Pressure sensor for electric pressure cooker

A pressure sensor, electric pressure cooker technology, applied in pressure cookers and other directions, can solve the problem of not being able to transmit pressure signals to the control device, and achieve the effect of eliminating potential safety hazards and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

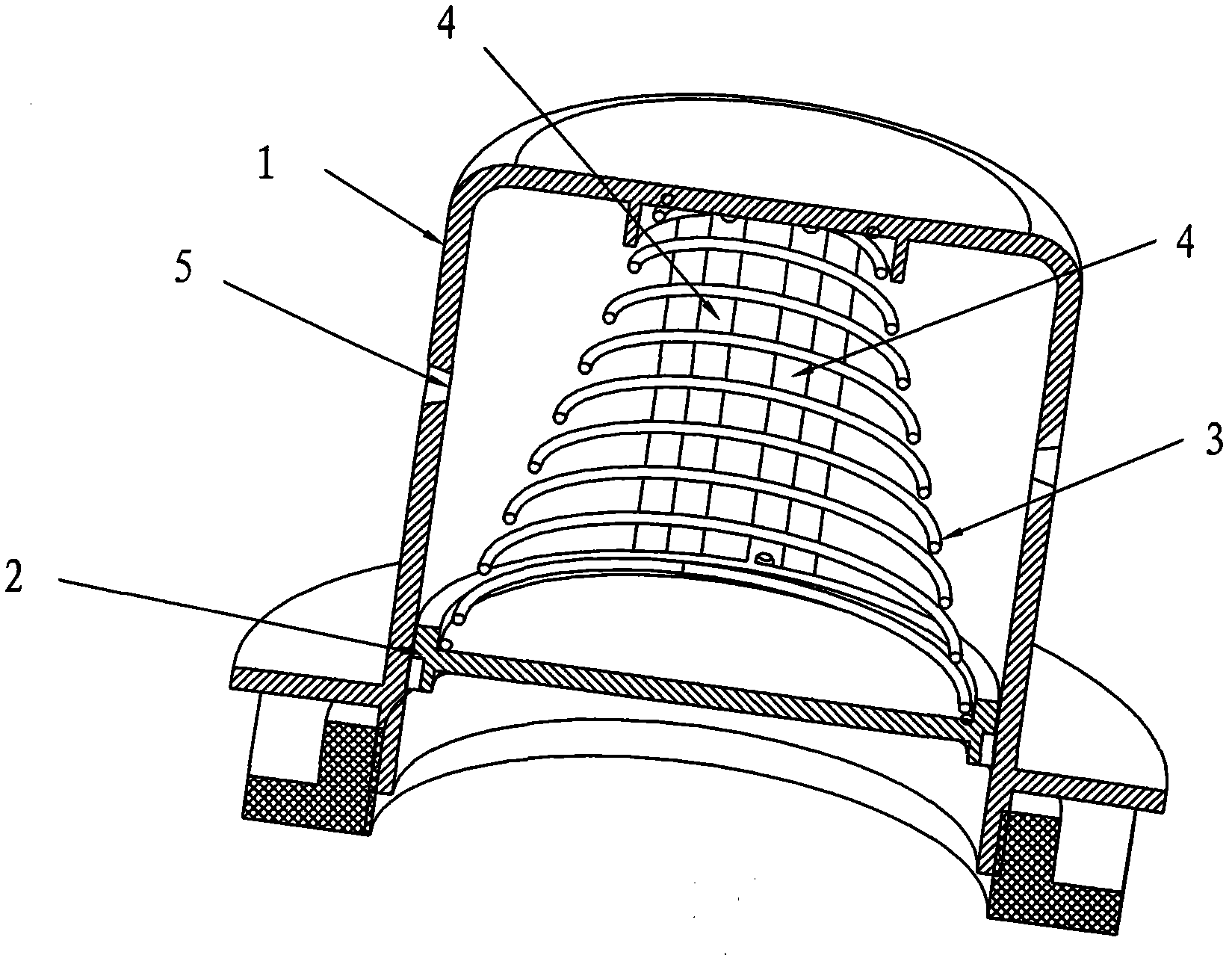

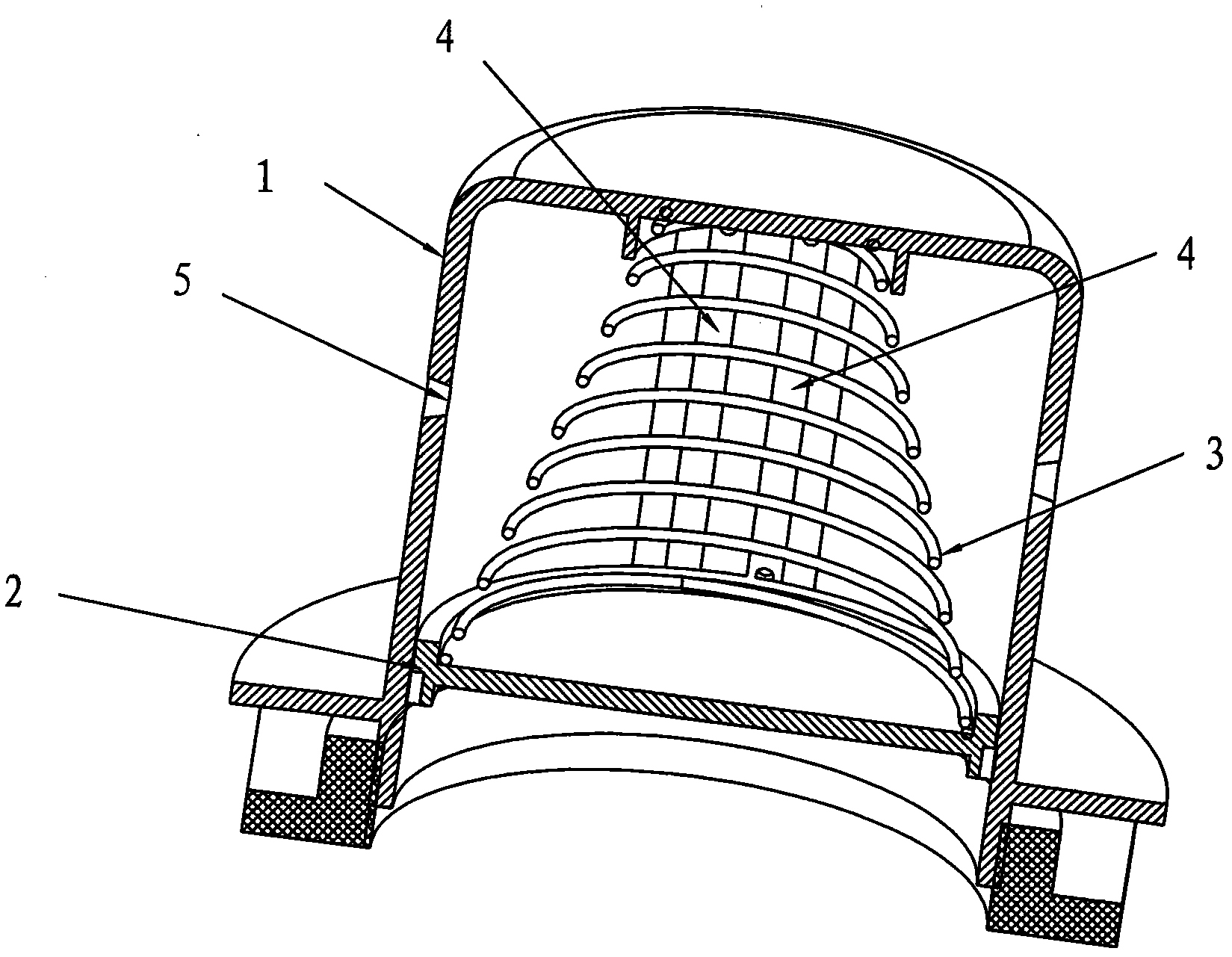

[0012] Such as figure 1 Shown, a kind of pressure sensor that electric pressure cooker is used, it comprises and has lower opening cylinder 1, piston 2, pressure spring 3 and potentiometer;

[0013] Piston 3 is slidingly matched with cylinder 1 and is liquid-gas sealed. One end of pressure spring 3 cooperates with piston 2, and the other end cooperates with the top plate of cylinder 1; piston 2 drives the potentiometer, and the cylinder between piston 2 and the top plate of cylinder 1 The wall has a limit pressure relief hole 5.

[0014] Described potentiometer comprises two resistive strips 4, and two resistive strips 4 are arranged in parallel in a row, and two resistive strips 4 are arranged in the cylinder barrel 1 parallel to the axis of the cylinder barrel, and the resistive strips 4 are insulated from the cylinder barrel 1, Piston 2 is used as the connection l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com