Device for measuring ultralow gas flow

A gas flow, extremely small technology, used in the application of thermal effects to detect the direction of fluid flow, etc., to avoid measurement uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

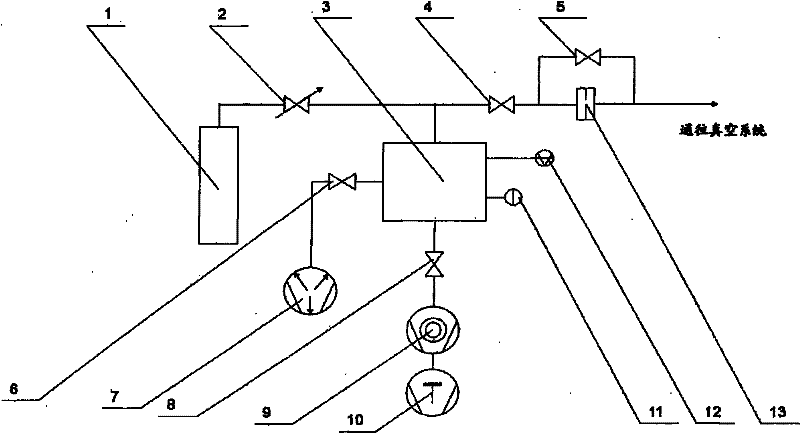

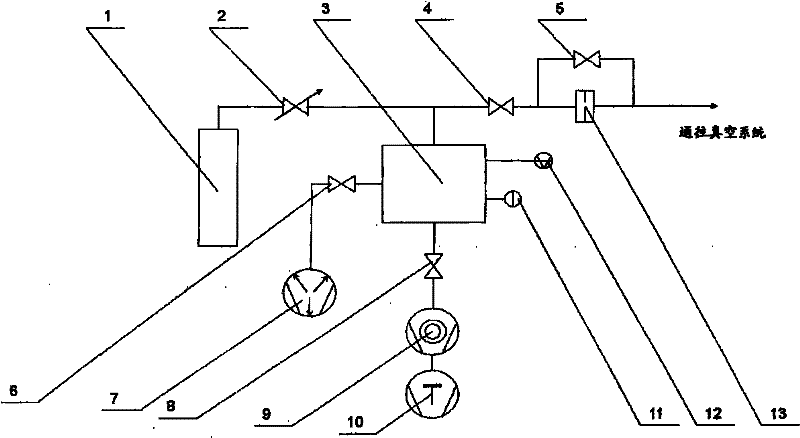

[0022] figure 1 Shown is a preferred embodiment of the present invention, including gas cylinder 1, fine-tuning valve 2, plenum chamber 3, valve 4, valve 5, valve 6, getter pump 7, valve 8, molecular pump 9, backing pump 10. Capacitance film gauge 11, magnetic levitation rotor gauge 12 and small hole 13. The gas cylinder 1 is connected to the plenum 3 through the fine-tuning valve 2. The small hole 13 is connected to the valve 5 in parallel, and one end is connected to the plenum 3 through the valve 4. The other end of the small hole 13 is connected to the vacuum system, the getter pump 7 is connected to the plenum chamber 3 through the valve 6, the backing pump 10 and the molecular pump 9 are connected in series to the plenum chamber 3 through the valve 8, and the capacitive film gauge 11 and the magnetic levitation rotor gauge 12 are directly connected on the wall of the plenum 3 .

[0023] Among them, the getter pump 7 is a non-evaporable getter pump, the molecular pump 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com