Method and device for producing super active carbon

A production device and production method technology, applied in the field of super activated carbon production methods and production devices, can solve the problems of affecting KOH purity, affecting super activated carbon production process stability, super activated carbon quality, unfavorable KOH reuse, etc., to eliminate potential safety hazards. , The pore structure is developed, and the effect of increasing the activation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

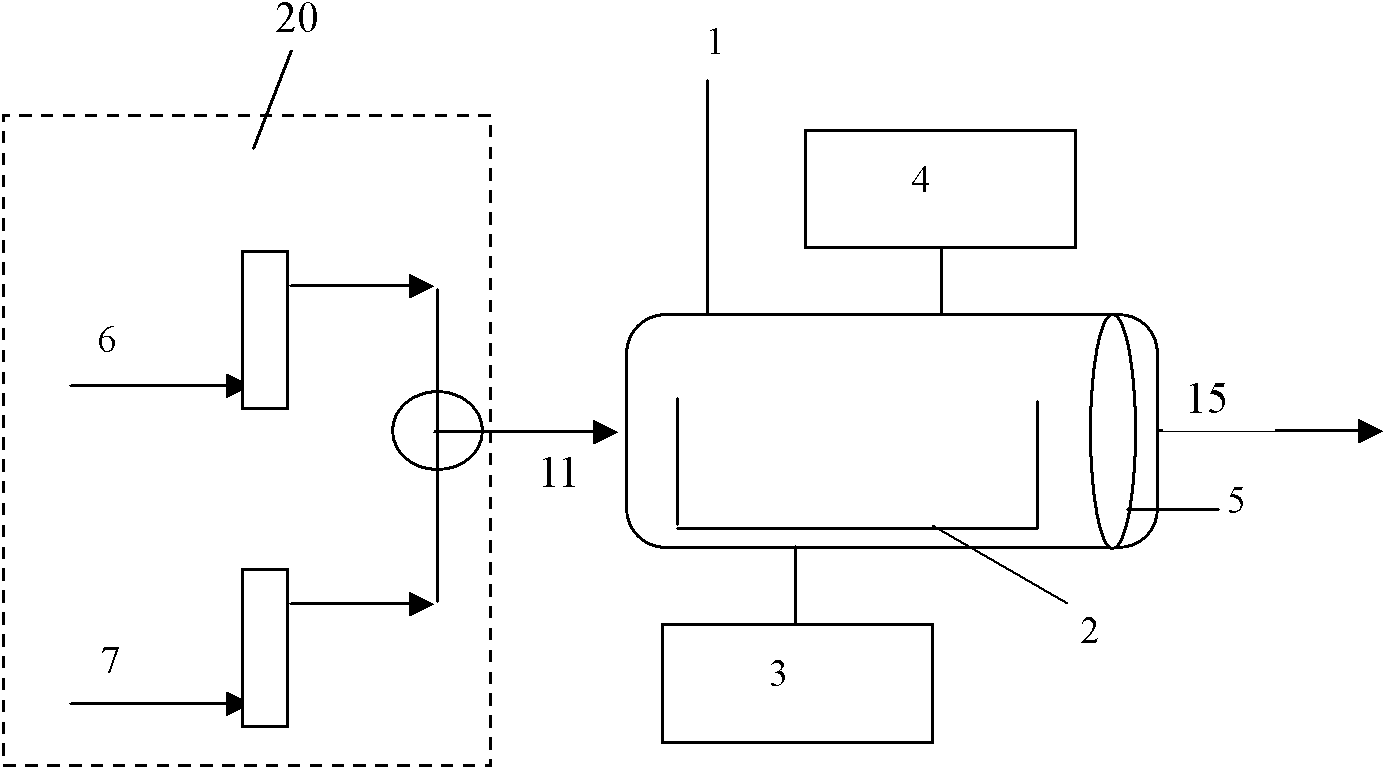

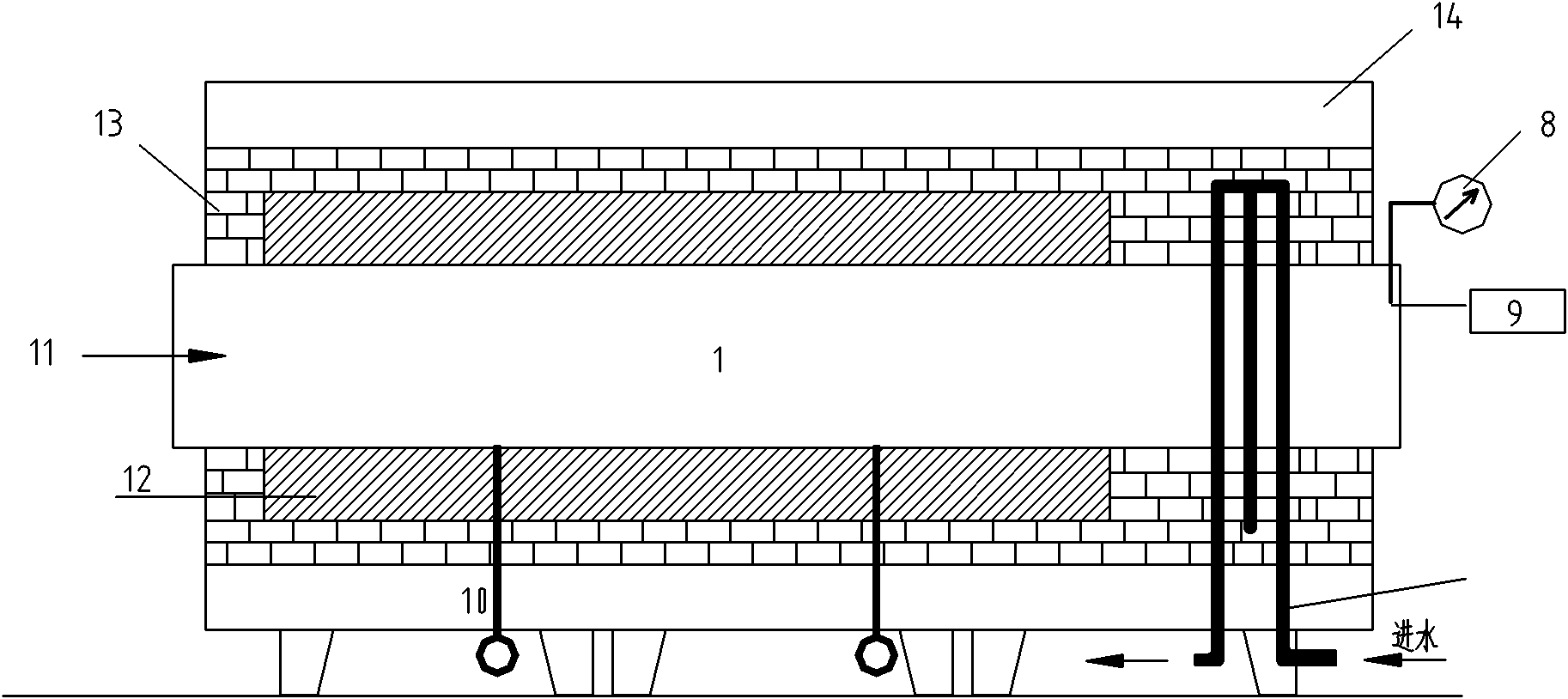

[0042] Such as figure 1 with figure 2 Shown, a kind of production device of super active carbon of the present invention, it comprises activation furnace body 1, reaction vessel 2, pressure control system 4, temperature control system 3, air intake system 20 and condensation pipe 5.

[0043] The reaction vessel 2 is placed in the activation furnace body 1 . The reaction vessel 2 is made of nickel material.

