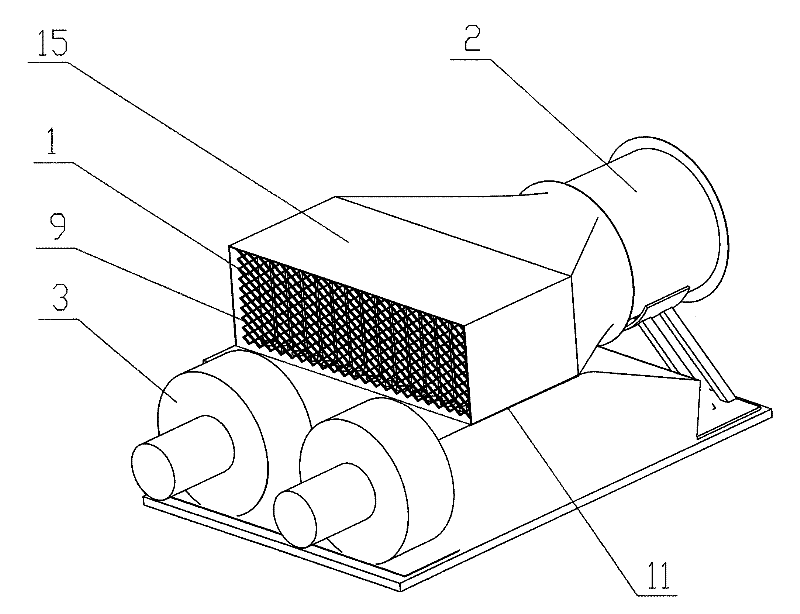

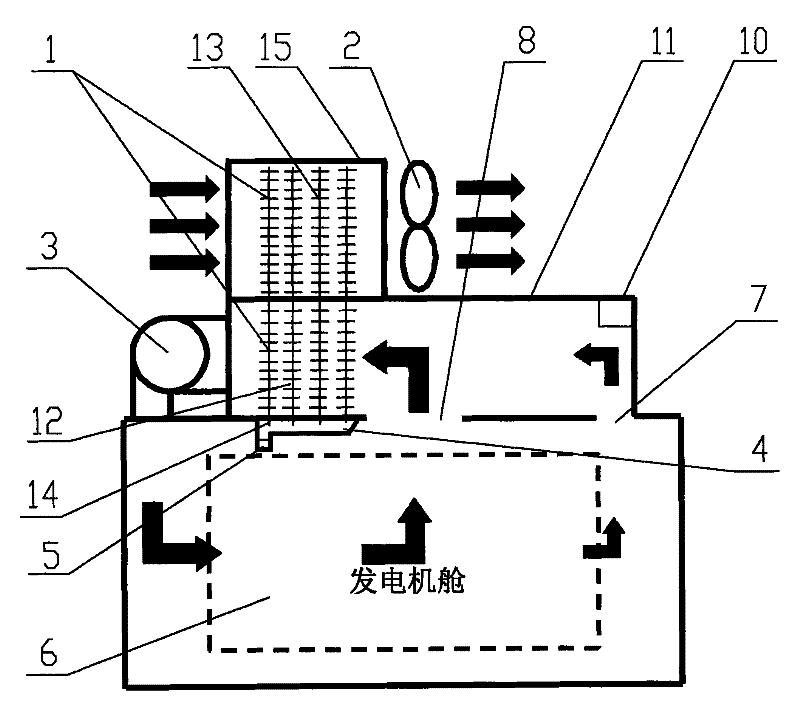

[0021] With reference to the accompanying drawings, the hot-side double-circulation heat pipe type wind turbine cooler of the present invention mainly includes a heat pipe bundle 1, a cold side fan 2, a hot side circulation fan 3 and a cold side wind guide cover 15. The heat pipe bundle 1 It is arranged on the roof 11 of the generator compartment and is divided into upper and lower parts by it. The upper part 13 of the roof is the cold side, and the lower part 12 is the hot side. Since the lower half of the heat pipe bundle 1 is in the generator compartment 6, the generator compartment 6 is well sealed.

[0022] According to the heat dissipation requirements of the generator cabin 6, the air circulation in the cabin is divided into main circulation and auxiliary circulation. Two centrifugal fans 3 are located on the side of the generator cabin close to the heat pipe bundle, and are the main power of the hot side circulation. The main circulation passes through the air above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com