Chassis leveling system and method

A chassis and leveling technology, applied in the direction of vehicle maintenance, vehicle reloading, use feedback control, etc., can solve the problems of high precision and high speed, and achieve the effect of low precision and slow solution speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

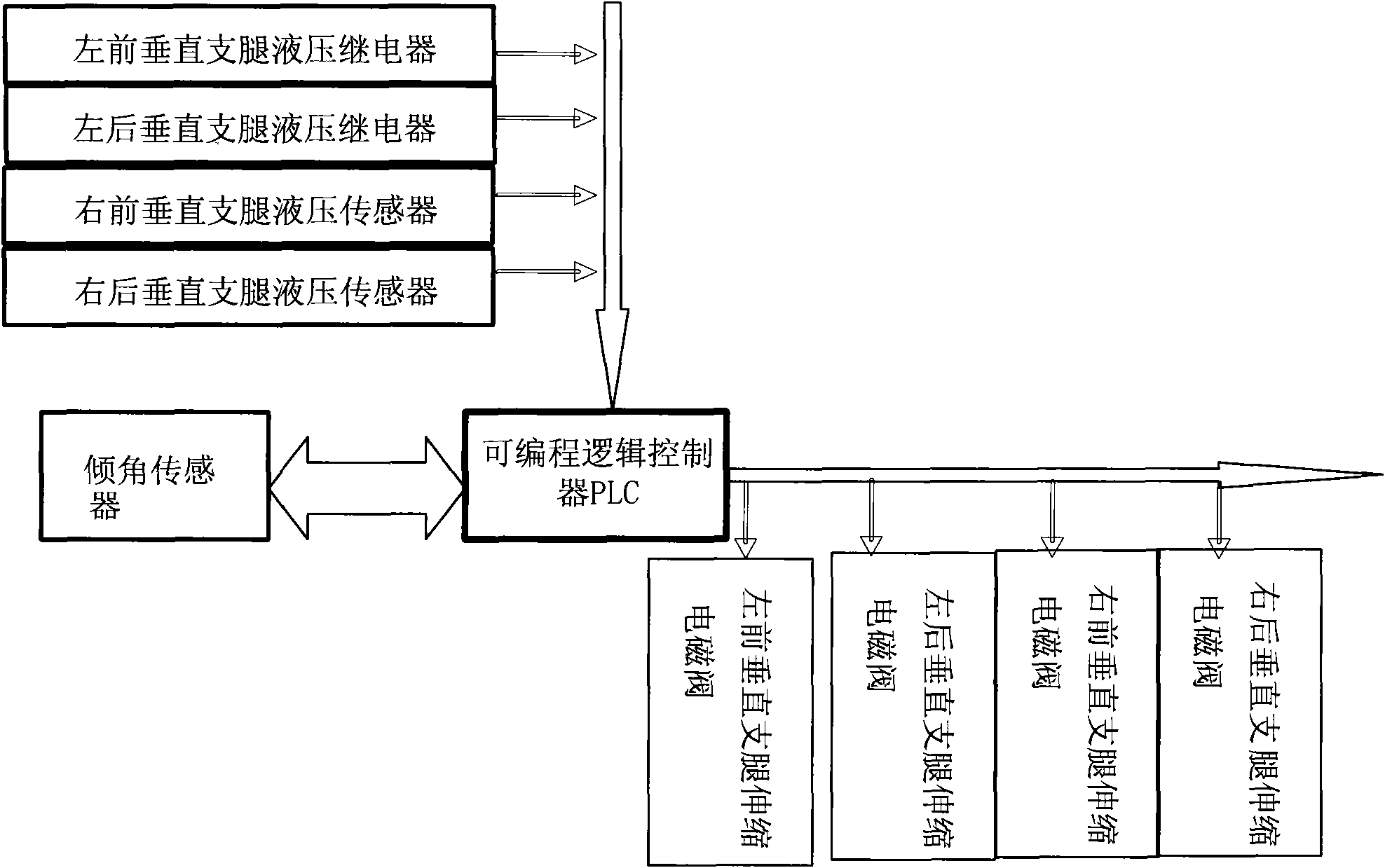

[0040] The structural diagram of the electronic control part of the chassis leveling system disclosed in Embodiment 1 of the present invention is as follows: figure 1 as shown,

