Pressure-regulating dual anti-burst tire safety valve

A technology for run-flat tires and safety valves, applied in safety valves, valve details, control valves, etc., can solve problems such as inability to automatically adjust tire pressure, valve burst, traffic accidents, etc., and achieve the effect of saving fuel and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

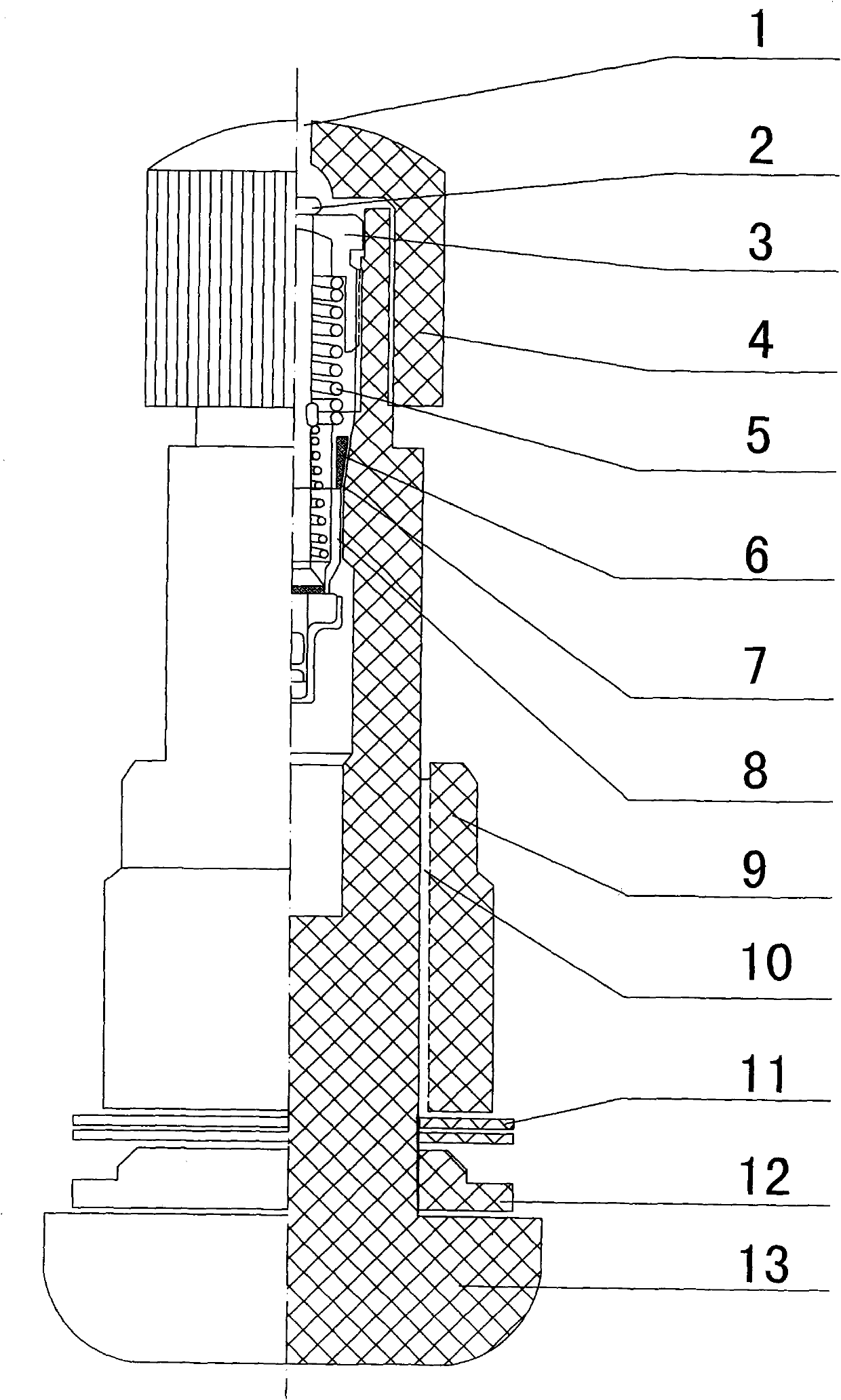

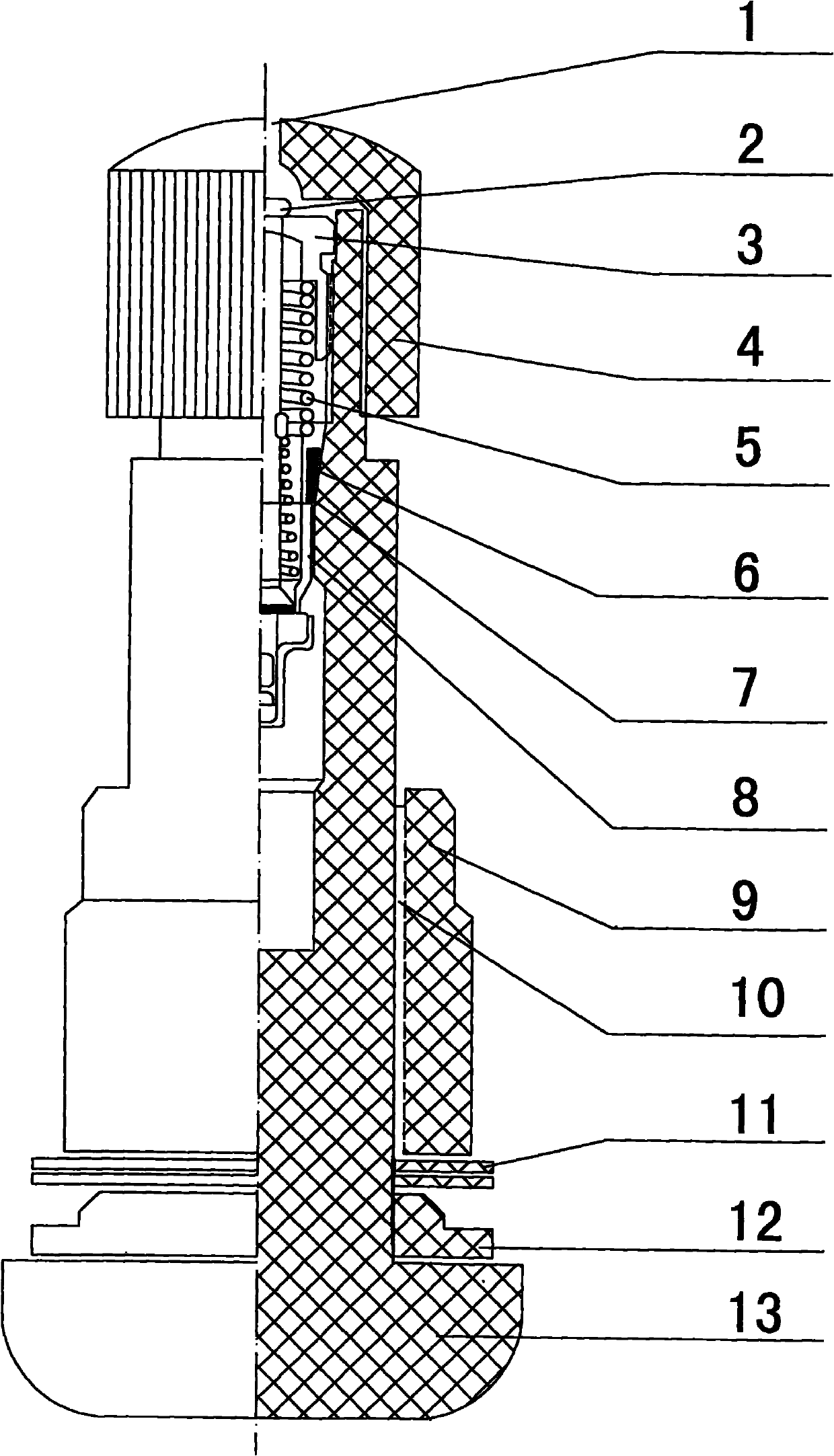

[0011] As shown in the figure, 1 is a vent hole, 2 is a core rod, 3 is a core cap, 4 is a dust cap, 5 is a pressure limiting spring, 6 is a sealing ring, 7 is a ventilation channel, 8 is a core body, and 9 is a pressure cap. Tight nut, 10 is thread, and 11 is sealing rubber gasket A, and 12 is sealing rubber gasket B, and 13 is valve body.

[0012] The core rod 2 is lengthened on the existing basis, and the pressure limiting spring 5 is installed between the core body 8 and the core cap 3. There is a prominent positioning point at the top of the core cap 3, which is the outer edge of the cap, and the outer edge of the cap outer edge of the positioning point If the diameter is greater than that of the thread of the core cap, it is greater than the inner diameter of the core cap, and the distance between the positioning point of the core cap 3 and the sealing point on the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com