[0044] The activation furnace body 1 is connected to the pressure control system 4 , the temperature control system 3 and the air intake system 20 respectively. The intake system 20 includes an inert gas supply system 6 and an air supply system 7, which can realize the intake switch between inert gas and air.

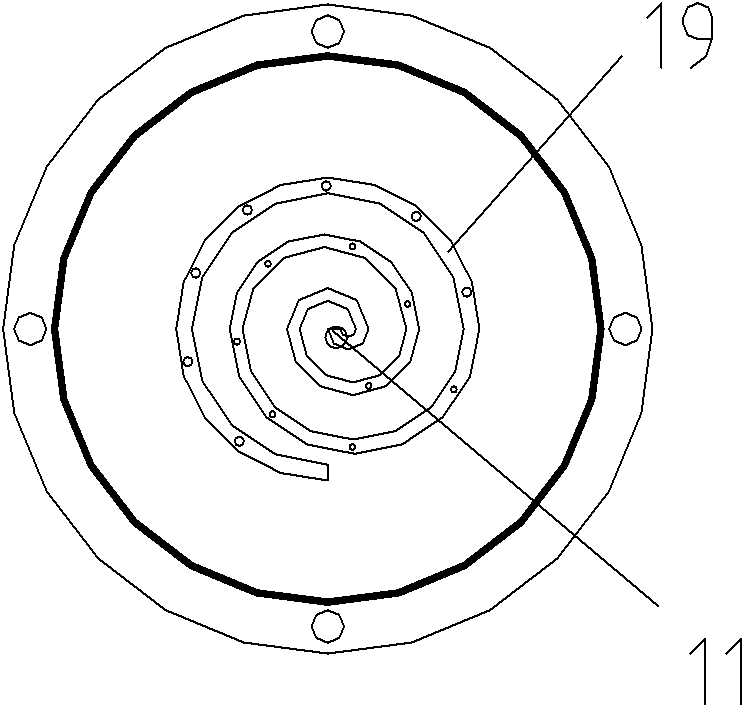

[0045] The activation furnace body 1 is provided with a furnace front cover at the air inlet 11, and a furnace rear cover at the gas outlet 15 place. The activation furnace body 1, the furnace front cover and the furnace rear cover are made of alkali-resistant ...

Embodiment 2

[0050] Petroleum coke and KOH were mixed in a weight ratio of 1:4, and then put into a reaction vessel 2 made of nickel. Then open the circulating condensed water in the cooling part 16 of the sealing ring and the circulating condensed water in the condenser pipe 5, and feed nitrogen gas to raise the temperature to 400° C. at a heating rate of 5 K / min, and keep the temperature constant for 2 hours. Start to adjust the pressure control valve 9 to make the pressure in the tank reach 3 atmospheres, then rise to 750°C at a heating rate of 3K / min, and activate for 2 hours. Then cool down to below 150°C under the condition of feeding nitrogen, then switch nitrogen to air, and continuously pass air into the furnace body for more than 2 hours. After the temperature in the furnace body drops to above 100°C, open the front cover of the furnace and push out the reaction Container 2, take out the activation material. Wash the activation material with water, and rinse the furnace front co...

Embodiment 3

[0052] Petroleum coke and KOH were mixed in a weight ratio of 1:4, and then put into a reaction vessel 2 made of nickel. Then turn on the circulating condensed water in the cooling part 16 of the sealing ring and the circulating condensed water in the condensation pipe 5, and feed nitrogen gas to raise the temperature to 500° C. at a heating rate of 5 K / min, and keep the temperature constant for 1 hour. Start to adjust the pressure control valve 9 to make the pressure in the tank reach 2 atmospheres, then rise to 700°C at a heating rate of 3K / min, and activate for 3 hours. The technological processes such as subsequent cooling, ventilation and washing recovery of KOH, determination of KOH solution concentration, post-treatment of activated carbon are the same as in Example 2. The results of the KOH recovery rate and the pore structure test of activated carbon are shown in Table 1. With the treatment method and device of the present invention, no elemental potassium is found i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com