Method for designing mobile extraction tube rack

A design method and the technology of the pumping tube are applied to the device and coating of the surface coating liquid, which can solve the problems of waste, heavy pumping tube, and spending a lot of time looking for it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

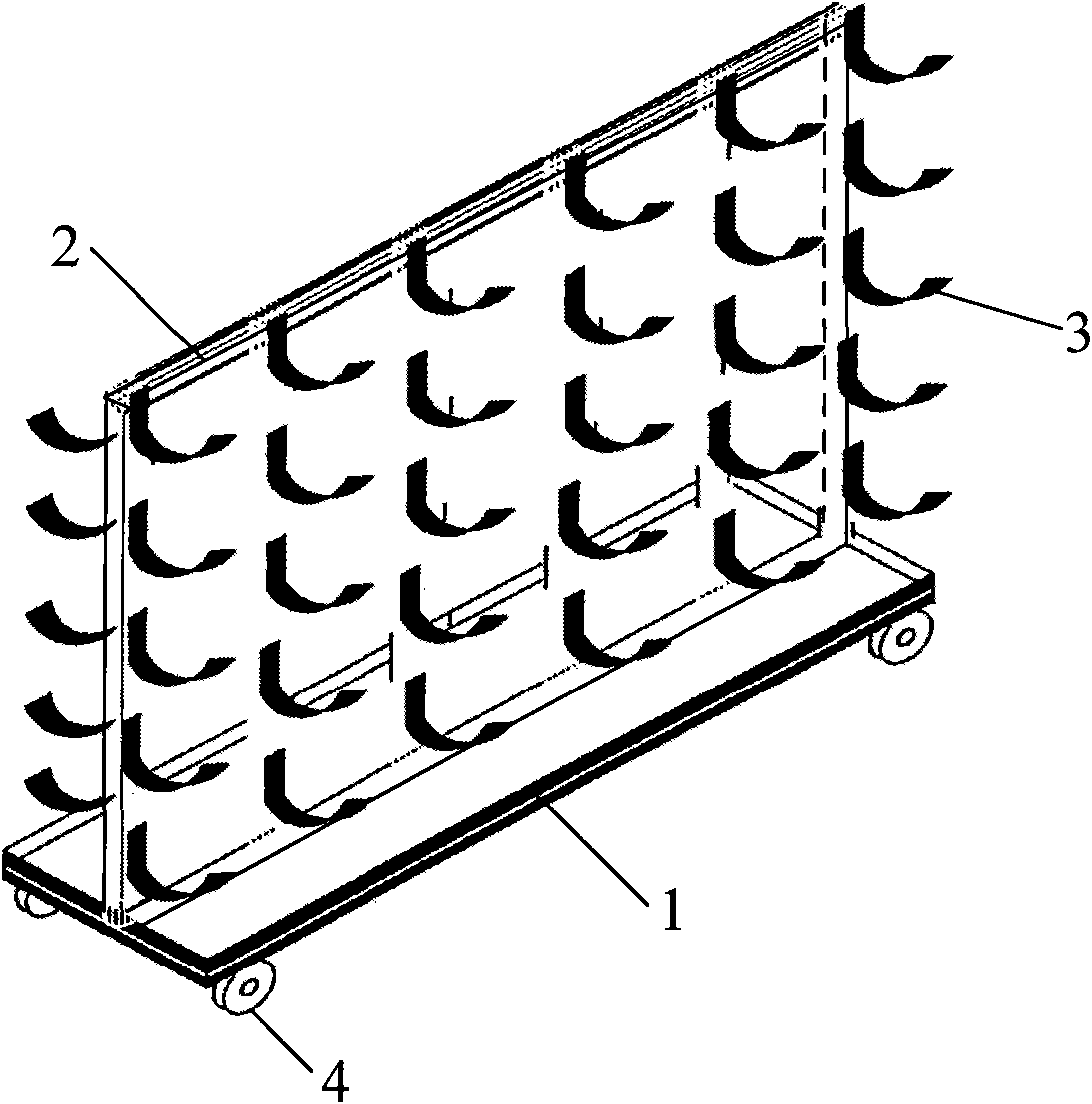

[0014] Such as figure 1 As shown, the movable type pumping tube placement frame includes a tray 1 and universal rollers 4, and the universal rollers 4 are installed on the bottom surface of the tray 1, and each universal roller 4 is provided with brake pads; An upright support plate 2 has a number of curved hooks 3 distributed on both side walls of the support plate 2, and the curved hooks 3 are arranged regularly along the horizontal and vertical directions.

[0015] The tray 1 is used to support the support plate 2, and it is convenient to clean up the dripping paint; the curved hook 3 on the support plate is used to hang the suction pipe; the four rollers 4 under the tray 1 can control the movement and stop of the entire shelf , the entire rack is easy to move when in use, and it is firm and stable when hanging the pumping pipe.

[0016] To sum up, the present invention can satisfy the placement of various pumping pipes of different specifications, occupies a small area, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com