Method for producing turbid beer or turbid white beer

A production method and technology of cloudy beer, which is applied in the field of production of cloudy beer or cloudy white beer, to achieve the effect of soft and mellow taste and strong killing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

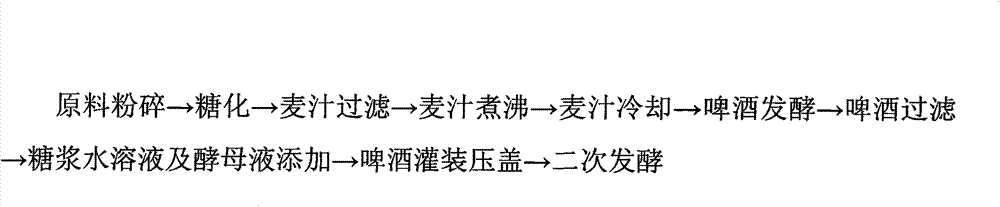

[0018] like figure 2 Shown, the cloudy beer production method described in the present embodiment is the improvement done on the basis of existing cloudy beer technology, specifically as follows:

[0019] 1. Between the beer fermentation process and the beer filling and capping process, the beer filtration process, the syrup aqueous solution and the yeast liquid addition process are sequentially added. After the beer fermentation process is completed, it is necessary to filter (or centrifuge, clarify) the fermented wine liquid, and add syrup aqueous solution and yeast liquid to the filtered wine liquid, wherein: the concentration of the syrup aqueous solution is 30-65%, adding The amount is 7.7-26.7g / L filtered liquor; the yeast suspension concentration in the yeast liquor is 20-70×10 6 per ml, and added to the filtered wine at a volume ratio of 1:10 to 1:233.

[0020] After the beer filling and capping process, the fermentable sugar concentration of the wine liquid is 5-8g...

Embodiment 2

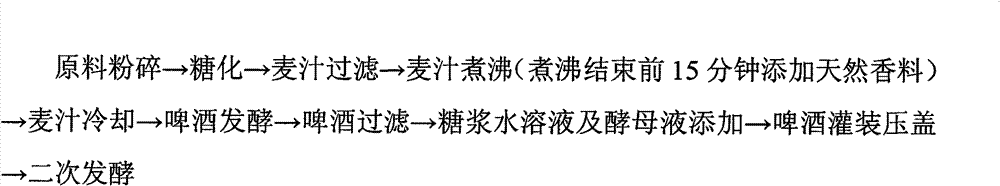

[0023] This embodiment improves the wort boiling process on the basis of embodiment 1. That is, in the wort boiling process, 15 minutes before the completion of wort boiling, natural flavors are added to the wort, so that the aroma substances of the natural flavors are released into the wort.

[0024] The natural spice is preferably selected from any one or a combination of coriander seeds, fresh / dried orange peel, fresh / dried orange peel, fresh / dried lemon peel and fresh / dried grapefruit peel. If coriander seeds are added separately, the addition amount is 800g-1200g / kl of wort. Another example is that coriander seeds can be used as the main spice, and the addition amount is 800g-1200g / kl wort; the combination of fresh / dried orange peel and fresh / dry orange peel can be used as auxiliary spices, and the addition amount is 200g-400g / kl wort . Another example is to add fresh / dried lemon peel separately, and the addition amount is 200g-600g / kl of wort. Another example is to ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com