Hydrofoil for water-borne vessels

A vehicle and hydrofoil technology, applied in the field of hydrofoils with trailing edges, can solve problems such as reduced rudder force and reduced working efficiency of hydrofoils, so as to increase hydrofoil resistance, improve fuel efficiency, and reduce the risk of damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In the various embodiments of the present invention described below, the same components are provided with the same reference signs.

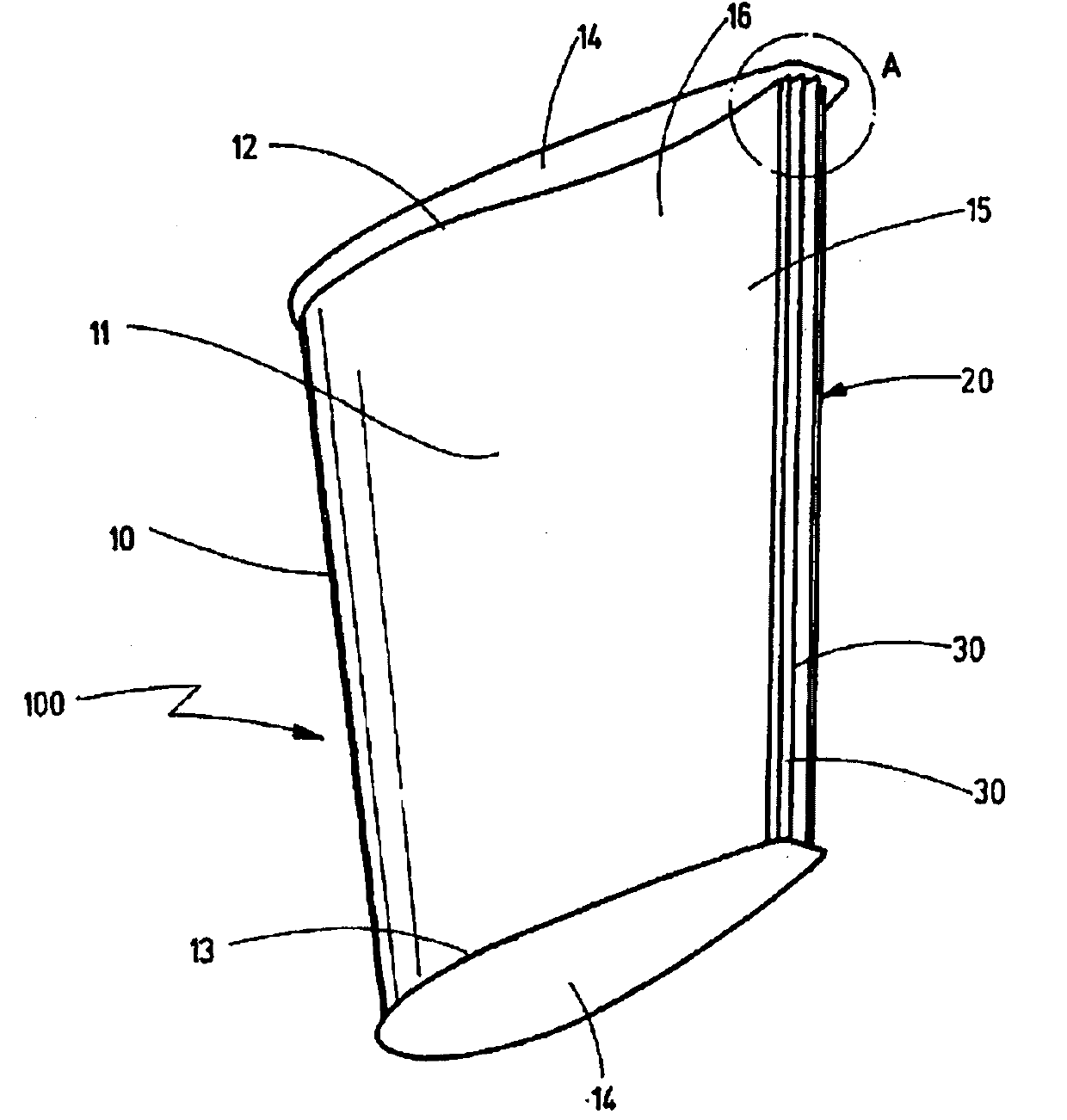

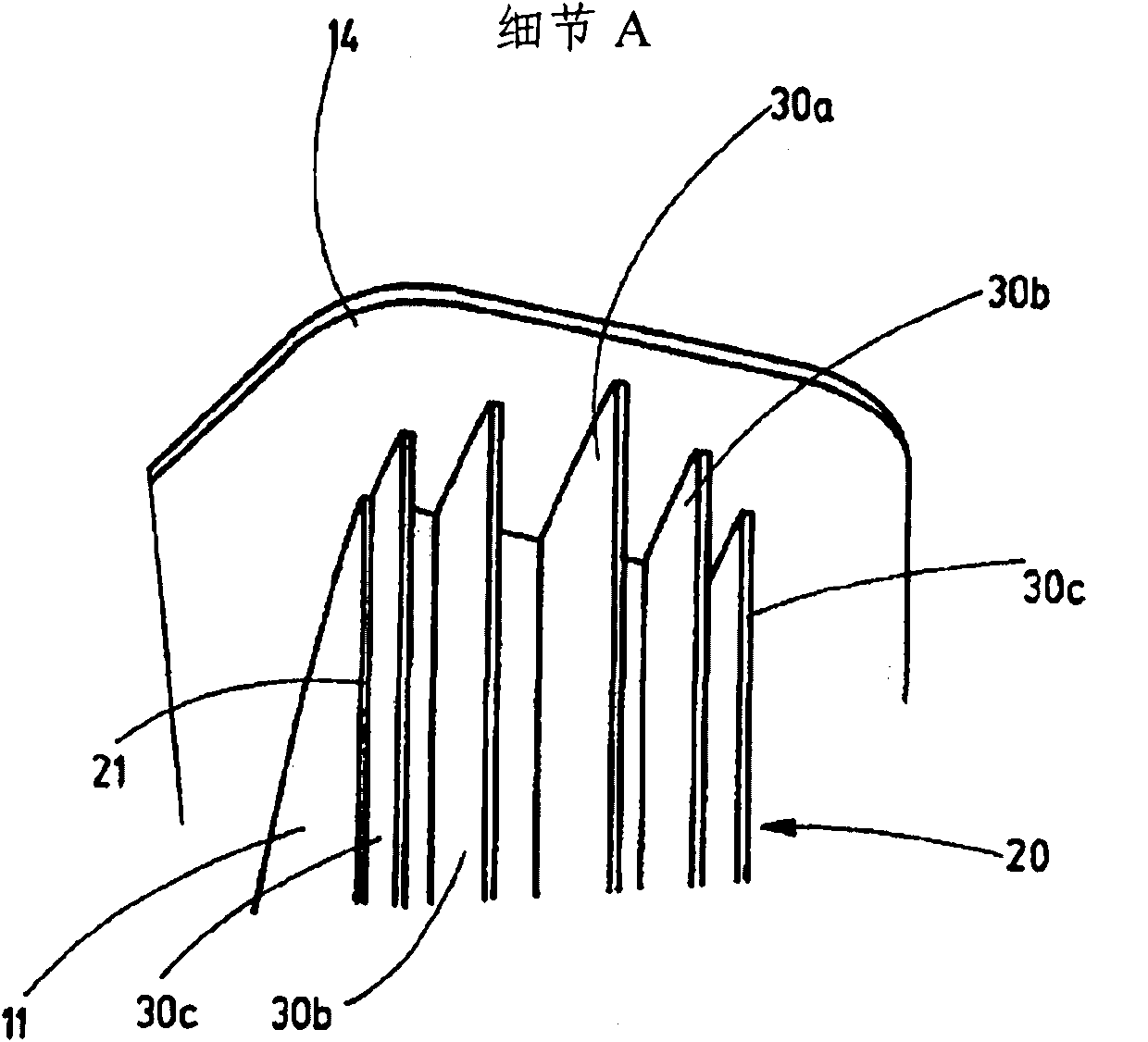

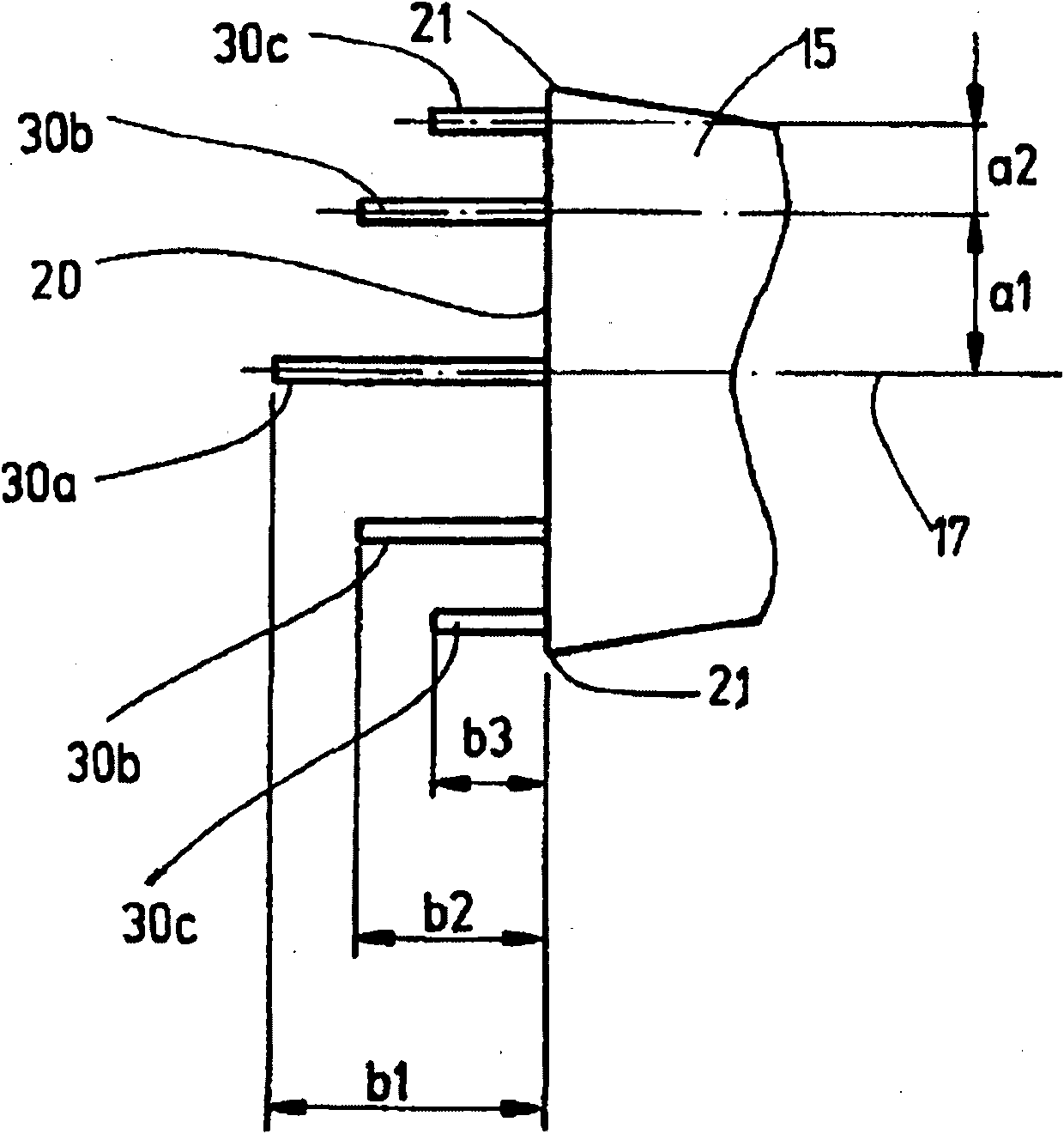

[0052] figure 1 A perspective view of the hydrofoil 100 is shown. In this case, the hydrofoil 100 has a fishtail shape or shilling (Schilling ) The shape of the rudder is formed. The rudder includes a leading edge 10 and a trailing edge 20. The side surface 11 extends between the leading edge 10 and the trailing edge 20. The end plates 14 are provided at the upper end 12 and the lower end 13 of the hydrofoil 100 in each case. Because the hydrofoil 100 adopts the form of a rudder with a fishtail shape, the end 15 of the rudder widens from the rear area 16 forming the narrowest part of the rudder to the trailing edge 20. A total of 5 protrusions 30 designed as plate-shaped ribs are provided at the trailing edge 20, which extend from the upper end 12 to the lower end 13 in each case and are arranged parallel to each other.

[0053] From ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com