Composite hydrogen storage material for complexing hydrides and hydrogen storage alloys

A technology of hydrogen storage materials and hydrogen storage alloys, which is applied in the production of hydrogen, chemical instruments and methods, and other chemical processes to achieve good reversible hydrogen storage and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] N component: configure TiMn according to stoichiometric ratio 2 The alloy was prepared by induction melting. After mechanical crushing to -40 mesh, under the protection of 2.5-4MPa hydrogen atmosphere, ball to material ratio 20:1-30:1, 400-450rpm rotation speed, ball milling for 40-50 hours to obtain alloy powder with an average particle size of 25μm.

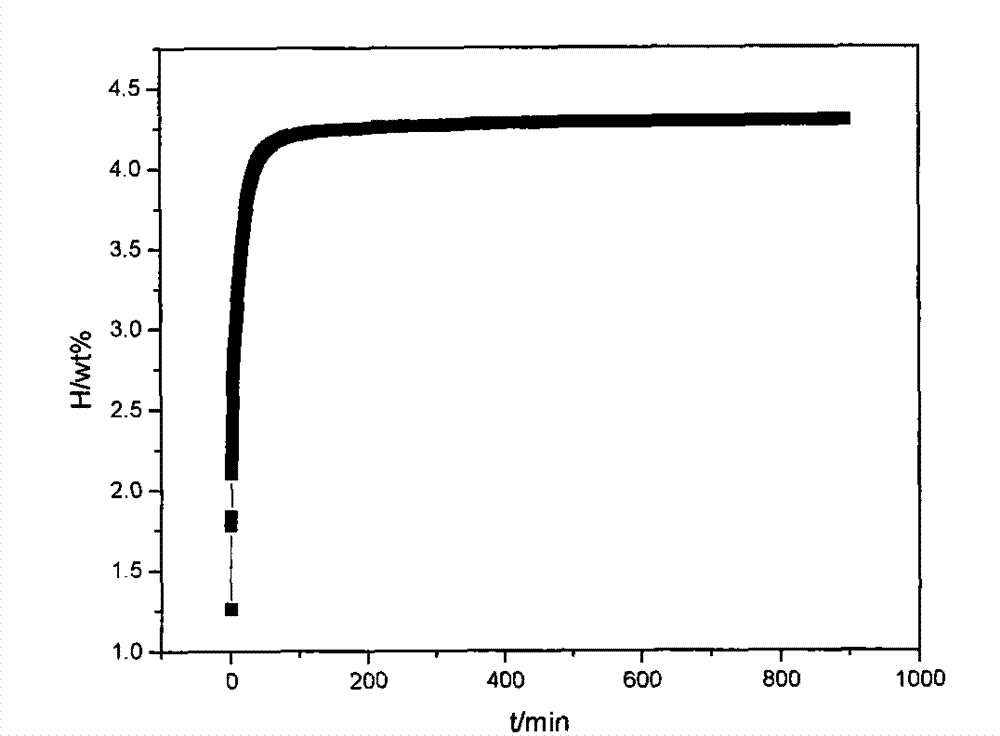

[0023] Composites: To NaAlH 4 10 wt. % of the above alloy powder relative to the total amount of the composite hydrogen storage material is added to the powder, which is sealed with the steel ball in a ball mill, and the ball-to-material ratio is 10:1-20:1. The ball mill tank is evacuated and filled with hydrogen with a purity of > 99.99% at 2-3 MPa, and the ball milling time is 3-5 hours under the condition of a speed of 350-400 rpm to obtain a composite material with an average particle size of figure 2 (the abscissa time / min in the figure represents the hydrogen absorption time, and the ordinate H / wt% represents the...

Embodiment 2

[0025] N component: LaNi is configured according to the stoichiometric ratio 5 The alloy was prepared by induction melting. After mechanical crushing to -40 mesh, ball mill is used for 30-35h under the protection of 2-3MPa hydrogen atmosphere.

[0026] Composites: To NaAlH 4 5 wt. % of the above alloy powder relative to the total amount of the composite hydrogen storage material is added to the powder, which is sealed with the steel ball in a ball-milling tank, and the ball-to-material ratio is 15:1-20:1. The ball mill tank is evacuated and filled with hydrogen with a purity of >99.99% at 2-3.5MPa, and the ball milling time is 2-5 hours to obtain a composite material with an average particle size of image 3 (the abscissa time / min in the figure represents the hydrogen absorption time, and the ordinate H / wt% represents the gravimetric hydrogen absorption capacity). The reversible hydrogen release of the composite material was 4.2 wt. %, and the hydrogen release process was co...

Embodiment 3

[0028] N component: prepare the alloy according to the stoichiometric ratio of titanium 26at.%, chromium 20at.%, vanadium 45at.%, iron 8.5at.%, and prepare Ti by induction melting 26 Cr 20 V 45 Fe 9.0 The alloy is mechanically crushed to -40 mesh, and then ball milled for 30-35h under the protection of 3-5MPa hydrogen atmosphere, the ratio of ball to material is 20:1-25:1, and the speed is 400-450rpm to obtain powder with an average particle size of 15μm.

[0029] Composite material: add 40wt.% of the above alloy powder relative to the total amount of the composite hydrogen storage material to the powder mixture of NaH:Al=1:1, and seal it with the steel ball in a ball mill, with a ball-to-material ratio of 25:1-30:1 . The ball mill tank is evacuated and filled with hydrogen with a purity of 6-8MPa> 99.99%, and the ball milling time is 8-10 hours to obtain a composite material with an average particle size of Figure 4 (the abscissa time / min in the figure represents the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com