Method for simulating vulcanization process of rubber product

A technology for simulating rubber and rubber products. It is applied in special data processing applications, measuring devices, instruments, etc. It can solve problems such as the inability to give explicit expressions for the degree of vulcanization and accurately describe the kinetic characteristics of rubber vulcanization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A specific embodiment of the present invention will be described below by taking a certain rubber indenter as an example in conjunction with the accompanying drawings. The invention provides a method for simulating the vulcanization process of rubber products for use in figure 1 The computer setup shown performs a computer simulation of rubber vulcanization.

[0014] The computer device 1 includes a host computer 1a, a keyboard 1b and a mouse 1c as input devices, and a display 1d as an output device. The hardware of the host 1a can be configured in general, and the operating system is Windows XP64 or Lunix. Process steps (ie, procedures) for performing the methods described below.

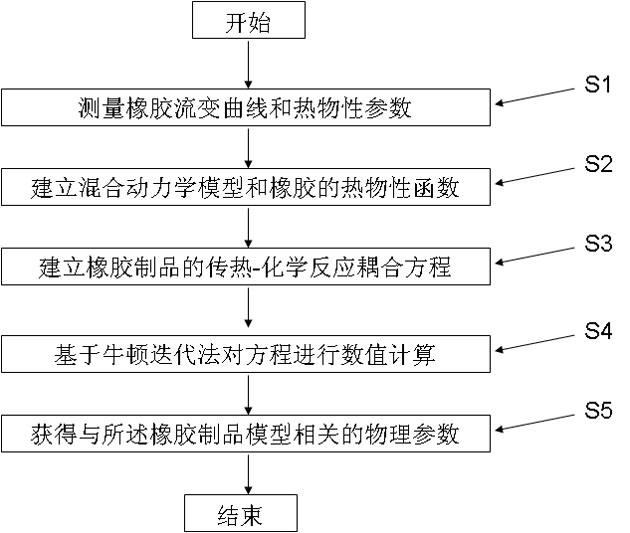

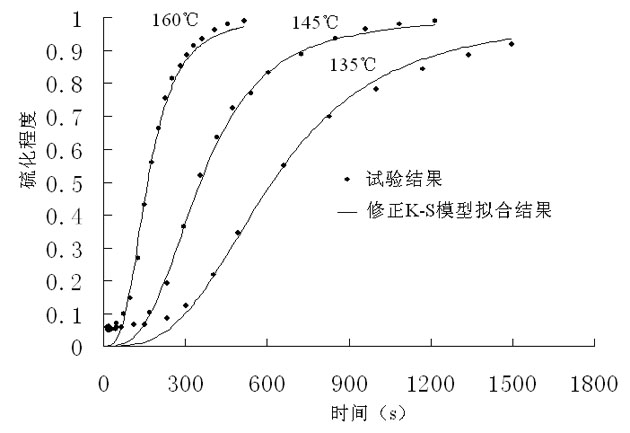

[0015] figure 2 A flow chart showing an example of processing steps (rubber ram vulcanization) for the inventive simulation method. In the embodiment of the present invention, the first step S1 is to measure the rheological curve and thermophysical parameters of the rubber to provide ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com