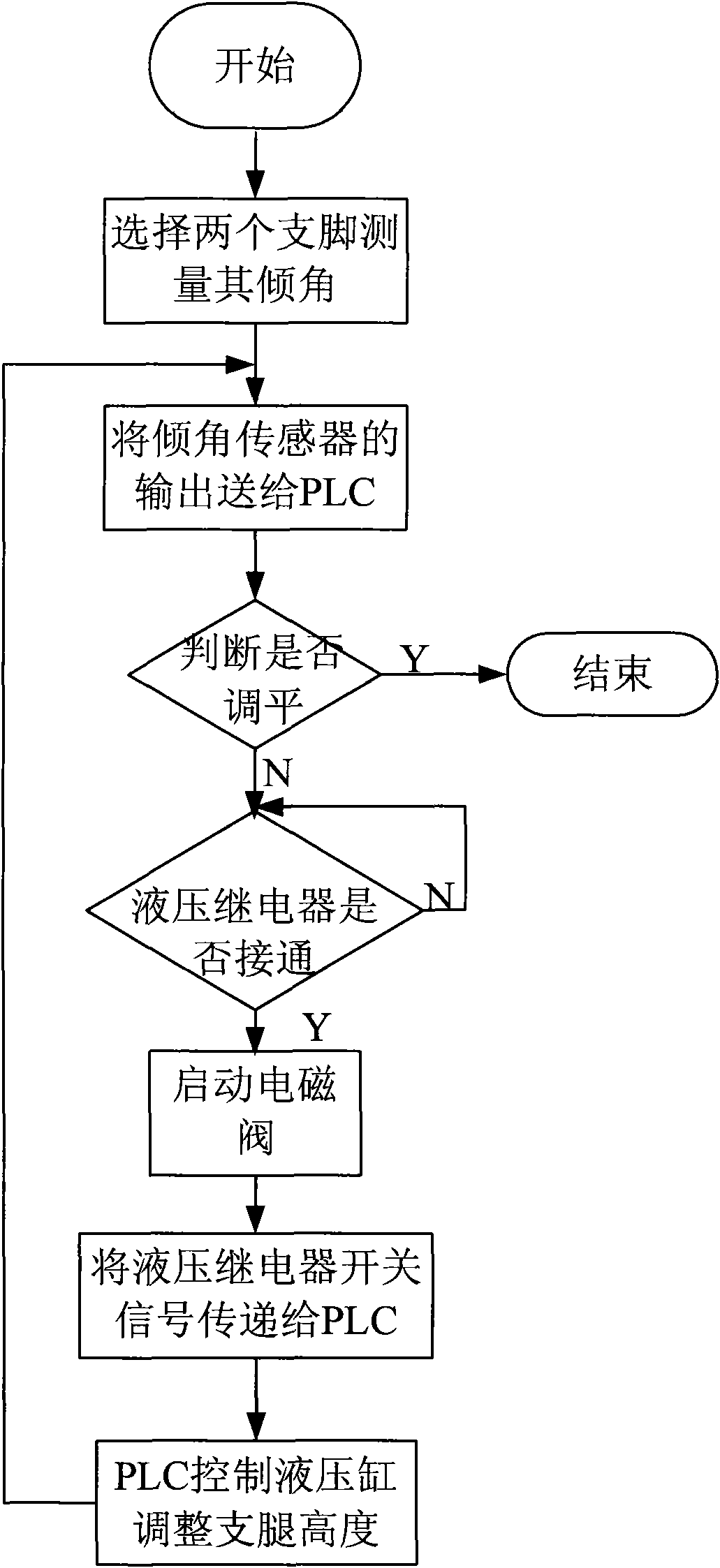

[0041] The hydraulic relays installed on the left front, left rear, right front and right rear legs are used to judge whether the legs are on the ground. The inclination value of leveling two outriggers is passed to the PLC, and the PLC judges whether the value at this time is within the preset range. If it is within the allowable range, it will not level the current outrigger and continue to select other outriggers. If If it exceeds the allowable range, the PLC controls the opening of the hydraulic part to correspond to the vertical outrigger telescopic solenoid valve on the outrigger, and the solenoid valve opens to control the corresponding vertical outrigger telescopic oil cylinder to adjust the height of the outrigger. The height of the outrigger changes, and the inclination angle The output of ...

