Total heat recovery humidifying fresh-air heat pump

A technology of total heat recovery and heat recovery, applied in heat recovery systems, space heating and ventilation, heating methods, etc., can solve the problems of high operating costs, increased cooling load, and small dehumidification, saving operating costs, reducing Dehumidification load, the effect of suitable outlet air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

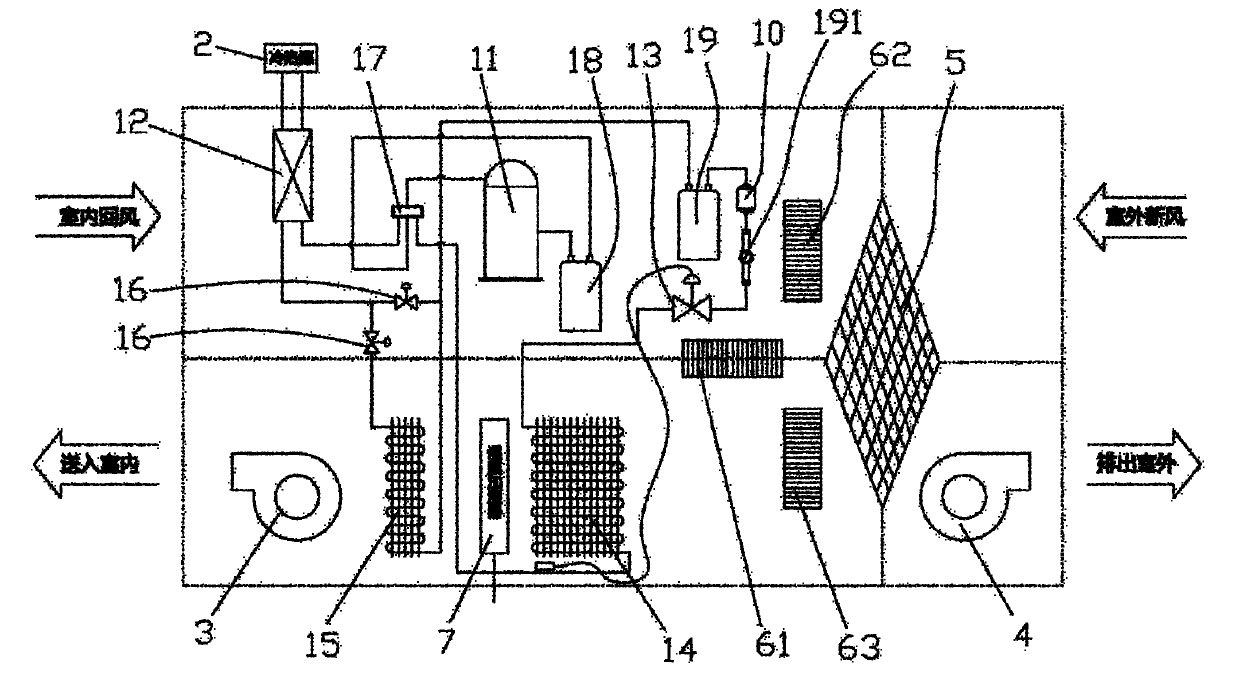

[0025] refer to Figure 1-4 : Humidity-adjusting fresh air heat pump with full heat recovery, including air inlet channel, exhaust air channel, refrigeration system, and central controller. Heater 12, throttling device 13, second heat exchanger 14 for cooling, dehumidifying or heating the fresh air, the second heat exchanger 14 is located in the air inlet channel, and the air blower 3 is arranged in the air inlet channel, An exhaust fan 4 is arranged in the air exhaust passage, and a heat recovery heat exchanger 5 for exchanging heat between fresh air and indoor return air is arranged between the inlet of the air inlet passage and the outlet of the exhaust air passage; the first heat exchange Between the device 12 and the throttling device 13, there is optionally connected a reheater 15 that can reheat the fresh air after cooling and dehumidification. The reheater 15 is located in the second heat exchanger in the air inlet channel along the flow direction of the fresh air. 14...

Embodiment 2

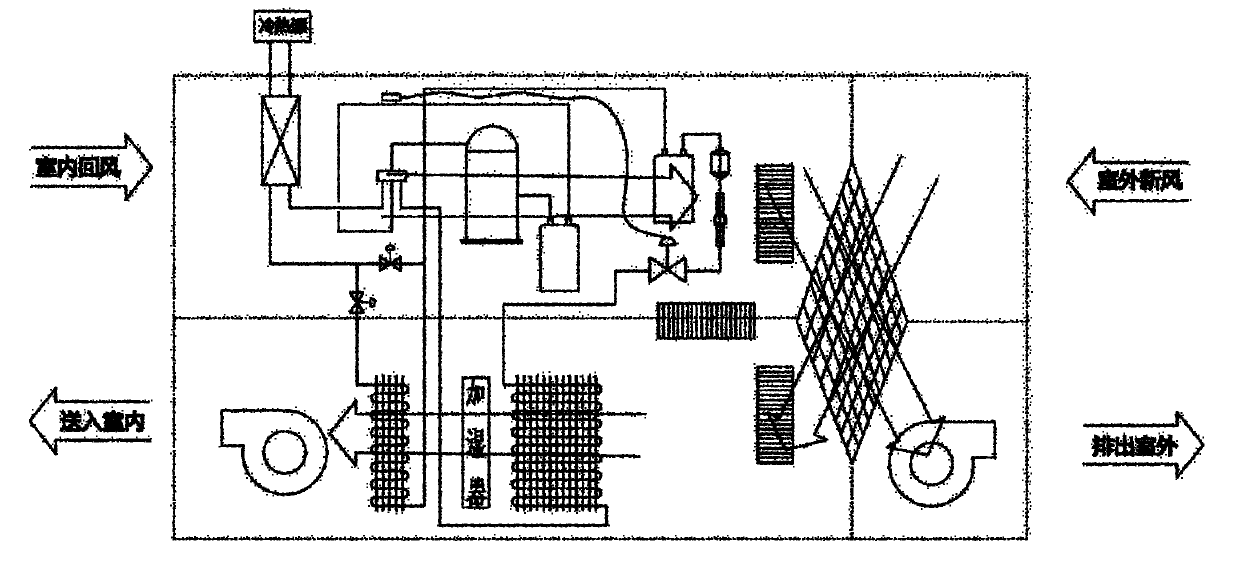

[0045] In this embodiment, the cold and heat source 2 is an air source heat pump, and air is used as the heat exchange source of the first heat exchanger 12 . Other structures and implementations of this embodiment are completely the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com