Embodiment 2

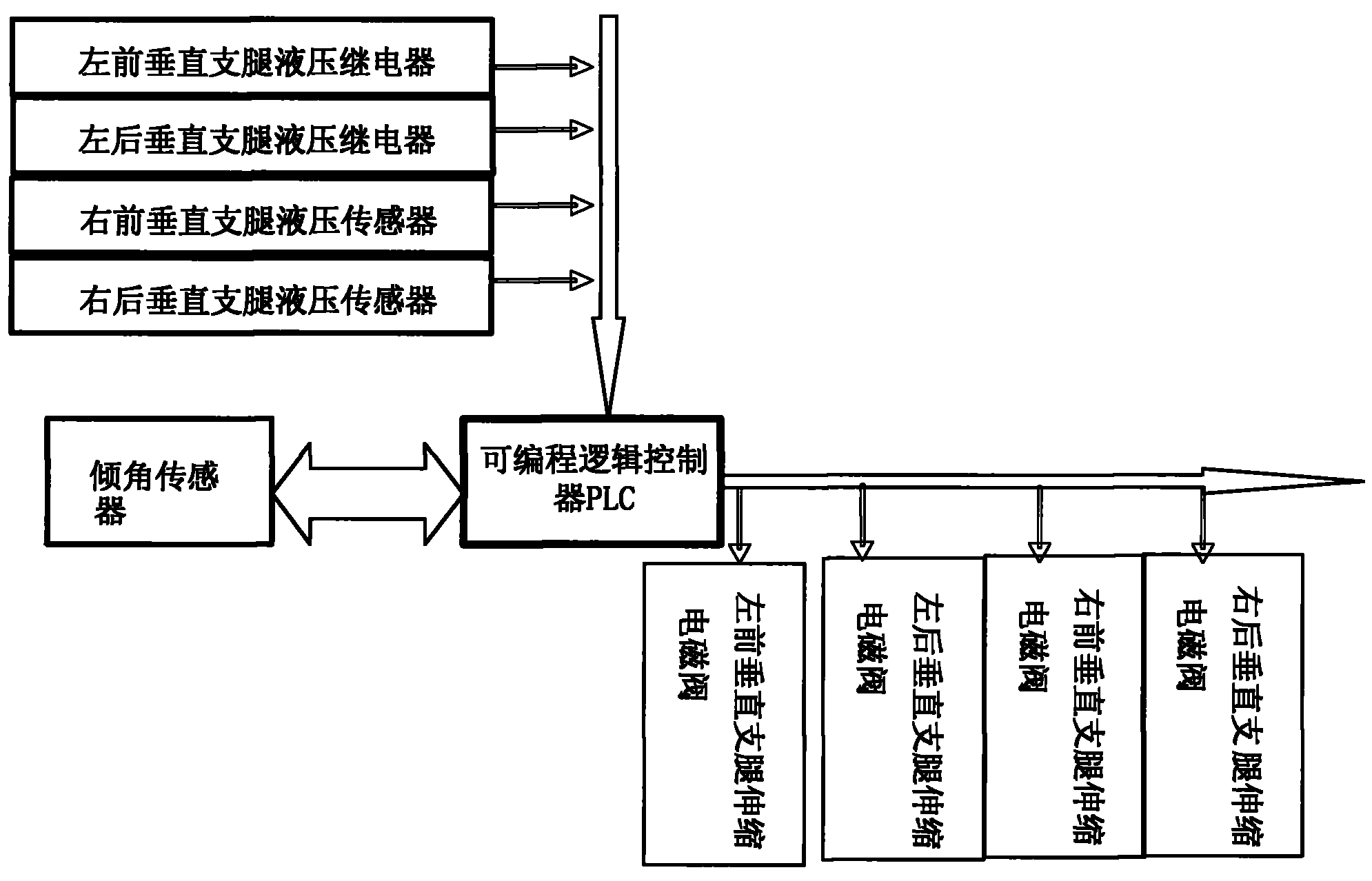

[0051] Embodiment 2 of the present invention is the same as the embodiment in other parts, except that a hydraulic lock is added on each leg. After each leg is leveled during the leveling process, the hydraulic lock on the leg is activated to keep The position of the hydraulic cylinder remains unchanged, ensuring that the leveling result is not affected by the outside world.

[0052] The embodiment of the present invention does not limit the use of the inclination sensor as the leveling sensor, as long as it is a sensor that can measure the height difference between the legs, it can be applied in the present invention, and the embodiment of the present invention does not limit the leveling process to be implemented according to Select the adjusted outrigger as described in Example 1, as long as the height of the four outriggers can be consistent and the chassis can be kept in balance.

[0053] Embodiments of the present invention have at least the following advantages:

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com